Drying device for polyester dyed elastic fabric production and drying method thereof

A drying device and elastic cloth technology, applied in the directions of removing liquid/gas/vapor by air jet method, equipment configuration for processing textile materials, removing liquid/gas/vapor by squeezing roller, etc. Uniform dyeing, inability to dry the fabric quickly and efficiently, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

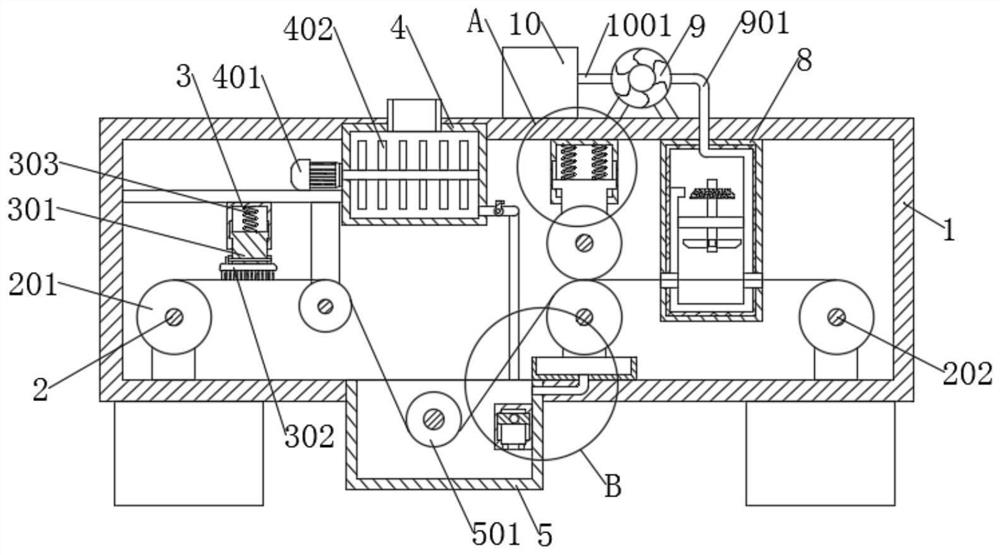

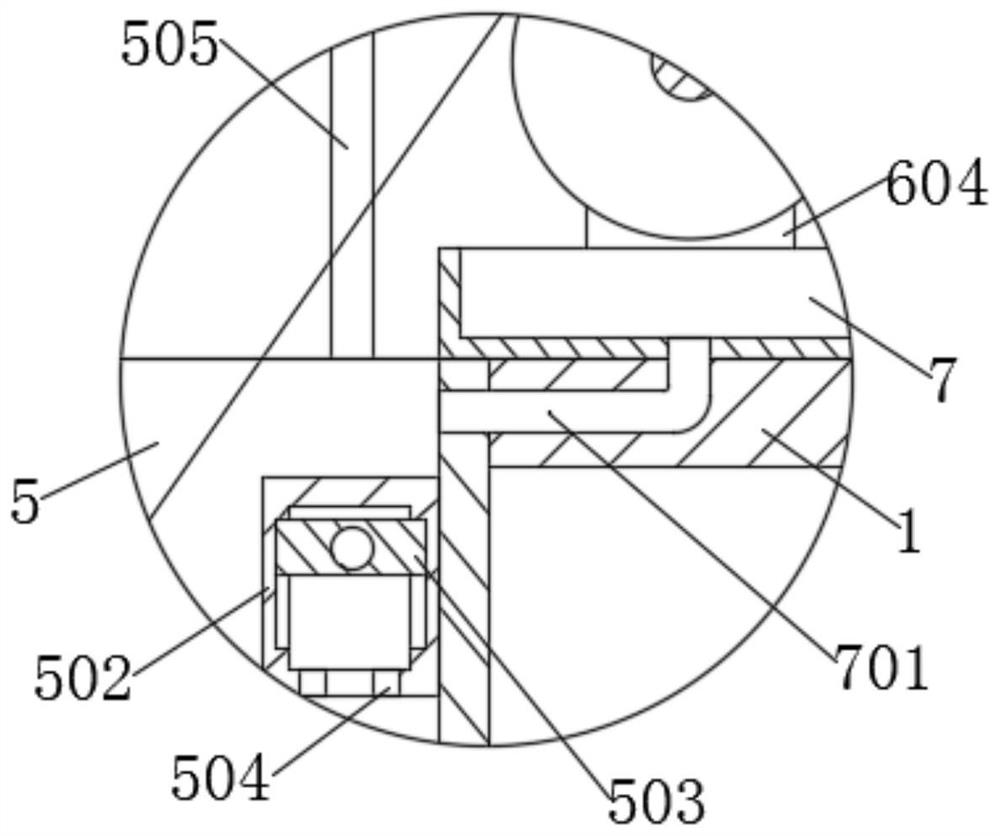

[0048] refer to figure 1 , image 3 with Figure 5 , a drying device for the production of polyester dyed elastic cloth, including a frame 1, and also includes:

[0049]A drying box 8 provided with a drying bin 806,

[0050] Wherein, an insulating layer 801 is arranged between the drying bin 806 and the drying box 8, and a heat conducting pipe 802 is arranged in the insulating layer 801;

[0051] The heating device is arranged on the frame 1 and is used to dry the cloth;

[0052] Dyeing pool 5 is arranged at the bottom of frame 1;

[0053] The dyeing roller 501 is rotatably connected in the dyeing pool 5;

[0054] An automatic liquid replenishing device is set in the dyeing pool 5; it is used to add dyeing liquid to the dyeing pool 5;

[0055] The mixing box 4 is arranged on the frame 1;

[0056] The stirring device is arranged in the mixing box 4, and is used for evenly stirring the dyeing solution;

[0057] The tensioning device is arranged in the frame 1 and is used...

