Patents

Literature

63results about How to "Color green" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for planting organic vegetable okra

InactiveCN103931377AImprove securityEnsure safetyPlant protectionSeed coating/dressingNatural sourceSeed treatment

The invention discloses a method for planting organic vegetable okra. The method mainly comprises the steps of seed processing, soil preparation and fertilization, seedling transplantation, field management and harvesting. During the middle term of the okra, intertillage and earthing up need performing in time, and the soil is topdressed with organic fertilizers containing amino acid and humic acid. During insect control, natural source levorotation terpilenol and S-S rosin insecticides are utilized, diseased leaves, plant residues and weeds are processed through an organic method, and the whole process is free of pollution caused by chemicals. The organic planting model of the okra provides a firm technical foundation for promoting large-scale and standardized production of the organic vegetable okra planting industry.

Owner:GUIGANG HEAN HUIXING AGRI SCI & TECH

Mechanized method for processing flat green tea

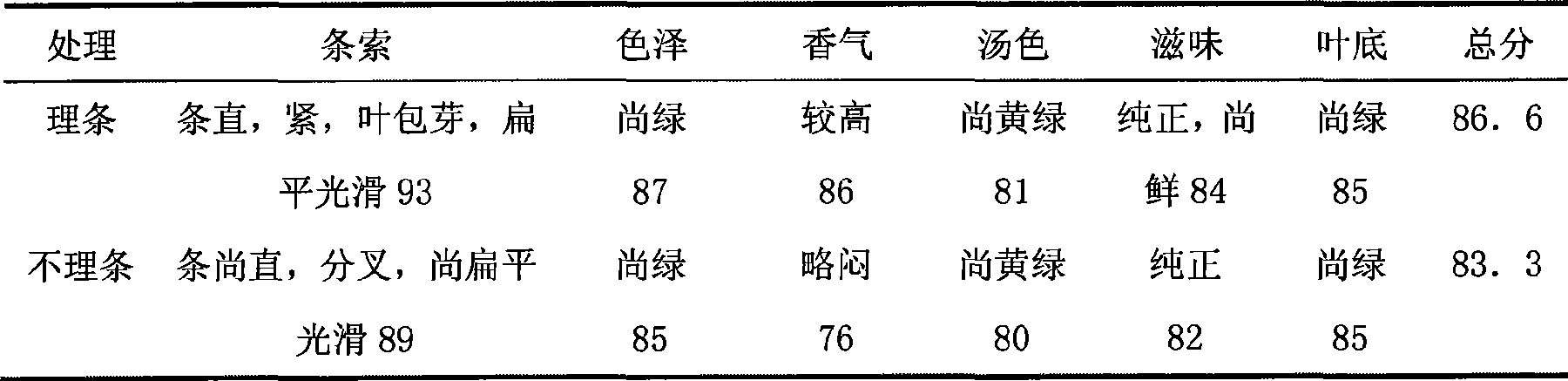

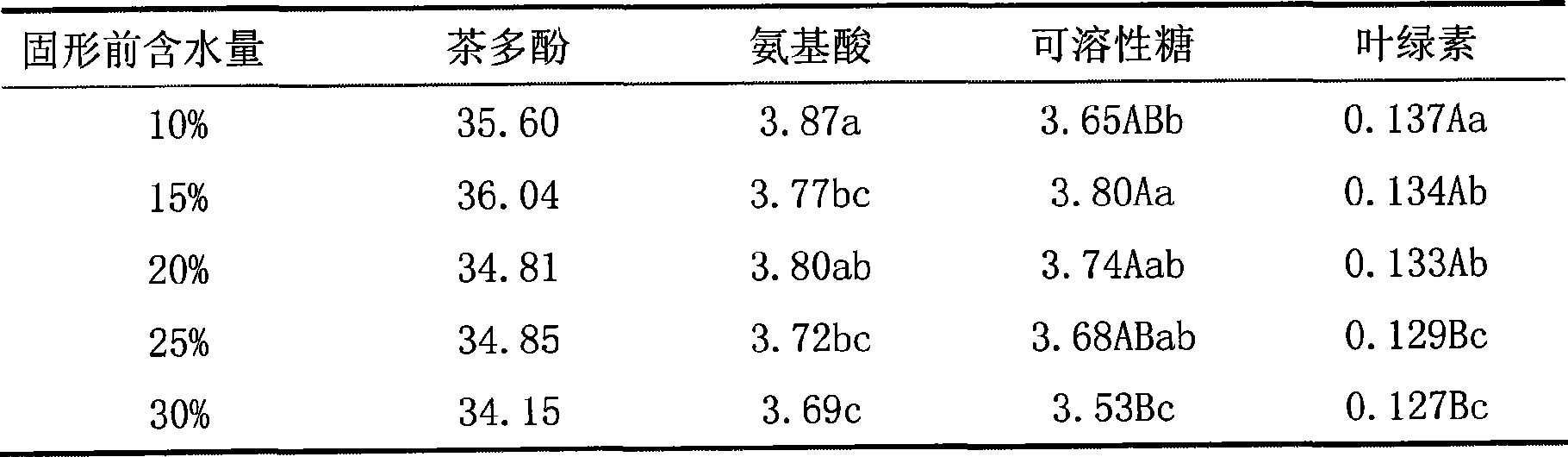

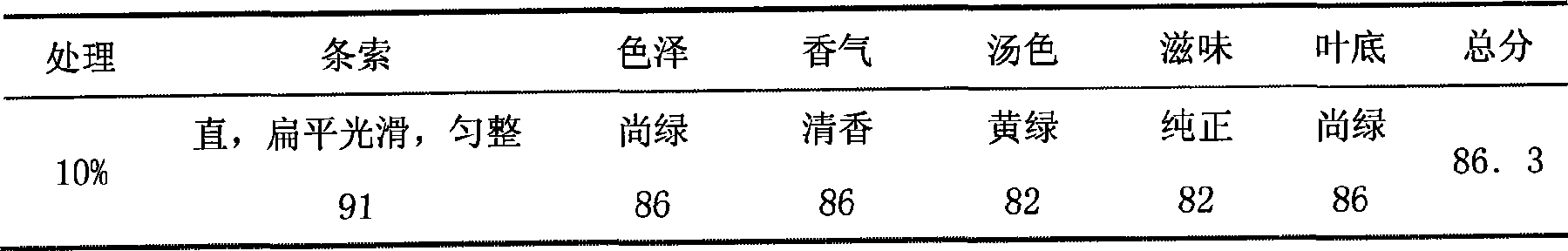

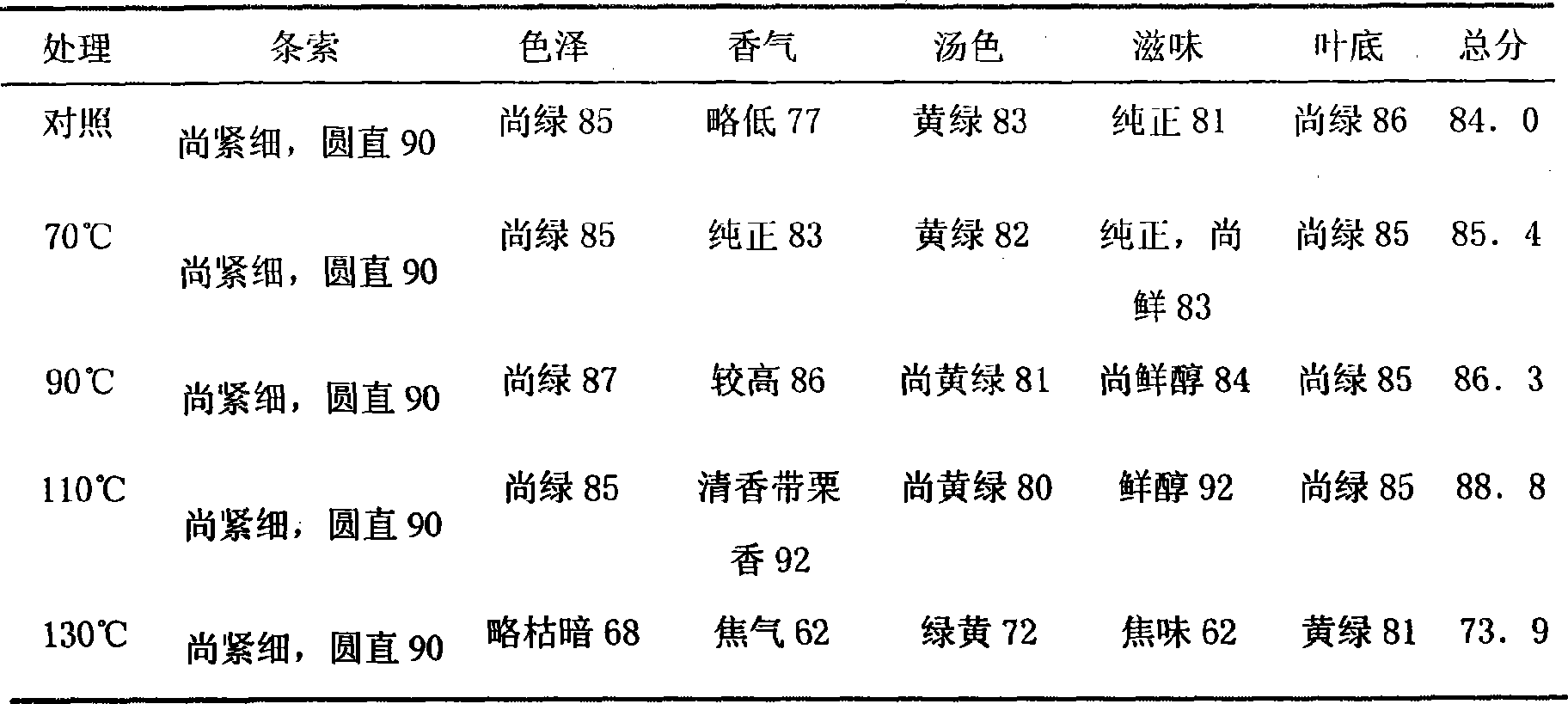

