Thin-wall curved surface surface pattern laser processing track solving method

A technology for processing trajectories and curved surfaces, applied in image data processing, details involving processing steps, complex mathematical operations, etc., can solve complex and time-consuming problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0120] The specific implementation manner of the present invention will be described in detail in conjunction with the technical scheme and the accompanying drawings.

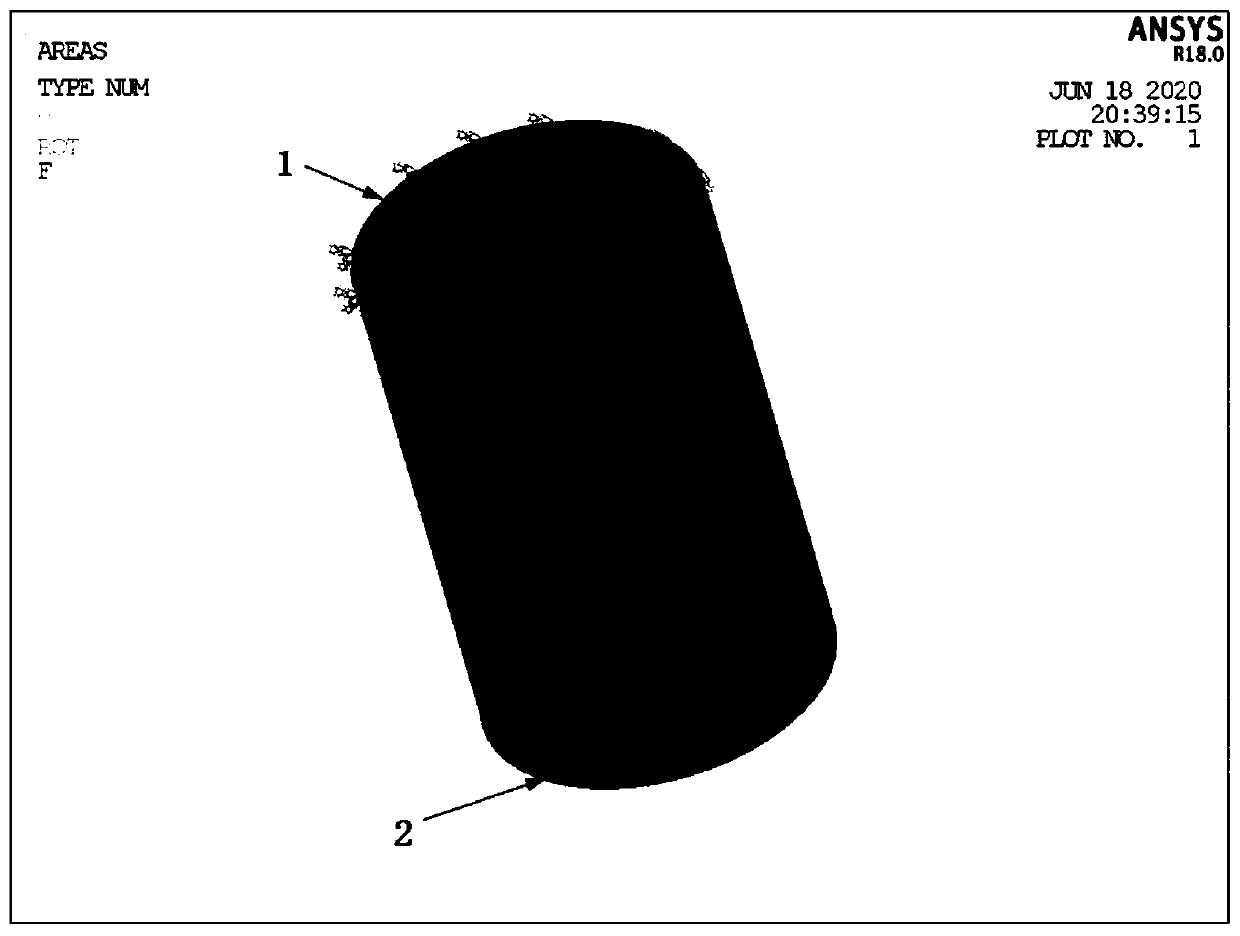

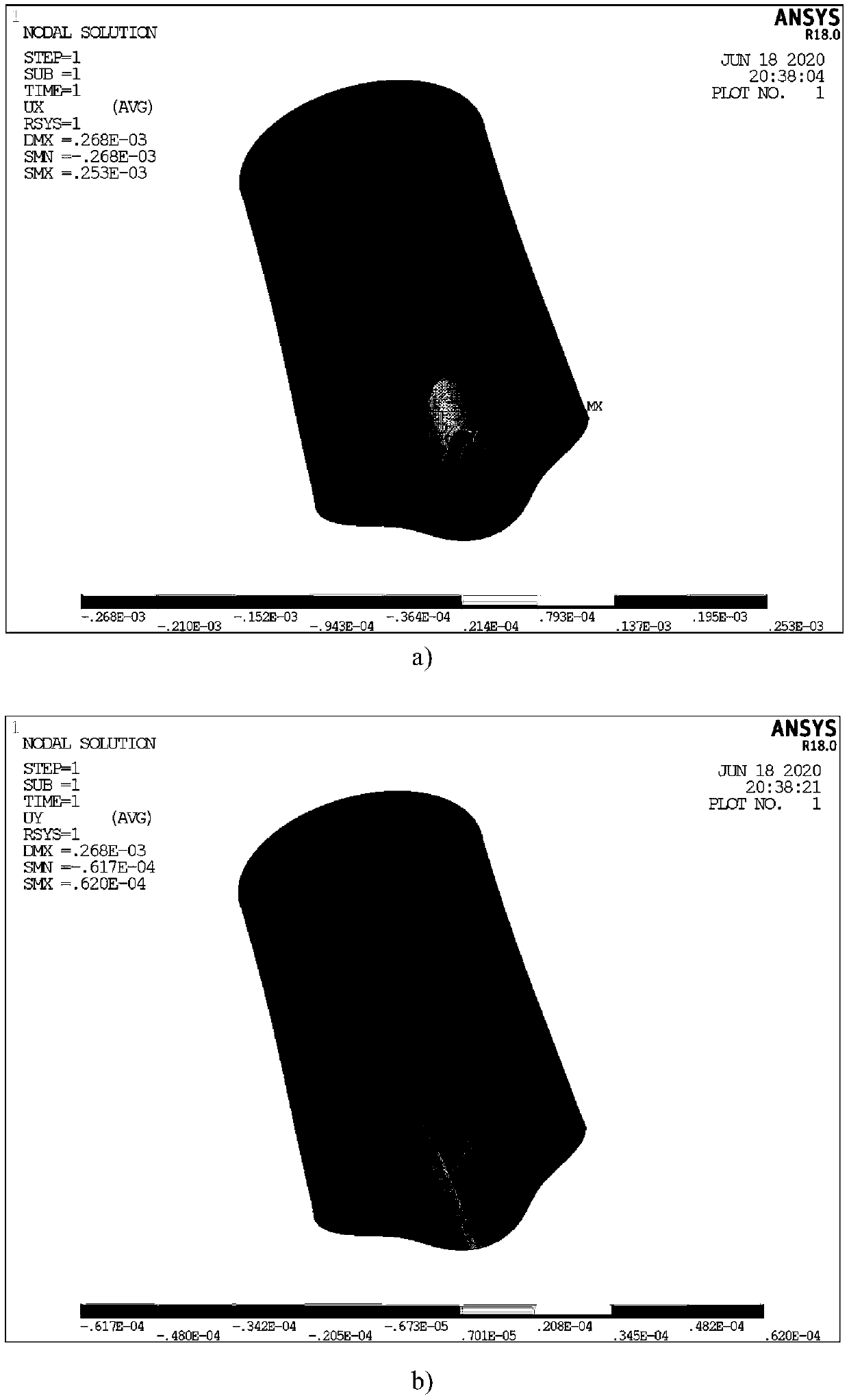

[0121] Embodiment: The selected material is 6061 aluminum alloy, the elastic modulus of the material is 71700MPa, the Poisson's ratio is 0.33, the outer diameter of the thin-walled cylindrical part is 0.098m, the height is 0.15m, and the thickness is 0.001m, and the seven-leaf plum blossom curve is processed on its surface , the implementation process of the present invention will be described in detail below.

