Manufacturing method and manufacturing equipment of prepreg

A technology of manufacturing equipment and manufacturing methods, applied in the direction of coating, etc., can solve the problem of unstable resin adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

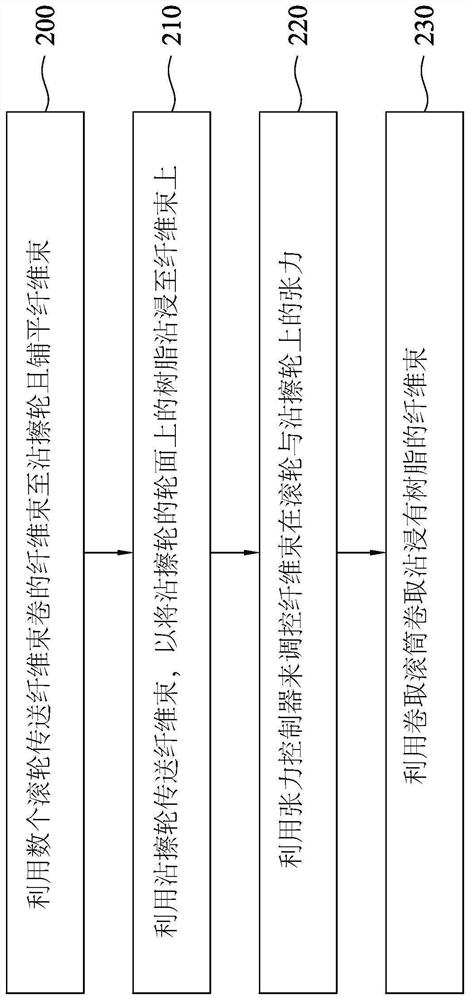

Method used

Image

Examples

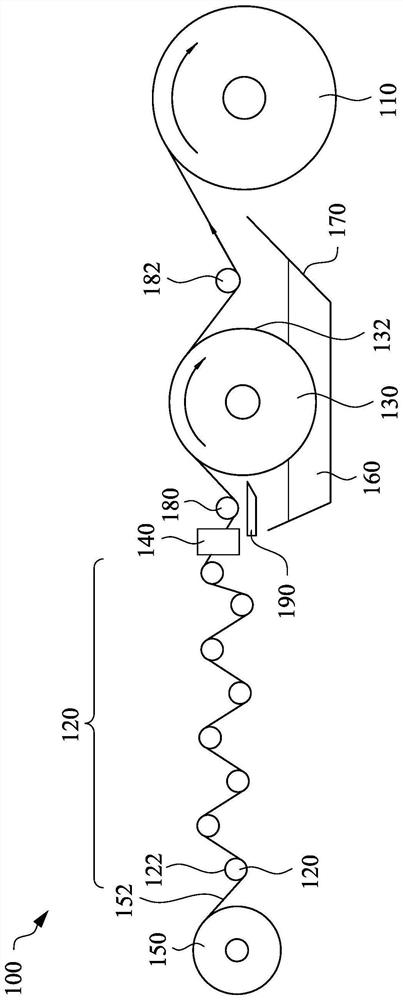

Embodiment 1

[0037] Embodiment 1 adds surface-treated rollers to transport the fiber bundles, wherein the rollers can be 2 to 12, for example, 5 to 8. In this example, for example figure 1 Measure the width of the fiber bundle between the tension controller 140 and the adjusting roller 180, and observe the ear-folding condition of the fiber bundle, and the results are listed in Table 1 below. Among them, the width of the fiber bundle is measured every 30 seconds, and the average value of 20 measurements; and the number of ear folds is the number of ear folds that occur in the fiber bundle in a length of 500 meters.

[0038] Table 1

[0039] scroll wheel Fiber bundle width (mm) Number of ear folds (times) none 7.9 13 have 10.4 4

[0040] It can be seen from Table 1 that the fiber bundles can be effectively paved by using the rollers to assist the fiber bundles, so the width of the fiber bundles is larger than that of the fiber bundles without rollers. In a...

Embodiment 2

[0041] Example 2 A tension controller was added to observe the hairiness of the fiber bundle, and the observation results are listed in Table 2 below. Here, the amount of hairiness is the amount of hairiness that appears in a fiber bundle with a length of 500 meters.

[0042] Table 2

[0043] Tension controller Hairiness (g) none 0.5~1 have almost none

[0044] It can be seen from Table 2 that after the tension controller is added, the tension on the fiber bundle is stable, so the fiber bundle has almost no hairiness, and its hairiness is obviously less than that of the fiber bundle without tension controller to adjust the tension.

Embodiment 3

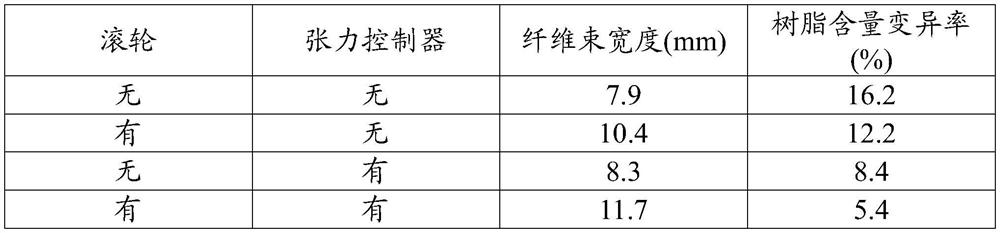

[0045] Embodiment 3 adds rollers and tension controllers at the same time. In this embodiment, the same as for example figure 1 Measure the width of the fiber bundle between the tension controller 140 and the adjusting roller 180, and measure the variation rate of the resin content of the prepreg made. The results are listed in Table 3 below. Among them, the width of the fiber bundle is measured every 30 seconds, and the average value of 20 measurements; the resin content variation rate is the resin content variation rate between 20 small units in the prepreg, and each small unit is 5cm*5cm.

[0046] table 3

[0047]

[0048] It can be seen from Table 3 that after the tension controller is added, the fiber bundle can be prevented from being too large or too small due to the inertial action of starting and stopping, and then the additional roller can be used to flatten the fiber bundle and expand the width of the fiber bundle , so that the impregnation state of fiber bund...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com