Diamond machining equipment

A kind of processing equipment and diamond technology, applied in the field of diamond, can solve the problems of affecting the quality of diamond film, difficult to be found, temperature influence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

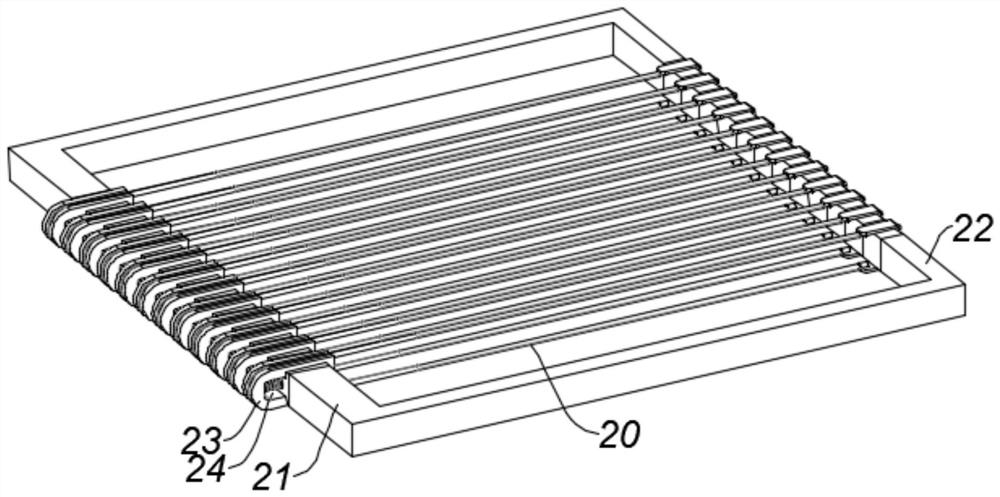

[0029] Such as figure 1 and figure 2 As shown, this embodiment provides a diamond processing equipment, including a vapor deposition furnace 1, and a hot wire mechanism 2 arranged in the vapor deposition furnace 1, the hot wire mechanism 2 includes a carrier, and several Hot wire 20 on. As for the vapor deposition furnace 1, there are a large number of documents published in the prior art, so its specific structure will not be described in detail here.

[0030] Such as figure 2 As shown, the entire carrier is a frame structure, and it at least includes a set of first installation beams 21 and second installation beams 22 arranged in parallel.

[0031] The first installation beam 21 is provided with a number of clips 23 for the heating wire 20 to bypass, wherein the number of clips 23 is the same as that of the heating wire 20, and the number of clips 23 is evenly distributed along the length direction of the first installation beam 21 .

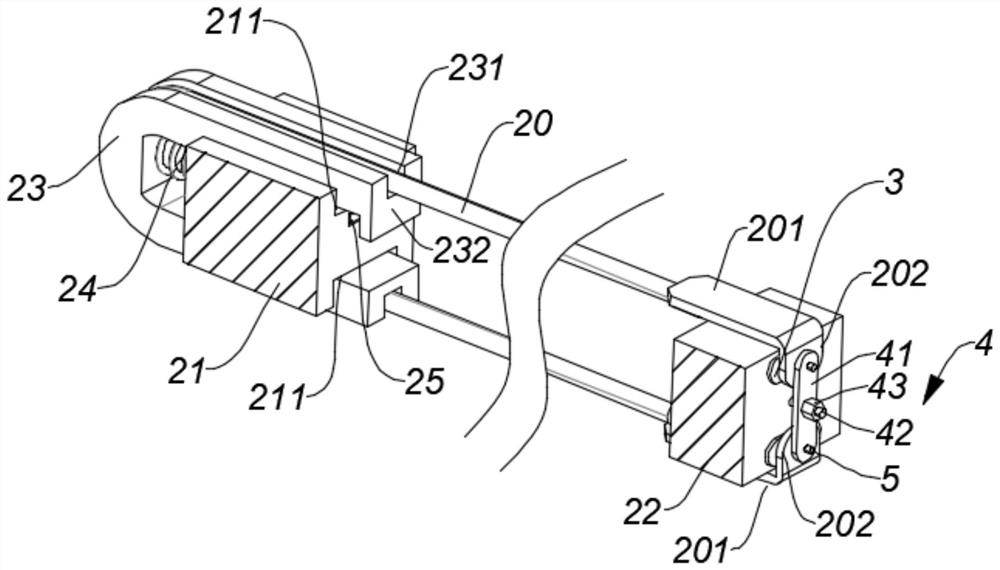

[0032] to combine image 3 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com