Tension control device for flexographic printing and operation method of tension control device

A tension control and flexographic printing technology, applied in the general parts of printing machinery, printing, printing machines, etc., can solve problems such as low printing efficiency, improve work efficiency, ensure work efficiency, and protect from damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

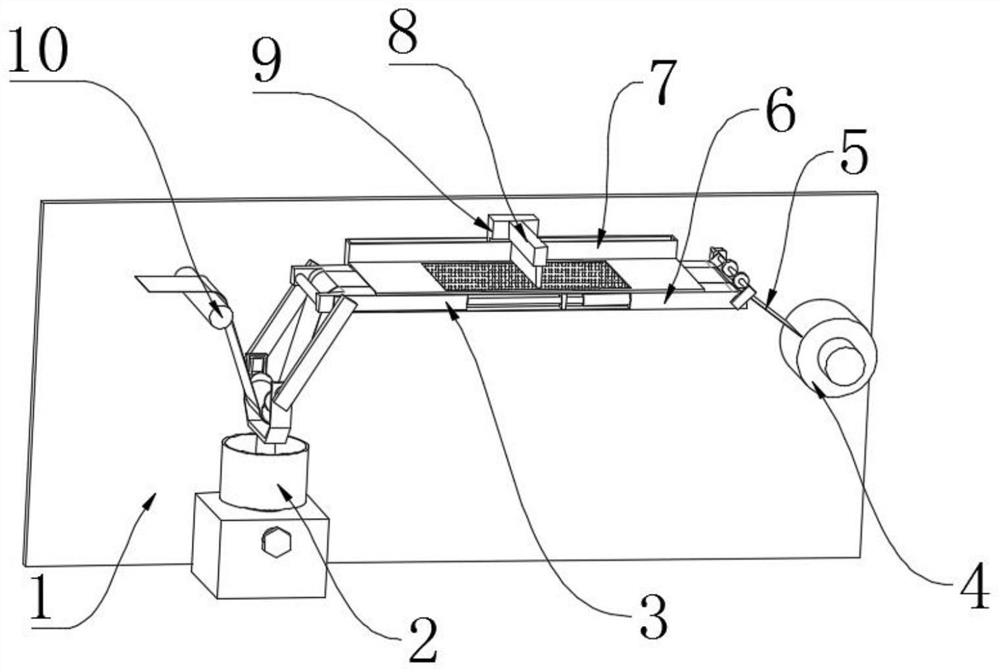

[0037] A tension control device for flexographic printing, such as figure 1 , figure 2 , Figure 4As shown, it includes a frosted frame 1, a tension buffer mechanism 2, and a flexographic plate 5; the outer wall of one side of the frosted frame 1 is rotatably connected with a guide roller 10; the outer wall of one side of the frosted frame 1 is fixedly connected with a parallel sliding table 7; The outer wall on one side of the slide table 7 is fixedly connected to the frosting table 6; the inner wall on one side of the grinding table 6 is rotatably connected to the limit roller 15; the inner wall on one side of the grinding table 6 is fixedly connected to the driving mechanism 3; the outer wall on one side of the driving mechanism 3 is rotatably connected to the tension The outer wall on one side of the buffer mechanism 2; the outer wall on one side of the frosted frame 1 is rotatably connected to the winding roller 4; the outer wall on the one side of the flex plate 5 is s...

