Manipulator of vertical sintering machine and application method thereof

A technology for sintering machines and manipulators, applied in the field of manipulators, can solve problems such as incapable output, low work efficiency, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046]The present invention will be described in more detail below with reference to schematic diagrams, wherein preferred embodiments of the present invention are shown, and it should be understood that those skilled in the art can modify the present invention described herein while still achieving the advantageous effects of the present invention. Therefore, the following description should be understood as the broad knowledge of those skilled in the art, but not as a limitation of the present invention.

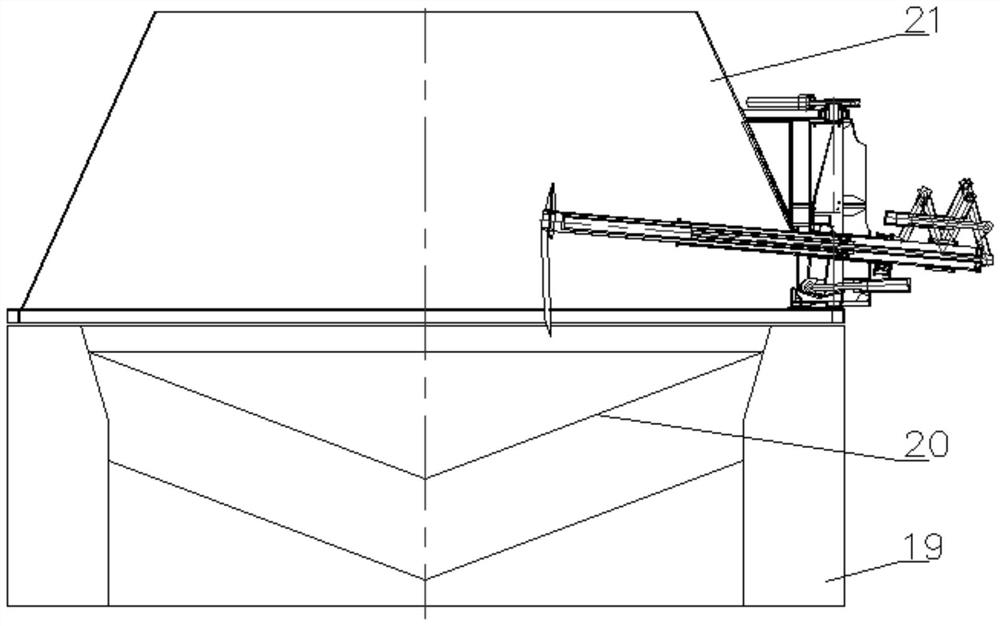

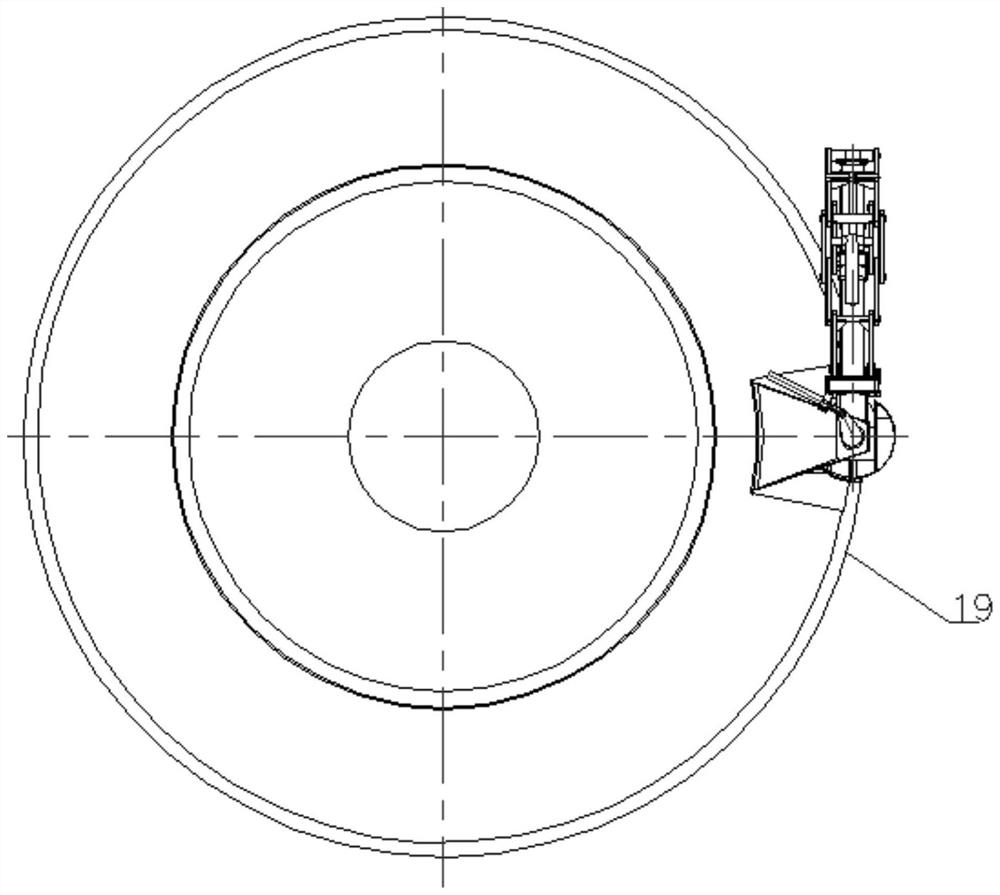

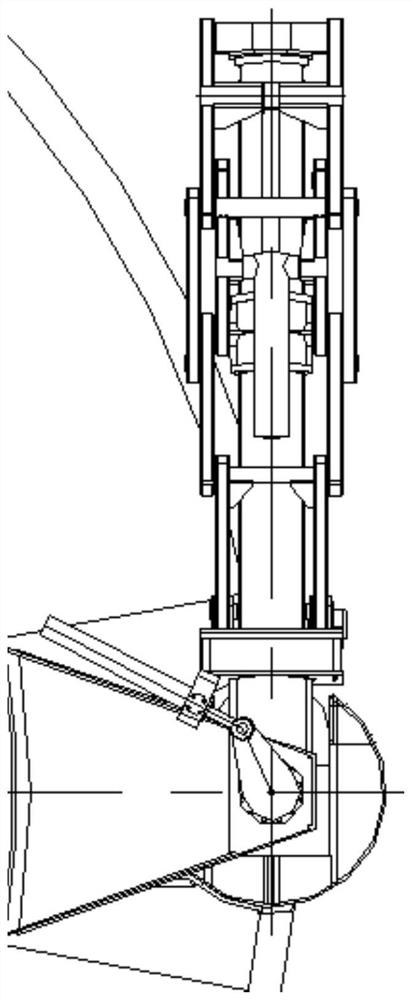

[0047] Such as figure 1 As shown in ~2(a) and Figure 2(b), the vertical sintering machine operating manipulator of this embodiment is installed outside the machine cover 21 of the sintering machine (sintering machine body 19), and is located outside the machine cover 21 when not in use. Standby state, this moment this manipulator and the space in the machine cover 21 are sealed and isolated; The inner and outer spaces of the cover 21 are isolated to ensure that the high-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com