Gas-liquid pressurization swing type plate shearing machine

A technology of gas-liquid pressurization and gas-liquid pressurized cylinder, which is applied in the direction of shearing machine equipment, shearing devices, metal processing equipment, etc., can solve problems such as insecurity, and achieve the effect of low noise and improved shearing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail in conjunction with the accompanying drawings and preferred embodiments.

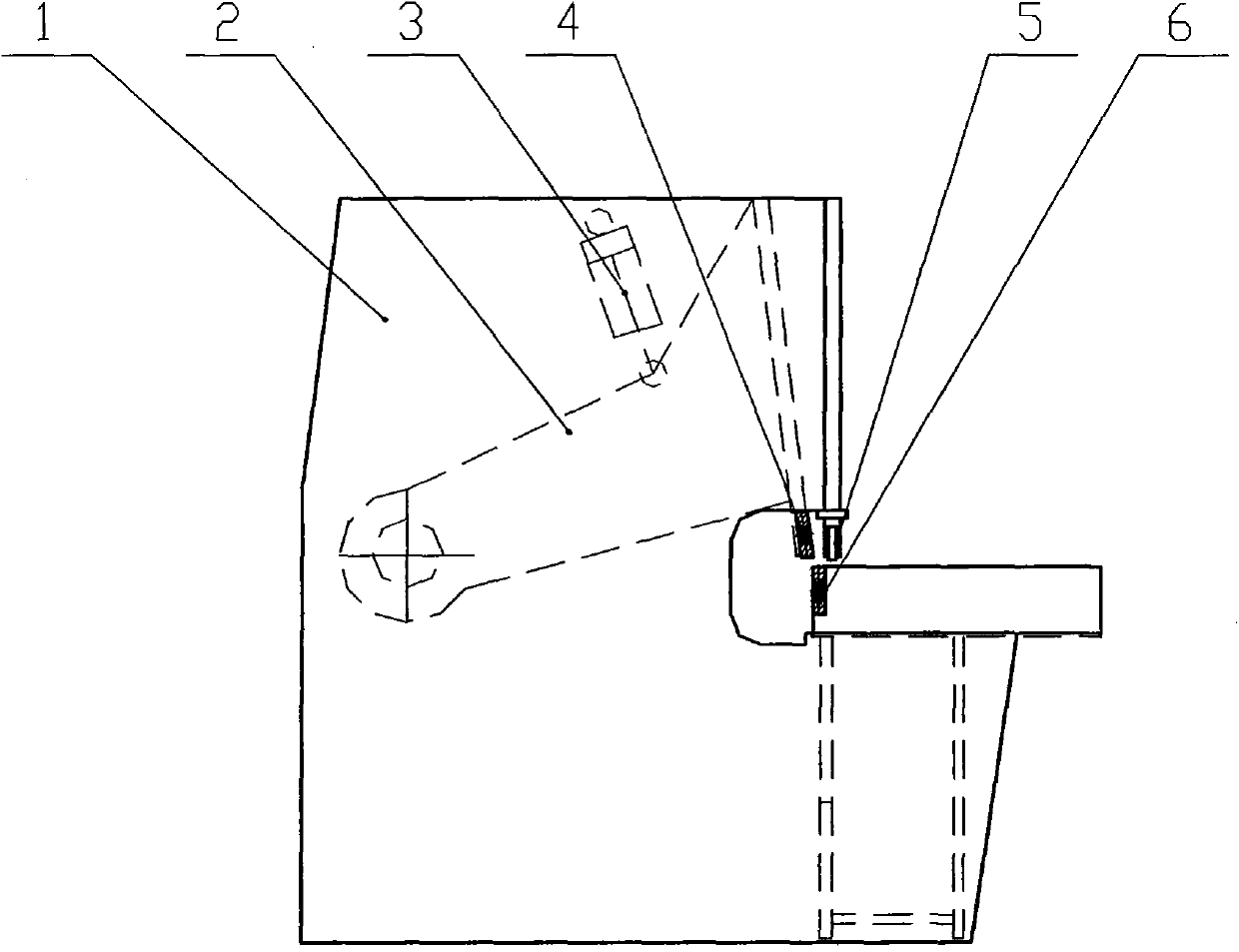

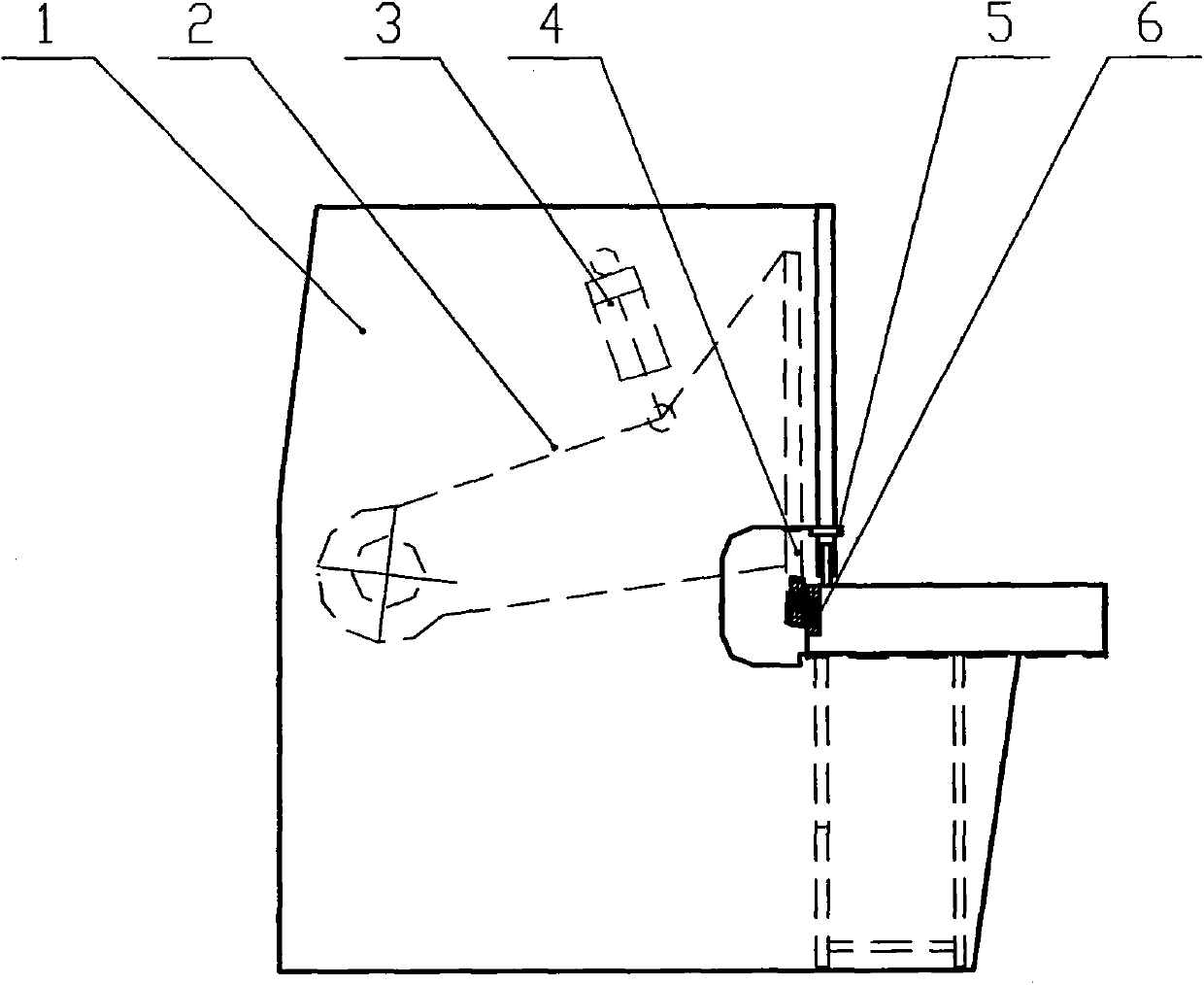

[0012] The gas-hydraulic pressurized pendulum shearing machine comprises a frame 1, an upper knife rest 2, a gas-liquid pressurized cylinder 3, an upper blade 4, a pressing cylinder 5, and a lower blade 6. The upper blade 4 is fixed on the upper knife rest 2, the lower blade 6 is fixed on the frame 1, and corresponds to the upper blade 4, and the pressing cylinder 5 is fixed on the frame 1, positioned above the lower blade 6, and the gas-liquid One end of the booster cylinder 3 is connected with the upper tool rest 2, and the other end of the gas-liquid booster cylinder 3 is connected with the frame 1.

[0013] The working process of the device is as follows: put in the workpiece to be cut, input the pneumatic signal, press th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com