The invention belongs to the technical field of tea manufacture, in particular to a method for mechanically processing flat green tea. The method is characterized in that fresh green tea leaves are prepared into well-known tea with a flat shape through spreading, enzyme deactivating, sorting, pressing, solidifying, flavoring and other steps. The flat well-know tea has the characteristics of flat and smooth strips, no fragment, unpolished rice like color and luster, constant chestnut fragrance, green and bright color of liquor color, fresh and pure taste, tender, uniform, green and bright leaves and the like. The tea quality can completely reach the level of manually processing, and the method is applicable to mechanical processing production.

Owner:HUAZHONG AGRI UNIV

Mechanized method for processing styliform green tea

InactiveCN101366419AThe shape is tight, thin, round and straightBright green colorPre-extraction tea treatmentGreen teaEnzyme

The invention belongs to the technical field of tea manufacture, in particular to a method for mechanically processing acicular green tea. The method is characterized in that fresh green tea leaves are prepared into tea with acicular shape through spreading, enzyme deactivating, tightening, sorting, solidifying, drying, flavoring and other steps. The acicular well-known tea has the characteristics of tight, thin, round and straight strips, shape similar to pine straw, bright and green color and luster, silver tip exposedness, pure fragrance, fresh and rich taste, tender green and bright liquor color, tender and uniform leaves and the like. The tea quality can completely reach the level of manually processing, and the method is applicable to mechanical processing production.