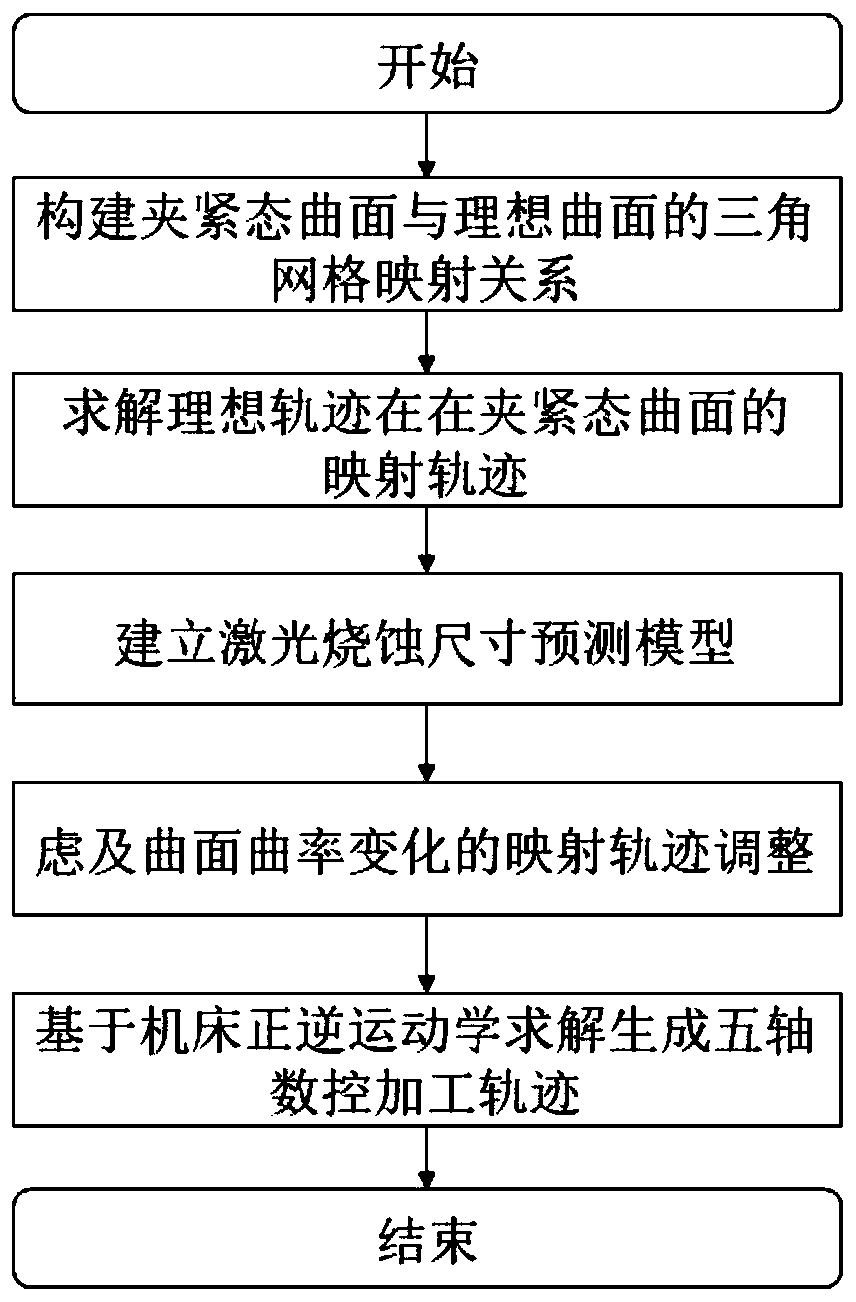

[0122] Thin-wall curved surface parts have low rigidity, and are prone to elastic deformation in the clamped state. During the process of surface pattern processing on thin-wall curved surfaces, it is easy to cause pattern curve processing errors. To solve this problem, a laser processing track for surface patterns on thin-wall curved surfaces is invented. The solution method, the overall process of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com