Embodiment 2

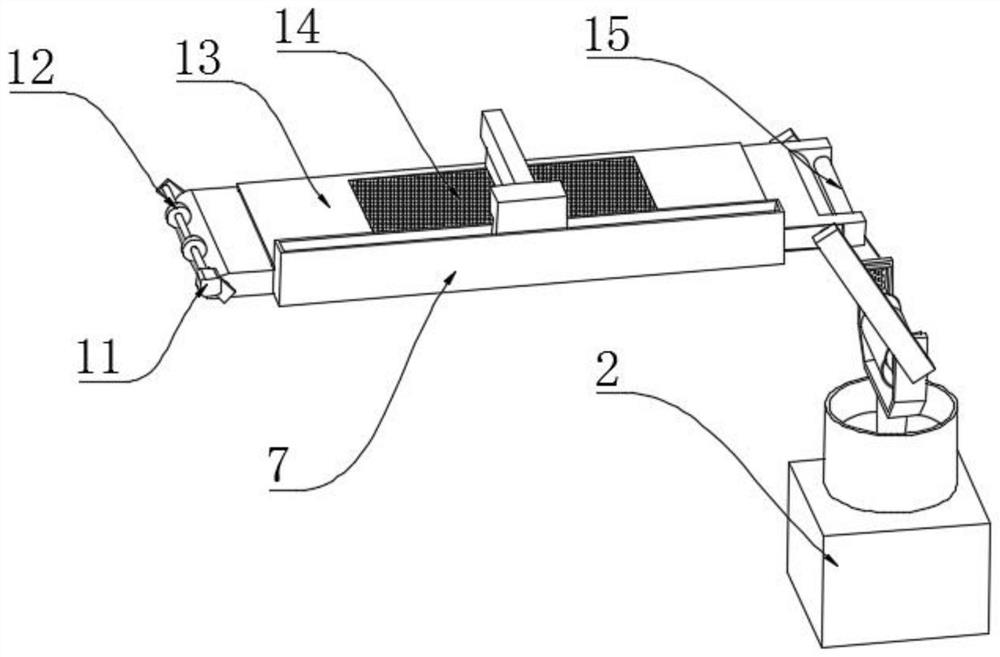

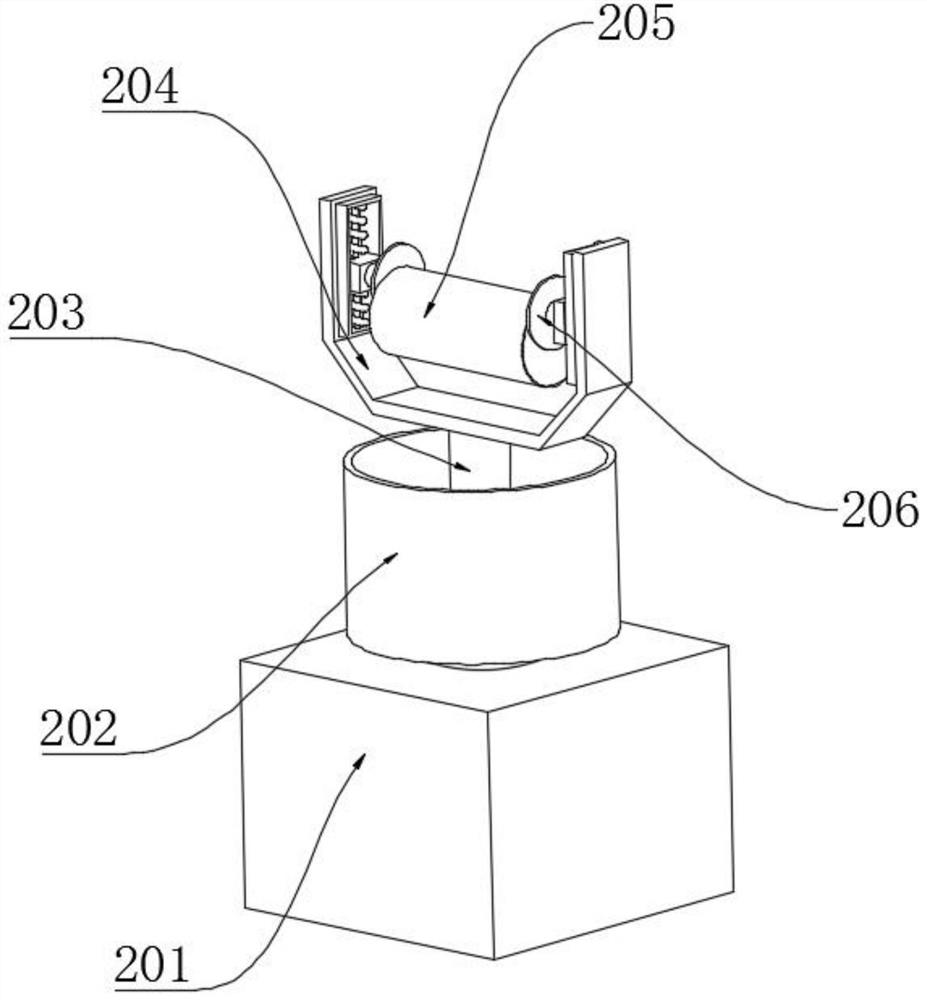

[0042] A tension control device for flexographic printing, such as Figure 3-5 As shown, in order to ensure the effectiveness of the work of the tension buffer mechanism 2; this embodiment makes the following additions on the basis of embodiment 1: the tension buffer mechanism 2 includes a water storage tank 201, a push cylinder 202, a lifting link 203, a support Folding rod 204, buffer tube 205, moving connecting plate 214; water storage tank 201 top inner wall is fixedly connected with penetrating tube 207; pushing tube 202 bottom end outer wall is fixedly connected with penetrating tube 207 top outer wall; pushing tube 202 bottom end inner wall is fixedly connected with Support column 208; the bottom inner wall of support column 208 is fixedly connected with telescopic spring 209; the outer wall of telescopic spring 209 top is fixedly connected with telescopic connecting rod 210; The outer wall of the bottom end of 214 is fixedly connected with a sealing gasket 215; the out...

Embodiment 3

[0045] A tension control device for flexographic printing, such as Image 6 As shown, for the effectiveness of the work of the driving mechanism 3; this embodiment makes the following additions on the basis of Embodiment 1: the driving mechanism 3 includes an electric telescopic rod 301, a limit connecting plate 302, a driving connecting rod 303, a rotating connecting rod Rod 304, electromagnet 305; the outer wall on one side of the electric telescopic rod 301 is fixedly connected to the inner wall on one side of the sanding table 6; the outer wall on one side of the limit connecting plate 302 is fixedly connected to the inner wall on one side of the sanding table 6; the outer wall on the other side of the electric telescopic rod 301 Fixedly connected to the outer wall on one side of the electromagnet 305; the outer wall around the drive connecting rod 303 is slidingly connected to the inner wall on one side of the frosting table 6; the outer wall on one side of the driving con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com