Owner:HUAZHONG AGRI UNIV

Dendrobium candidum protocorm cooling beverage and preparation method thereof

InactiveCN105285642AColor greenAdd flavorFood ingredient as taste affecting agentNatural extract food ingredientsBiotechnologyAMERICAN GINSENG ROOT

The invention relates to a dendrobium candidum protocorm cooling beverage and a preparation method thereof, and belongs to the technical field of agricultural product processing. A dendrobium candidum protocorm cooling beverage formula comprises the following components in parts by weight: 5 to 10 parts of dendrobium candidum juice, 0.1 to 0.5 part of American ginseng extracting solution, 0.05 to 0.2 part of citric acid, 8 to 15 parts of rock sugar and 80 to 85 parts of water; a stabilizer formula comprises 0.05 percent to 0.2 percent of xanthan gum, 0.05 to 0.15 percent of CMC-Na and 0.05 percent to 0.2 percent of sodium alginate; specifically the finished product beverage is obtained by passing the inspection after performing cleaning, color protecting, juicing, filtering, blending, homogenizing, degassing, opening sealing, sterilizing and cooling on dendrobium candidum protocorm. The dendrobium candidum protocorm cooling beverage is dark green in color, has a unique green grass fragrance of dendrobium candidum, is sour and sweet, tasty, delicate and refreshing, and has better flavor, quality and stability.