Embodiment 2

[0064] refer to figure 1 , Figure 5 , a drying device for the production of polyester dyed elastic cloth, including a frame 1, and also includes:

[0065] A drying box 8 provided with a drying bin 806,

[0066] Wherein, an insulating layer 801 is arranged between the drying bin 806 and the drying box 8, and a heat conducting pipe 802 is arranged in the insulating layer 801;

[0067] The heating device is arranged on the frame 1 and is used to dry the cloth;

[0068] Dyeing pool 5 is arranged at the bottom of frame 1;

[0069] The dyeing roller 501 is rotatably connected in the dyeing pool 5;

[0070] An automatic liquid replenishing device is set in the dyeing pool 5; it is used to add dyeing liquid to the dyeing pool 5;

[0071] The mixing box 4 is arranged on the frame 1;

[0072] The stirring device is arranged in the mixing box 4, and is used for evenly stirring the dyeing solution;

[0073] The tensioning device is arranged in the frame 1 and is used for tensionin...

Embodiment 3

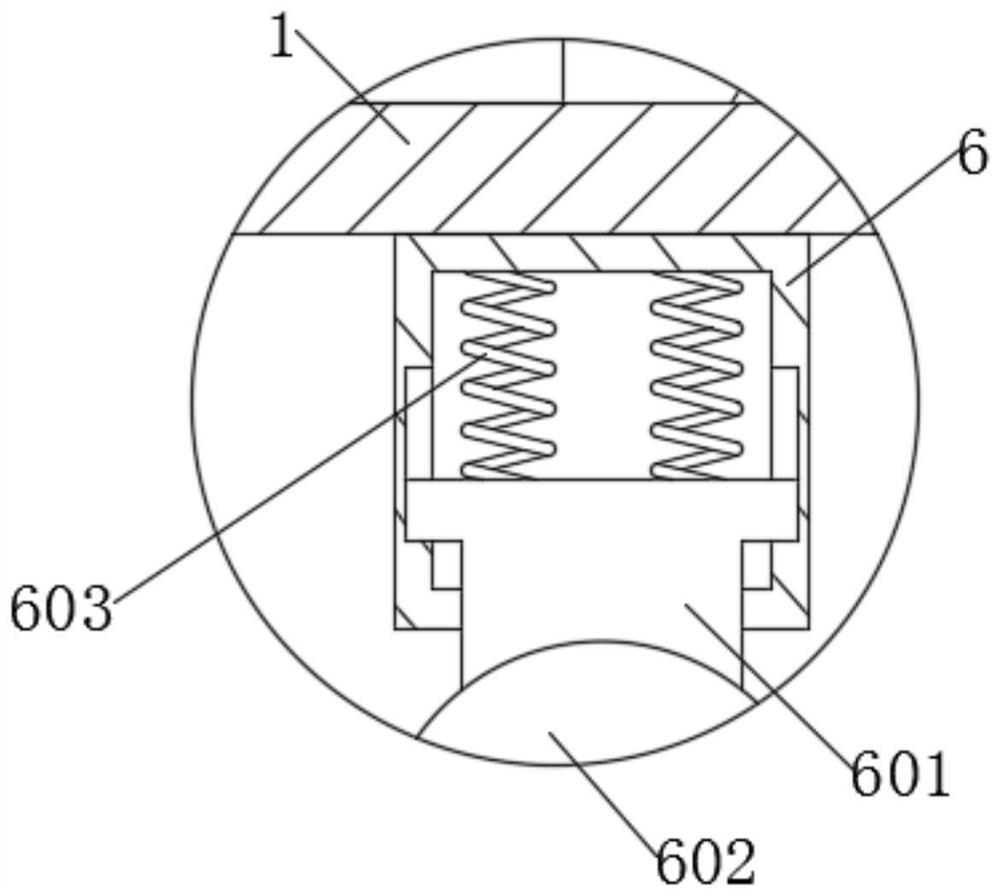

[0080] refer to figure 1 , figure 2 , image 3 with Image 6 , a drying device for the production of polyester dyed elastic cloth, including a frame 1, and also includes:

[0081] A drying box 8 provided with a drying bin 806,

[0082] Wherein, an insulating layer 801 is arranged between the drying bin 806 and the drying box 8, and a heat conducting pipe 802 is arranged in the insulating layer 801;

[0083] The heating device is arranged on the frame 1 and is used to dry the cloth;

[0084] Dyeing pool 5 is arranged at the bottom of frame 1;

[0085] The dyeing roller 501 is rotatably connected in the dyeing pool 5;

[0086] An automatic liquid replenishing device is set in the dyeing pool 5; it is used to add dyeing liquid to the dyeing pool 5;

[0087] The mixing box 4 is arranged on the frame 1;

[0088] The stirring device is arranged in the mixing box 4, and is used for evenly stirring the dyeing solution;

[0089] The tensioning device is arranged in the frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com