Intelligent cutter of integrated small three-way cutting force measurement system

A measurement system and cutting force technology, applied in the direction of tools for lathes, measuring/indicating equipment, turning equipment, etc., can solve the problem of inability to meet the requirements of measurement accuracy and sensitivity for ultra-precision machining applications, insufficient industrial practicability, and installation space. Restricted and other problems, to achieve the effect of ultra-precision adaptive intelligent processing, online real-time perception monitoring, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

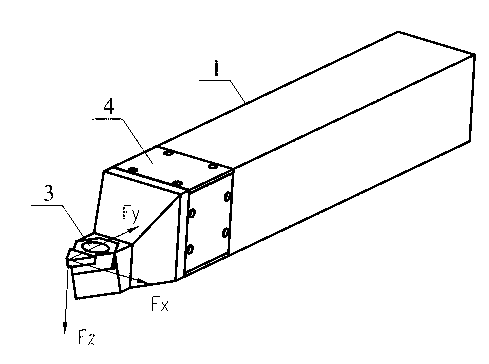

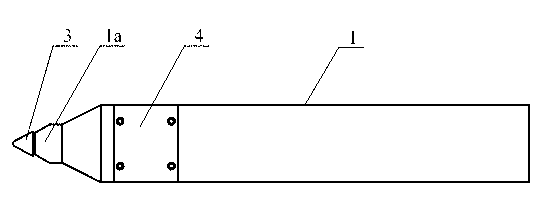

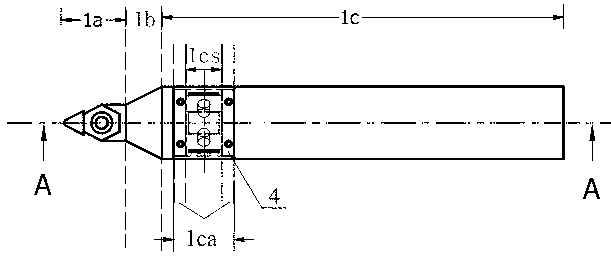

[0029] Specific implementation mode one: as Figure 1-Figure 4 As shown, an intelligent tool integrating a micro three-way cutting force measurement system, the intelligent tool includes a tool holder 1 and a cutting blade 3, and the intelligent tool also includes a micro three-way cutting force measurement system 2, a sealing cover 4 And the signal interface end 5; the cutter bar 1 is composed of three parts: the cutter head 1a, the cutter bar main body 1c and the transition section 1b connecting the cutter head 1a and the cutter bar main body 1c; the cutting blade 3 is fixedly mounted on the cutter head 1a Above, the tip of the cutting blade 3 is located on the center line of the cutter bar main body 1c, and the upper surface of the cutting blade 3 coincides with the center plane of the cutter bar main body 1c; the front end of the cutter bar main body 1c is provided with a sensing and measuring section; The sensing and measuring section is provided with a force-measuring ca...

specific Embodiment approach 2

[0031] Specific implementation mode two: as Figure 1-Figure 7 As shown in the specific embodiment 1, an intelligent tool integrated with a micro three-way cutting force measurement system, the sensing measurement section consists of two packaging sections 1ca and an octagonal prism structure section between the two packaging sections 1ca Composed of 1cs, the centerlines of the octagonal prism structure section 1cs and the two encapsulation sections 1ca coincide with the centerline of the cutter bar main body 1c; the cross section of the encapsulation section 1ca is square, and the cross section of the encapsulation section 1ca is smaller than that of the cutter bar main body 1c Cross-section, the cross-section of the octagonal prism structure section 1cs is smaller than the cross-section of the package section 1ca, thereby forming a force-measuring concave cavity connected on the peripheral side of the cutter bar, the four interval sides 6a of the eight sides of the octagonal ...

specific Embodiment approach 3

[0032] Specific implementation mode three: as Image 6 and Figure 7 As shown, the intelligent tool integrated with the micro three-way cutting force measurement system described in the second specific embodiment, the four sensing sides 6a are symmetrically distributed on the central plane of the tool holder body 1c, the auxiliary side 6b and the sensing side 6a Set at a 45-degree angle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com