Owner:刘楚玲

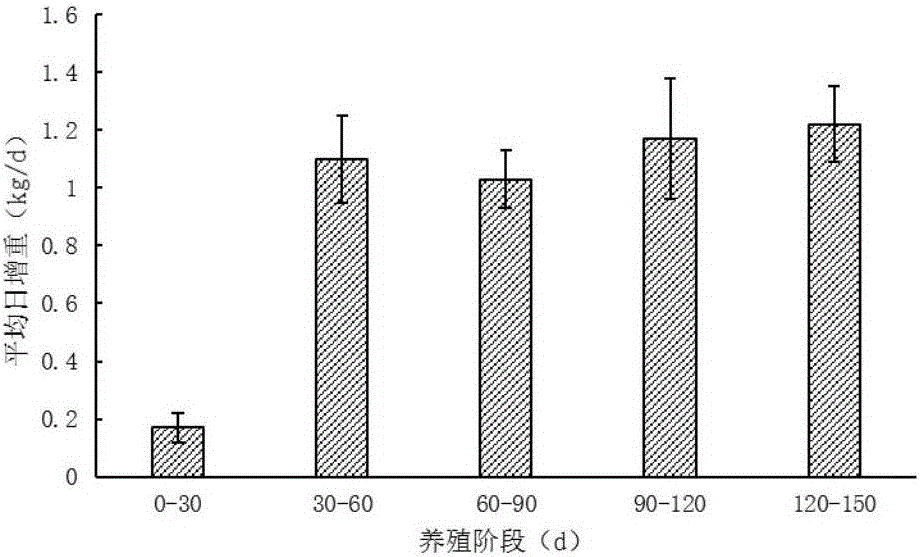

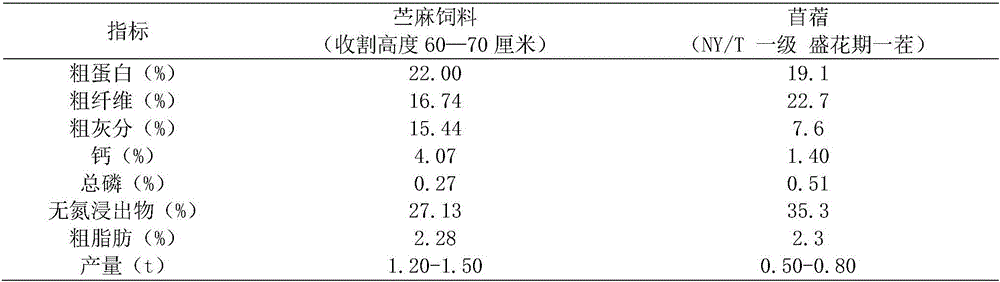

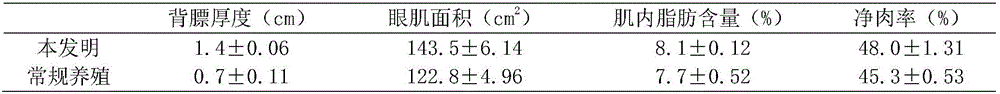

Method for preparing ramie ensilage feed

The invention discloses a method for preparing ramie ensilage feed. The method comprises steps of preparation of a fermentation liquid and preparation of ensilage feed. With the adoption of a suitable cultivation method, compound lactobacillus flora more beneficial to ensilage of a ramie by-product, namely, ensilage is cultivated within short time and is blended with crop straw such as wheat straw, rice straw, corn stalk and the like which are the easiest to obtain in a ramie production region to form ensilage feed with comprehensive and rich nutrients, efficient ensilage of fresh ramie plants is realized, the ensilage time is remarkably shortened, loss of nutrients is reduced, the feed quality is improved, and the method is applicable to yearly production and use of the ramie ensilage feed. The ramie ensilage feed prepared with the method can reduce consumption of concentrated feed by 25% and can effectively improve the beef quality without reducing the production performance of beef.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

Green bean tea

InactiveCN102948520AColor greenSimple manufacturing processPre-extraction tea treatmentSalt waterPericarpium citri reticulatae

The invention provides a green bean tea. The tea is prepared from baked green beans which are produced through peeling, cleaning, adding salt water for boiling and baking green soy beans, dried shredded carrot, pericarpium citri reticulatae, fructus perillae and tea leaves. The processed green bean tea has the advantages of green color, refreshing taste aroma, saltish taste, baked green bean taste, convenience and simplicity in production technology, economy, reasonable cost, safety and sanitation.

