Inorganic flame retardant straw fiberboard and production method thereof

A straw fiber, inorganic flame retardant technology, applied in other household appliances, pretreatment of molding materials, household components, etc., can solve the problems of flammability, harm to human health, easy deformation, etc., and achieve low production cost and high production efficiency. , good strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

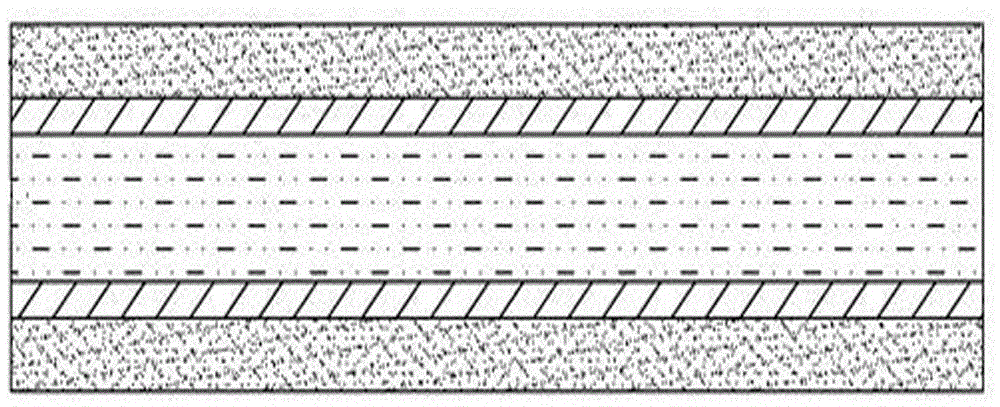

[0021] Embodiment 1, with reference to figure 1 , an inorganic flame-retardant straw fiber board, comprising three layers of straw fiber layers, a cotton gauze is arranged between adjacent straw fiber layers, and the cotton gauze and the straw fiber layers are bonded by an inorganic flame-retardant adhesive material layer, the The straw fiber layer is a plate-shaped material made of straw fiber and inorganic flame-retardant adhesive.

Embodiment 2

[0022] Example 2, in the inorganic flame-retardant straw fiber board described in Example 1: the thickness of the straw fiber layer is 6 mm, and the thickness of the cotton gauze is 0.2 mm.

Embodiment 3

[0023] Example 3, in the inorganic flame-retardant straw fiber board described in Example 1: the thickness of the straw fiber layer is 30 mm, and the thickness of the cotton gauze is 0.5 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com