Optimal design method of motor car group wheel tread

A wheel tread and optimization design technology, applied in the direction of design optimization/simulation, calculation, special data processing applications, etc., can solve the problems of poor adaptability to rail profile changes, achieve the effect of alleviating dynamic problems and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

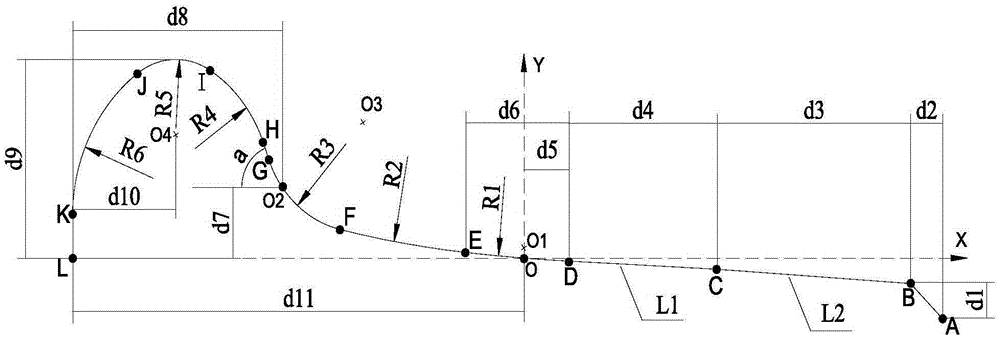

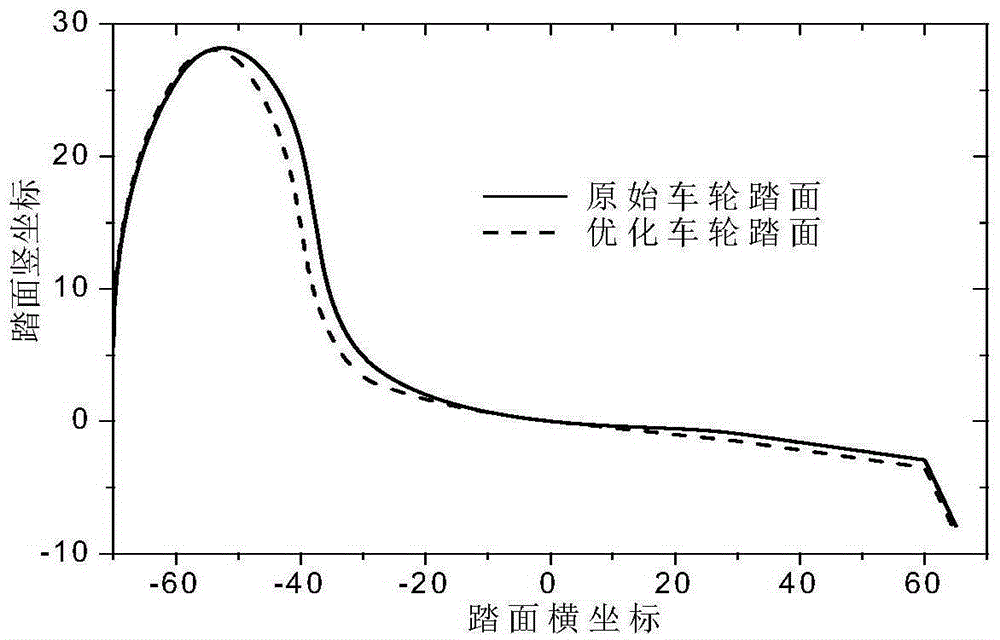

[0040] The improved design is carried out on the basis of the original wheel tread. First, through a large number of wheel-rail matching simulation tests, the wheel-rail contact relationship between the wheel tread and different rail profiles is found out. Through the analysis of the wheel-rail contact relationship, the common work of the wheel tread is found. In this area, the profile of the common working area (-15mm ~ 15mm) of the optimized wheel tread is selected to basically coincide with the original wheel tread; secondly, in order to improve the adaptability of the wheel tread to the unpolished steel rail, the circular slope of the throat root of the wheel tread needs to be adjusted Reduction: Therefore, the rim thickness d8 of the optimized wheel tread is determined to be 32.5mm, which can reduce the slope of the root of the rim, so that when the optimized wheel tread matches the rail with protruding rail shoulder and is not polished, it is not easy to produce excessive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com