Owner:长兴乐田栝楼开发有限公司

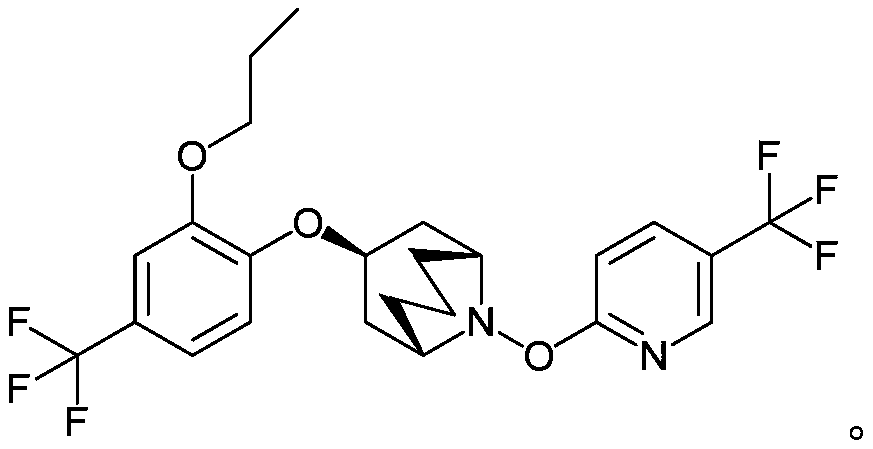

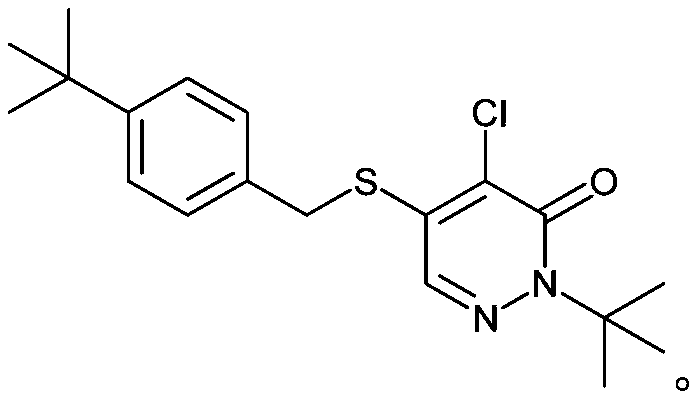

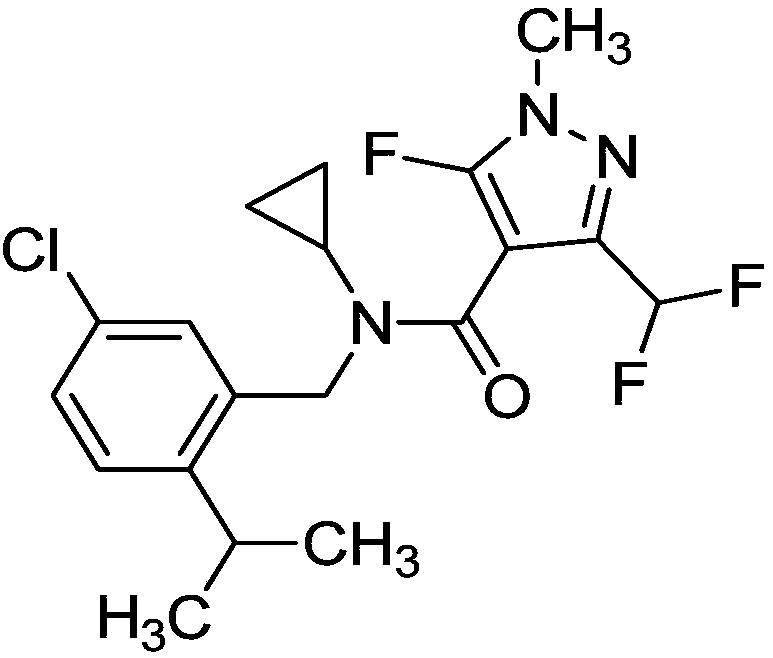

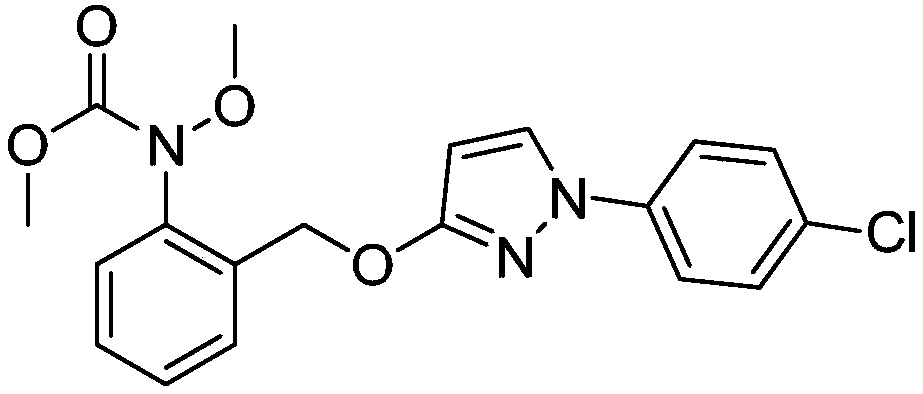

Acaricidal composition and preparation thereof, and application of acaricidal composition and preparation

InactiveCN109964940AToxicity and residual goodToxicity and Residue BalanceBiocideAnimal repellantsChemistryFenpropathrin

The invention belongs to the technical field of pesticides, and especially relates to an acaricidal composition and a preparation thereof, and an application of the acaricidal composition and the preparation. The effective components of the acaricidal composition comprise an active component A and an active component B; the effective component A is Acynonapyr, and the active component B is one ormore of pyridaben, etoxazole, spirodiclofen and fenpropathrin; a mass ratio of the active component A to the active component B is 80: 1 to 1:80, preferably 40:1 to 1:40, and more preferably 20:1 to 1:20; and the content sum of the active component A and the active component in the acaricidal composition is 5-80 wt%. The acaricidal composition or the preparation thereof has the advantages of effect enhancement, dosage reduction, prolongation of the lasting period, and delaying of the development of the pesticide resistance.

