Lotus nut husking lever device of husking machine

A sheller and lever technology, which is applied in the fields of shelling, pod removal, food science, etc., can solve the problems of poor economy, high damage rate and rework rate of meat lotus, unreasonable structure, etc., and achieve low rework rate, lotus The effect of good meat quality and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

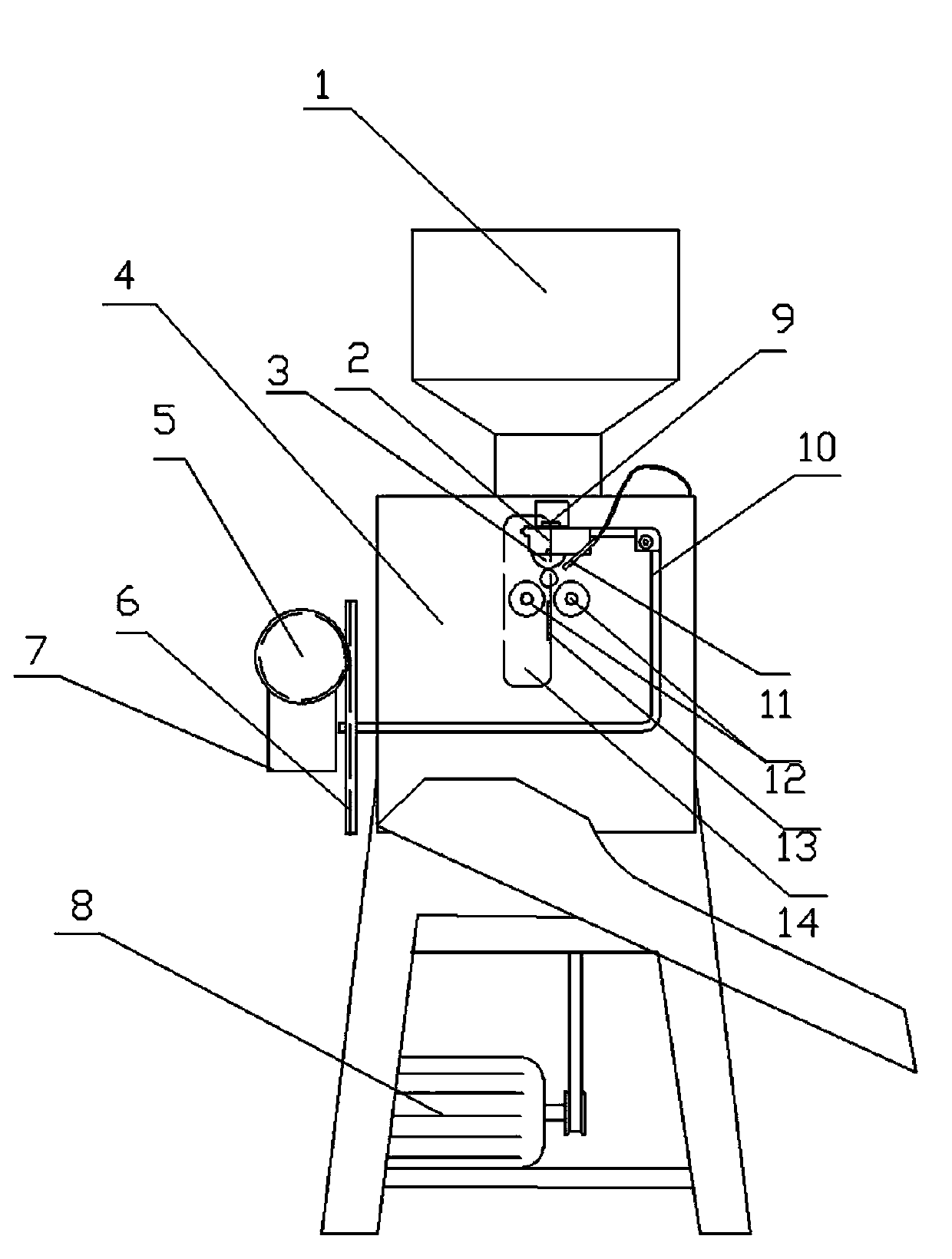

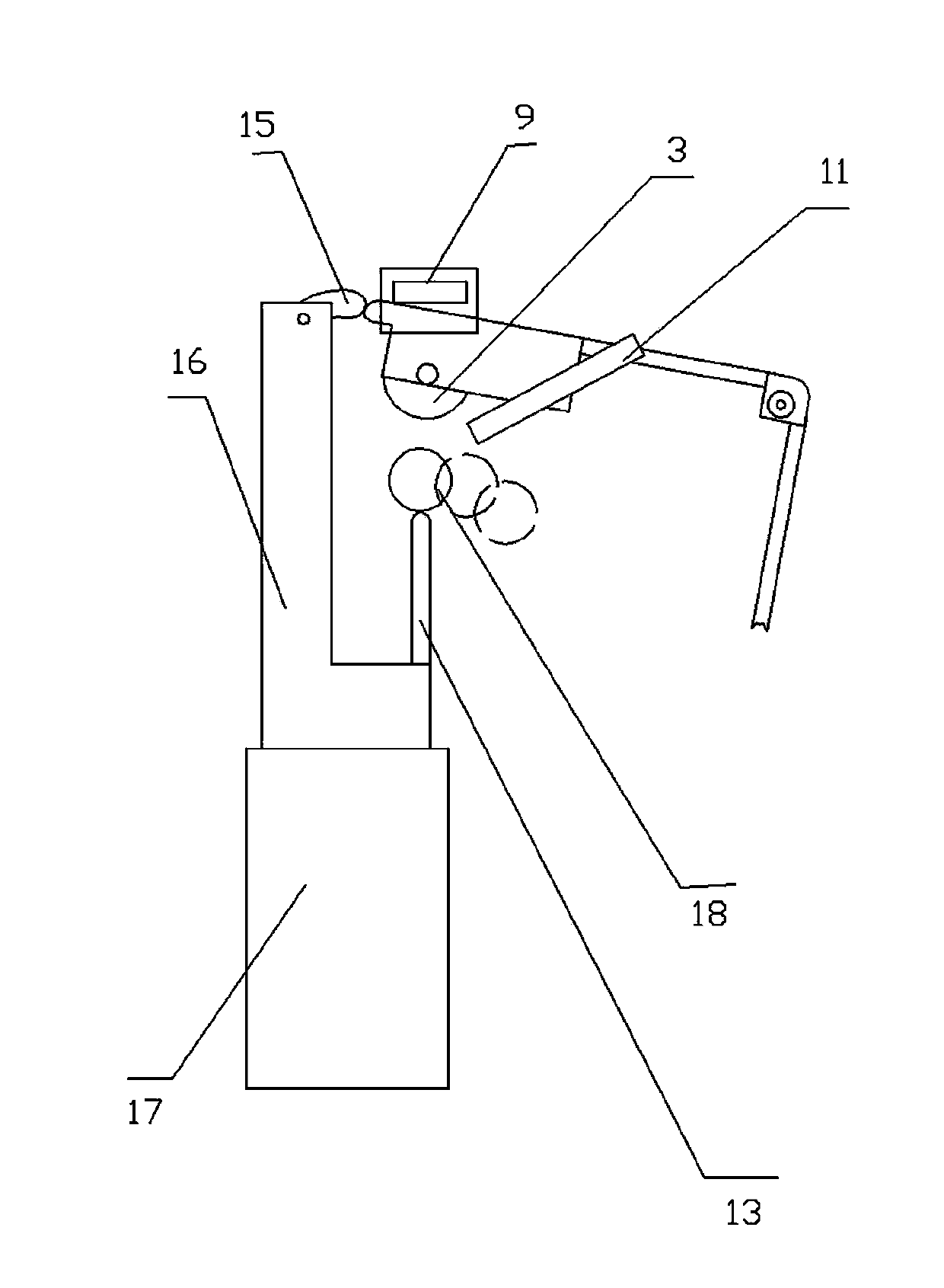

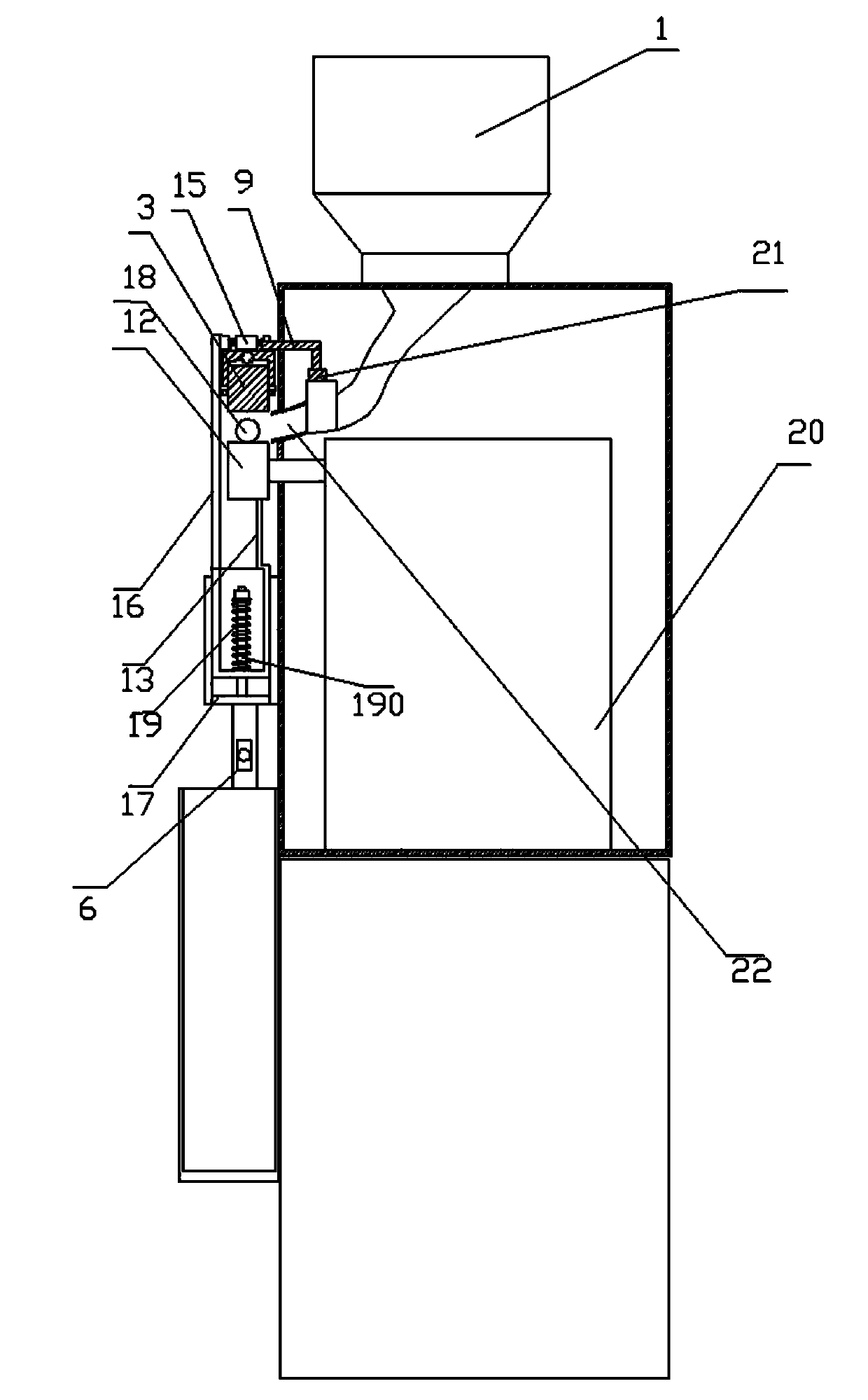

[0011] Example: see figure 1 , figure 2 , image 3 , Fig. 4, the automatic lotus seed peeling machine that the present invention applies is made of frame 4, main motor 8, executive motor 7, hopper 1 etc. A pair of co-rotating rollers 12 driven by a gear transmission mechanism 20 is arranged on the front of the frame 4 , and the hob wheel 3 is arranged above the pair of co-rotating rollers 12 located on the front of the frame. The side of the frame is provided with an executive motor, and the elevating rack 6 is vertically arranged on the side of the frame 4 . The front of the frame 4 is provided with a lotus stripping lever 10 bent into a "U" shape, the fulcrum of the lotus stripping lever 10 is fixed on the front of the frame 4, and the end of the resistance arm of the lotus stripping lever 10 is provided with a hob wheel frame 2. The hob wheel frame 2 is provided with a hob wheel 3, and the power arm of the lotus peeling lever 10 extends to the side of the frame 4.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com