Preparation of silver nanometer electrodes

A silver nano-electrode technology, applied in the field of nano-materials, can solve the problems of high price, difficult mask production, easy deformation of the mask, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

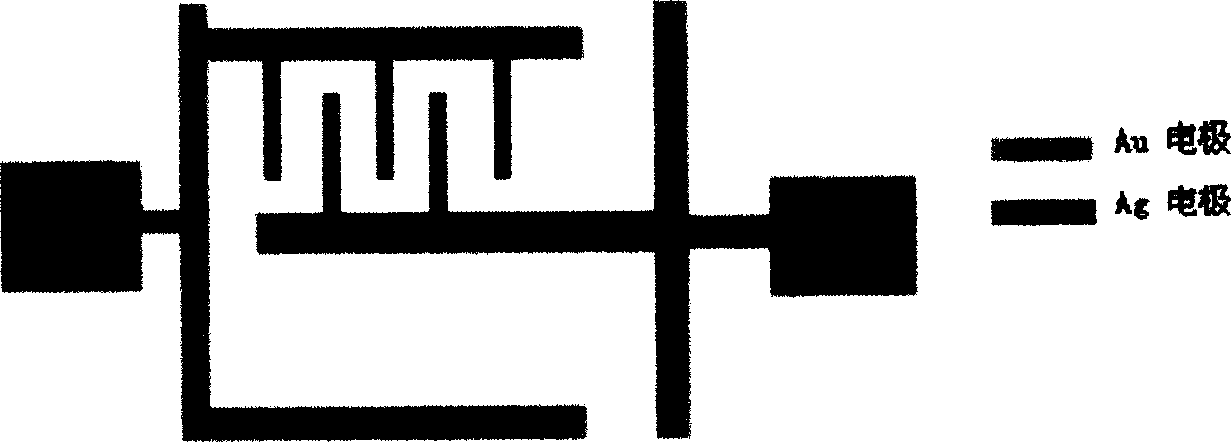

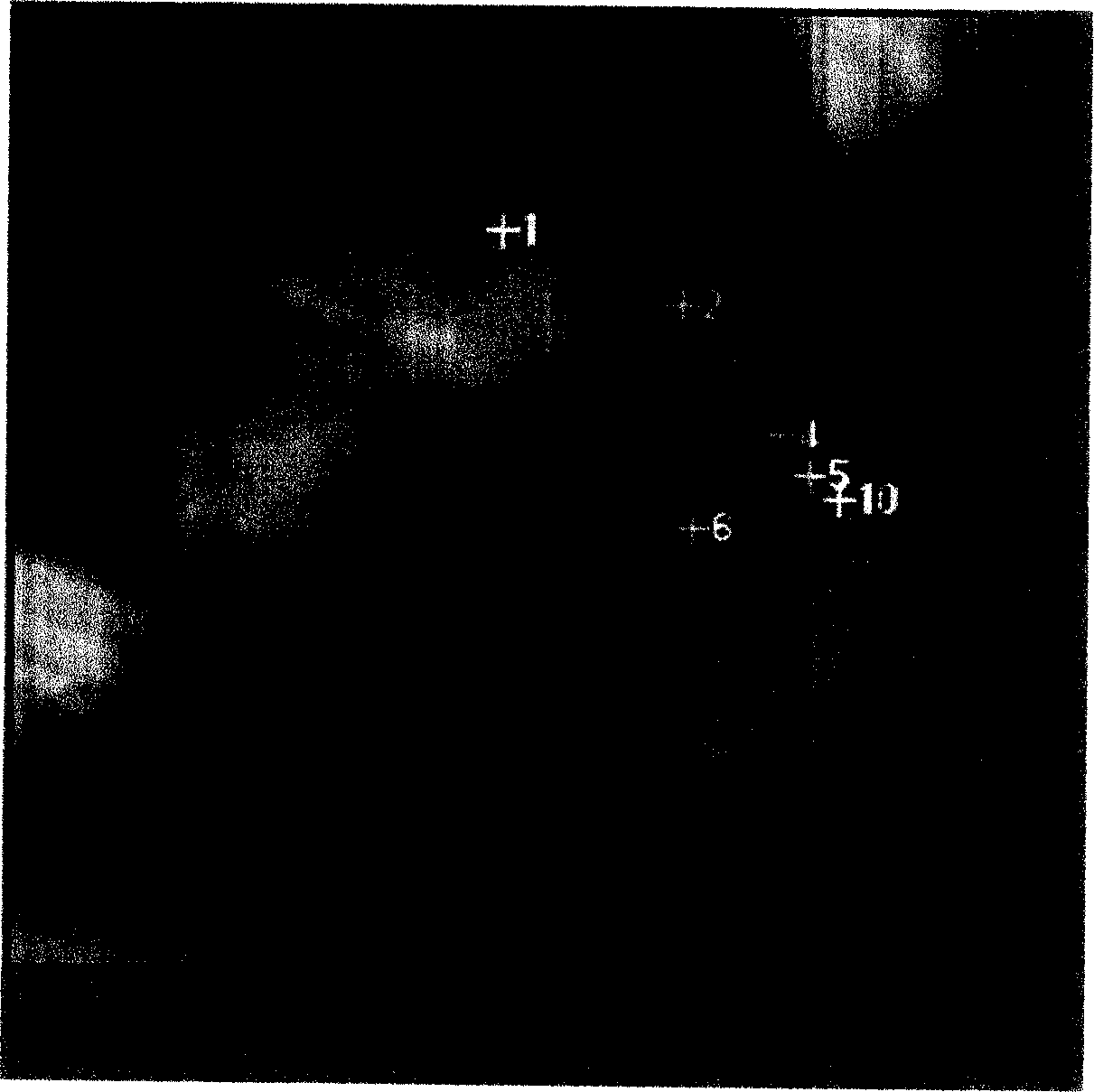

[0011] Embodiment, a kind of preparation method of silver nano-electrode, comprise the comb-shaped gold electrode etching (on the P-type Si (100) substrate, plate the comb-shaped gold electrode of 2-20um spacing by the method of photolithography), also comprise ( 1) Self-assembly substrate preparation: take the above-mentioned silicon substrate that has been ultrasonically treated in an organic solvent and washed with water, put it in a Piranha solution, wash it with water and dry it with a non-oxidizing gas, then treat it with an OTS solution and wash it with an organic solvent Cleaning; (2) nanowire etching: use the conductive atomic force microscope current simultaneous measurement mode to etch nanowires on the self-assembled substrate, and the radius of curvature of the needle tip is less than 50 nanometers; (3) nanowire generation: the etched substrate Soak in silver acetate aqueous solution, take out and soak in ethanol for a short time, then soak in sodium borohydride aq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com