Owner:东莞市东阳光菌阳氢专利农药有限公司

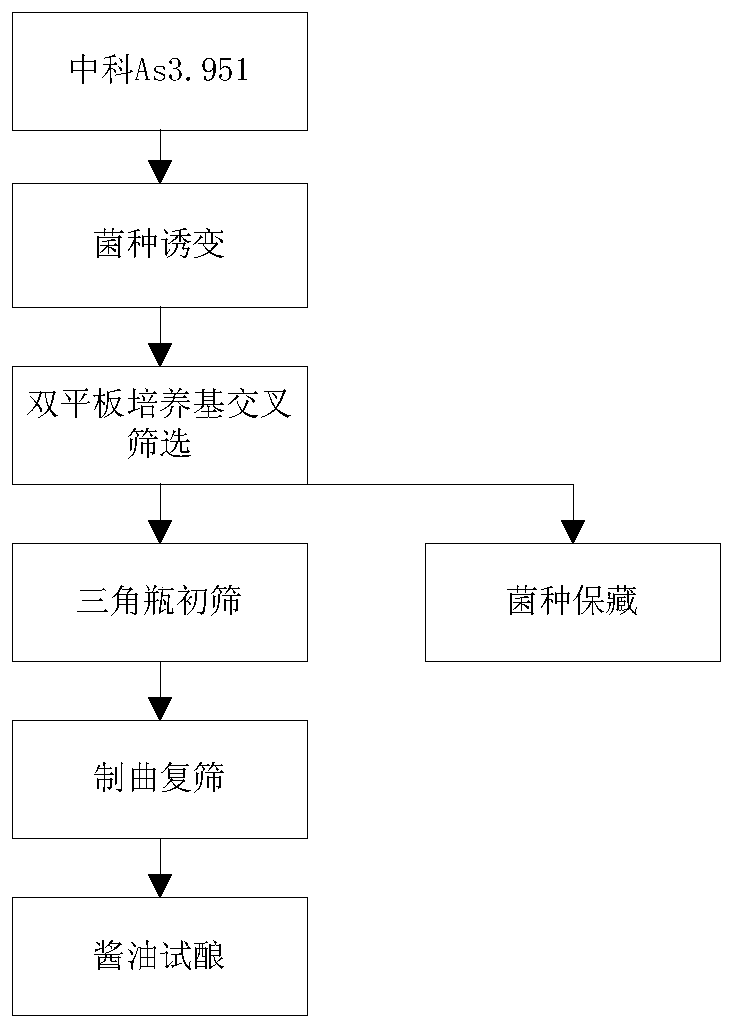

Aspergillus oryzae ZA184 and use thereof

The invention relates to the technical field of food processing and microbial fermentation, in particular to aspergillus oryzae ZA184 and use thereof in soy sauce brewing. The aspergillus oryzae ZA184can increase the pH of koji, enhance the activity of the koji enzymes (such as neutral protease, alkaline protease, leucine aminopeptidase and glutaminase), and improve the contents of amino nitrogen, total nitrogen and glutamic acid in soy sauce, so that the flavor and quality of the soy sauce is improved, the fermentation cycle can be significantly shortened, and the production efficiency is improved.

Owner:GUANGDONG HAITIAN INNOVATION TECH CO LTD +2

Method for making Shenxian bean curd by using dry premna puberula leaves

The invention discloses a method for making Shenxian bean curd by using dry premna puberula leaves. The method comprises the following steps of: picking the leaves at a vigorous premna puberula growth stage, and drying and storing the leaves for perennial production of the Shenxian bean curd; and when the Shenxian bean curd is made, mixing dry premna puberula leaf powder and drinking water with the pH value of 5.0 in a weight ratio of 1: (50-60), preserving the heat for 45 to 60 minutes at the temperature of between 65 and 75 DEG C, filtering, adding a proper amount of saturated lime water into the filtrate, standing, gelling, and thus obtaining the Shenxian bean curd. The method can meet the requirement for perennially producing the Shenxian bean curd; and the Shenxian bean curd made by the method is a good heat clearing and summer heat relieving product, which has high nutrient and health-care value and delicious taste and is purely natural.

Owner:GUIZHOU UNIV

Folium Artemisiae argyi scented tea manufacturing method

