Automatic pipe cutting machine

A pipe cutting machine, fully automatic technology, applied to turning equipment, turning equipment, metal processing equipment, etc., can solve the problems of unreachable dimensional accuracy, high labor intensity, waste of raw materials, etc., achieve high production efficiency, save labor, save The effect of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

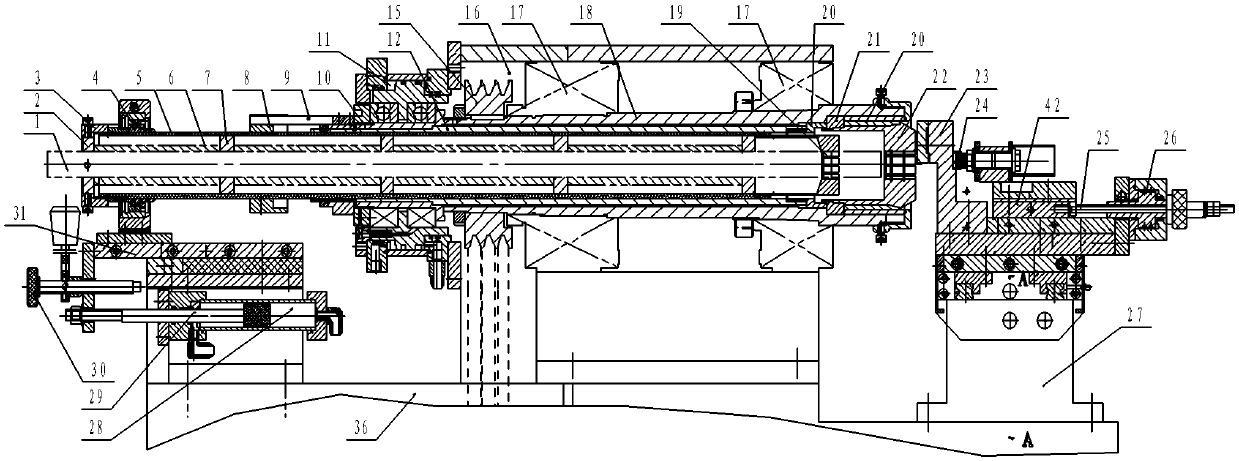

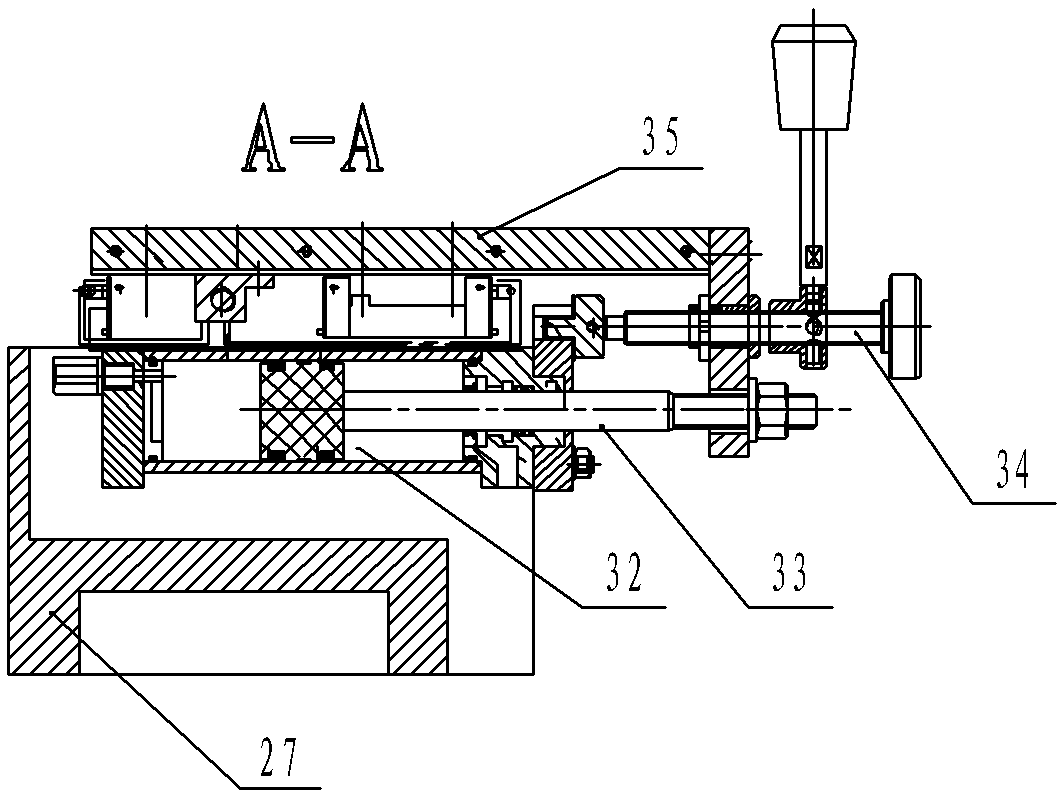

[0030] Describe the present invention in detail below in conjunction with accompanying drawing:

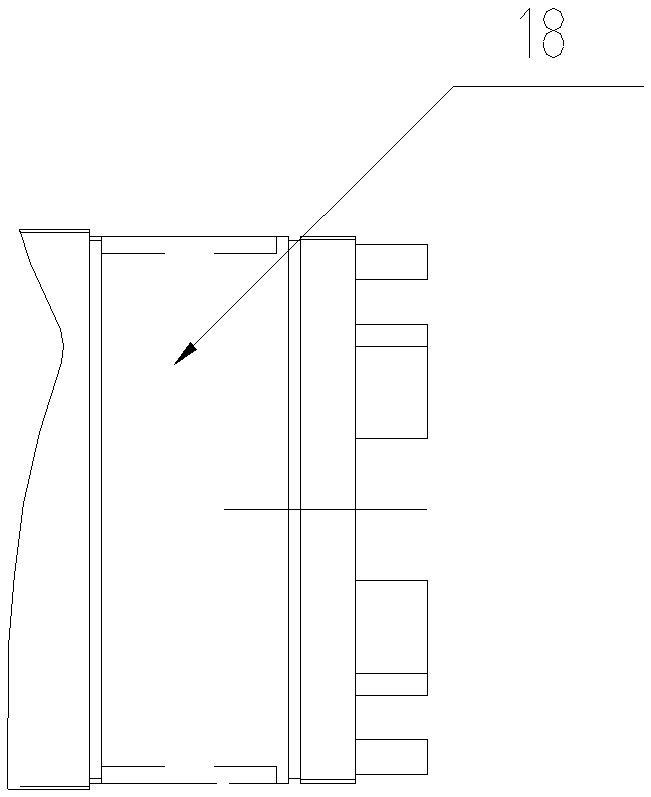

[0031] like Figure 1-2 As shown, this machine includes a hydraulic control system and an electrical control system. A headstock 16 and a tool rest seat 27 are provided on the frame seat 36. A pair of bearing seats 17 are arranged in the headstock 16, and the main shaft 18 is statically fitted in a pair of In the bearing center hole of the bearing seat 17, a passive pulley 15 is fixed on the main shaft 18; an oil pump assembly and a motor are arranged in the inner cavity of the frame seat 36, and the driven pulley 15 and the driving pulley equipped on the motor are used The wheel belts are connected; the knife rest seat 27 is provided with a left and right moving carriage 42 and a front and rear movement carriage 35, and the knife rest 23 is arranged on the left and right movement carriages 42 and the front and rear movement carriages 35, and the left and right movement carriages ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com