Processing device for weed bodies between rows of ridging orchard

A treatment device and grass body technology, which is applied in the agricultural field, can solve the problems of low weeding efficiency, high labor intensity of staff, and inability to cut grass bodies, so as to achieve the effect of improving weeding efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The core of the present invention is to provide a device for treating grass between rows in a ridged orchard, so as to realize mechanization of weeding between rows in a ridged orchard, reduce labor intensity of workers, and improve weeding efficiency.

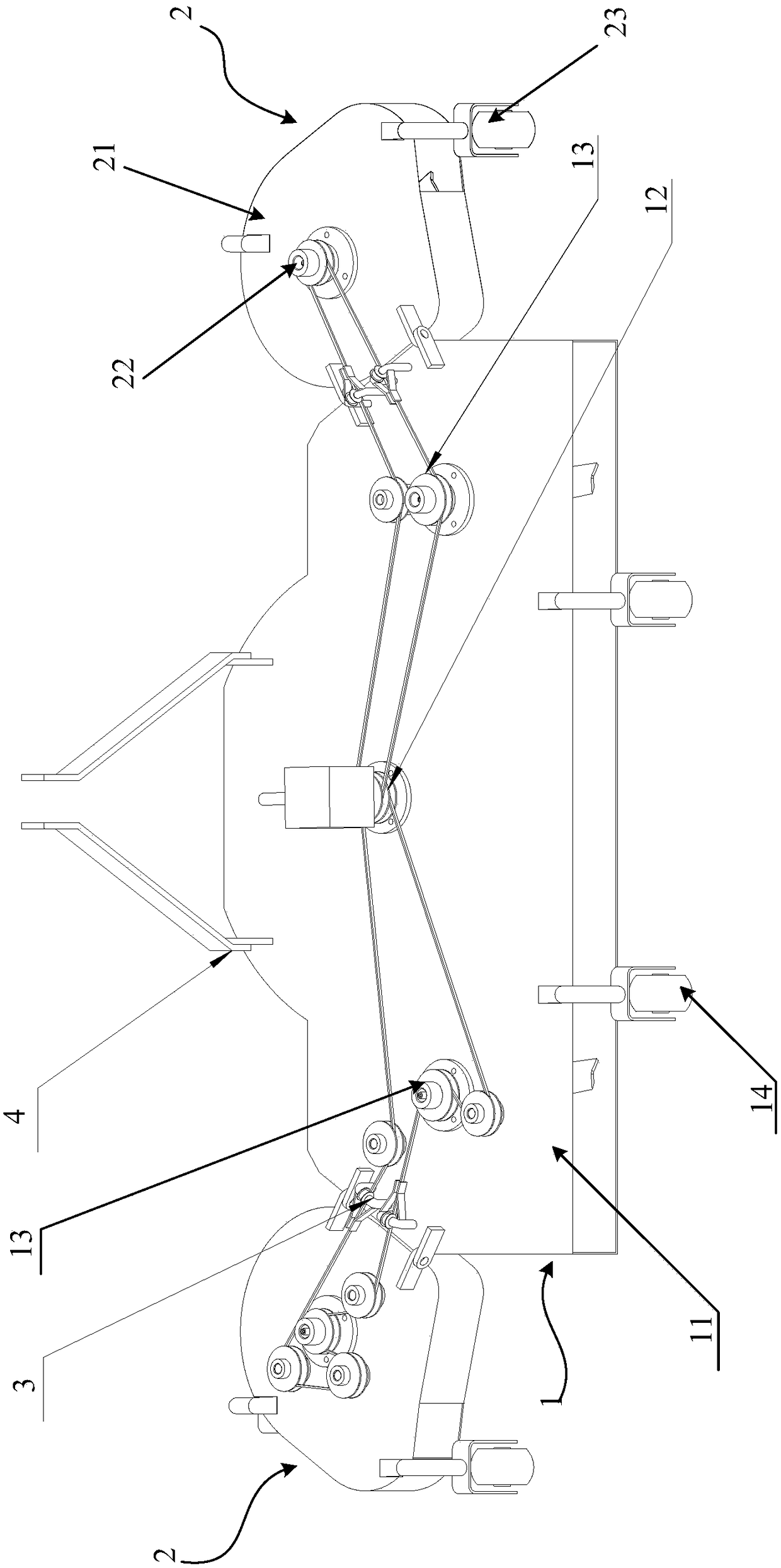

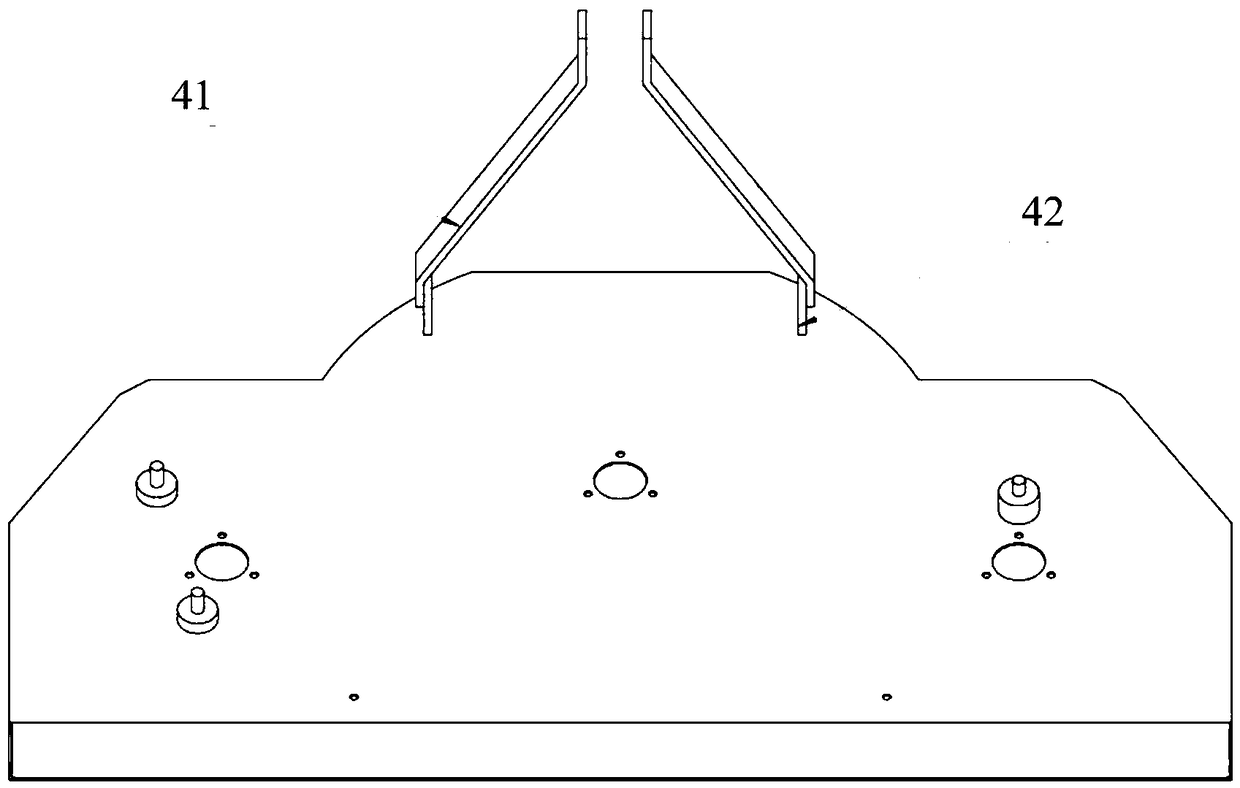

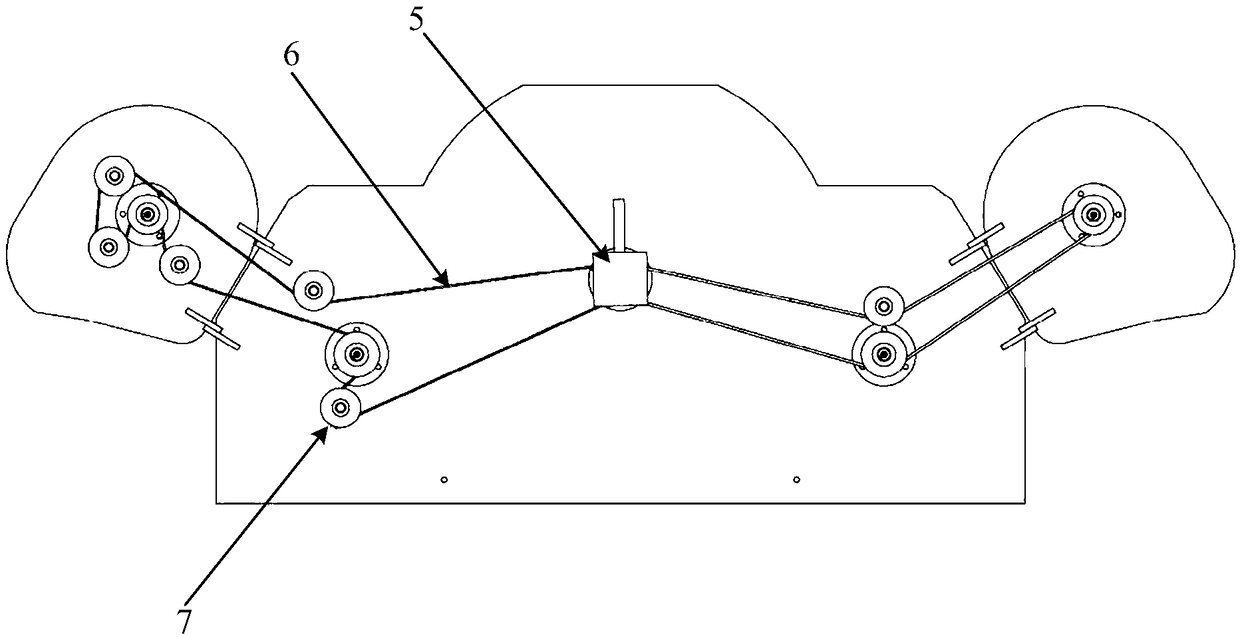

[0031] Please combine Figure 1 to Figure 5 To be understood, the so-called ridging orchard refers to an orchard that adopts a ridge cultivation method for fruit tree cultivation. The inter-row grass treatment device for a ridging orchard disclosed in the present invention includes a main mowing mechanism 1 and a floating mowing mechanism 2, wherein, The main body mowing mechanism 1 comprises a main body plate 11, a gearbox 5, a main mowing knife, a suspension device 4 and a main body ground wheel 14. The main body plate 11 is welded by a steel plate, and the thickness of the steel plate can be selected as required. The thickness of the steel plate is 3mm. The main mower is used to cut the grass body in the ditch. The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com