A fully automatic pipe cutting machine

A pipe cutting machine, fully automatic technology, applied in the direction of turning equipment, auxiliary devices, manufacturing tools, etc., can solve the problems that cannot meet the high precision of production, the processing technology is difficult to complete, and cannot be directly cut and used, so as to achieve convenient processing parameters , Saving process time and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is further described below in conjunction with accompanying drawing and embodiment:

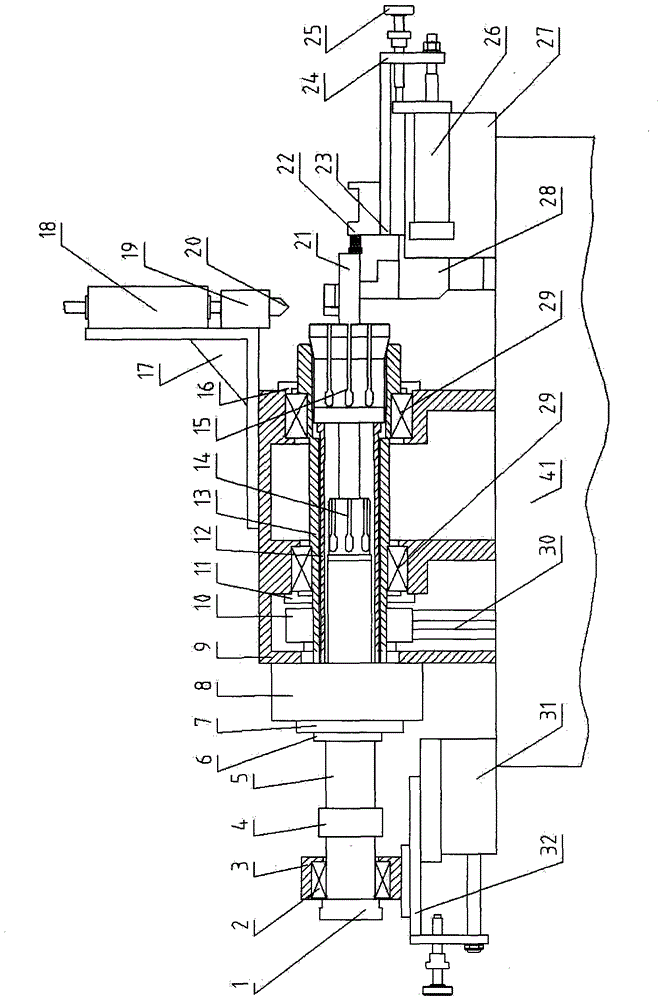

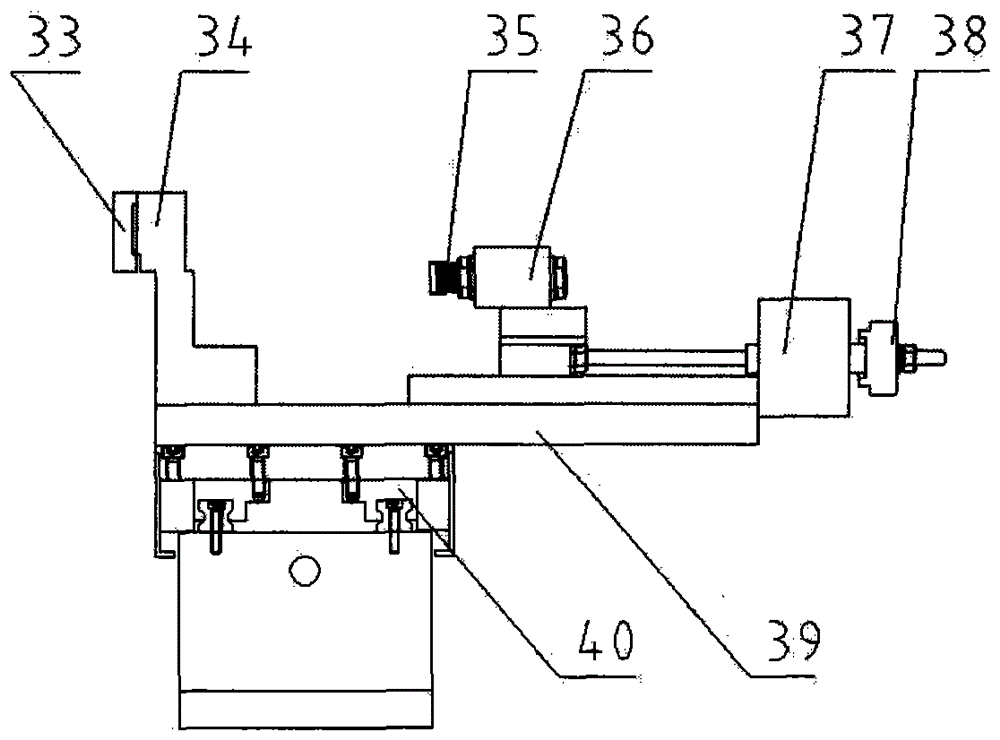

[0015] A full-automatic pipe cutting machine, including a hydraulic control part, an air circuit control part, and a PLC control part; There is a pair of bearing housings, the main shaft 13 is statically fitted in the center hole of the bearing II29 fitted in the pair of bearing housings, the bearing II29 is divided into a front bearing and a rear bearing, the front bearing is provided with a front bearing pressure plate, and the rear bearing is provided with a rear bearing. The end bearing pressure plate, the main shaft 13 is fixed with a driven wheel 10, the driven wheel 10 is connected with the driving wheel equipped with the motor with a belt 30, the oil pump assembly and the motor are installed in the frame seat 41, and the inner hole of the main shaft 13 is dynamically matched with a chuck. Tighten the tube 12, the chuck tightens the left peripheral step sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com