The invention discloses a Folium Artemisiae argyi scented tea manufacturing method. Folium Artemisiae argyi scented tea is prepared from Folium Artemisiae argyi and mugwort flowers by steps of picking, drying in the shade, removing herbaceous taste, removing moisture, roasting the Folium Artemisiae argyi, rolling and drying. The Folium Artemisiae argyi scented tea prepared according to the method keeps intact form and color of the Folium Artemisiae argyi, tea water of the Folium Artemisiae argyi scented tea is fresh green in color and rich in faint scent of the Folium Artemisiae argyi and light fragrance of the mugwort flowers, and the Folium Artemisiae argyi scented tea gives full play to nutrition and healthcare functions of the Folium Artemisiae argyi.

Owner:NANYANG BAICAOTANG NATURAL WORMWOOD PROD

Method for preparing high gamma-aminobutyric acid instant tea

ActiveCN103766531ASmall amount of boiling waterEmission reductionPre-extraction tea treatmentTea extractionFreeze-dryingReverse osmosis

The invention discloses a method for preparing high gamma-aminobutyric acid instant tea. The method comprises the following steps: soaking fresh tea leaves into a 0.25% to 2.5% glutamic acid aqueous solution, the weight of which is one to four times that of the fresh tea leaves; performing anaerobic treatment on the tea leaves for 0.5 to 30 hours under the vacuum degree being -0.05mpa to -0.1mpa; taking out the tea leaves and putting the tea leaves into boiling water, the weight of which is one to four times that of the tea leaves, for 10 to 30 seconds; combining the tea leaves with the glutamic acid aqueous solution after being used for soaking the fresh tea leaves; crushing and homogenizing for 1 to 5 minutes; filtering with a filter screen being 200 meshes; performing high-speed centrifugation on a filtrate at 5000rpm to 7000rpm (Revolutions Per Minute); performing reverse osmosis concentration until the concentration is greater than or equal to 100g / L; then performing reduced pressure evaporation concentration until the concentration is greater than or equal to 300g / L; and performing spray drying or freezing drying until the water content is less than or equal to 5%, thereby obtaining the high gamma-aminobutyric acid instant tea in a shape of green powder. The content of gamma-aminobutyric acid in gamma-aminobutyric acid is between 20.5mg / g and 35.5mg / g.

Owner:ZHEJIANG UNIV

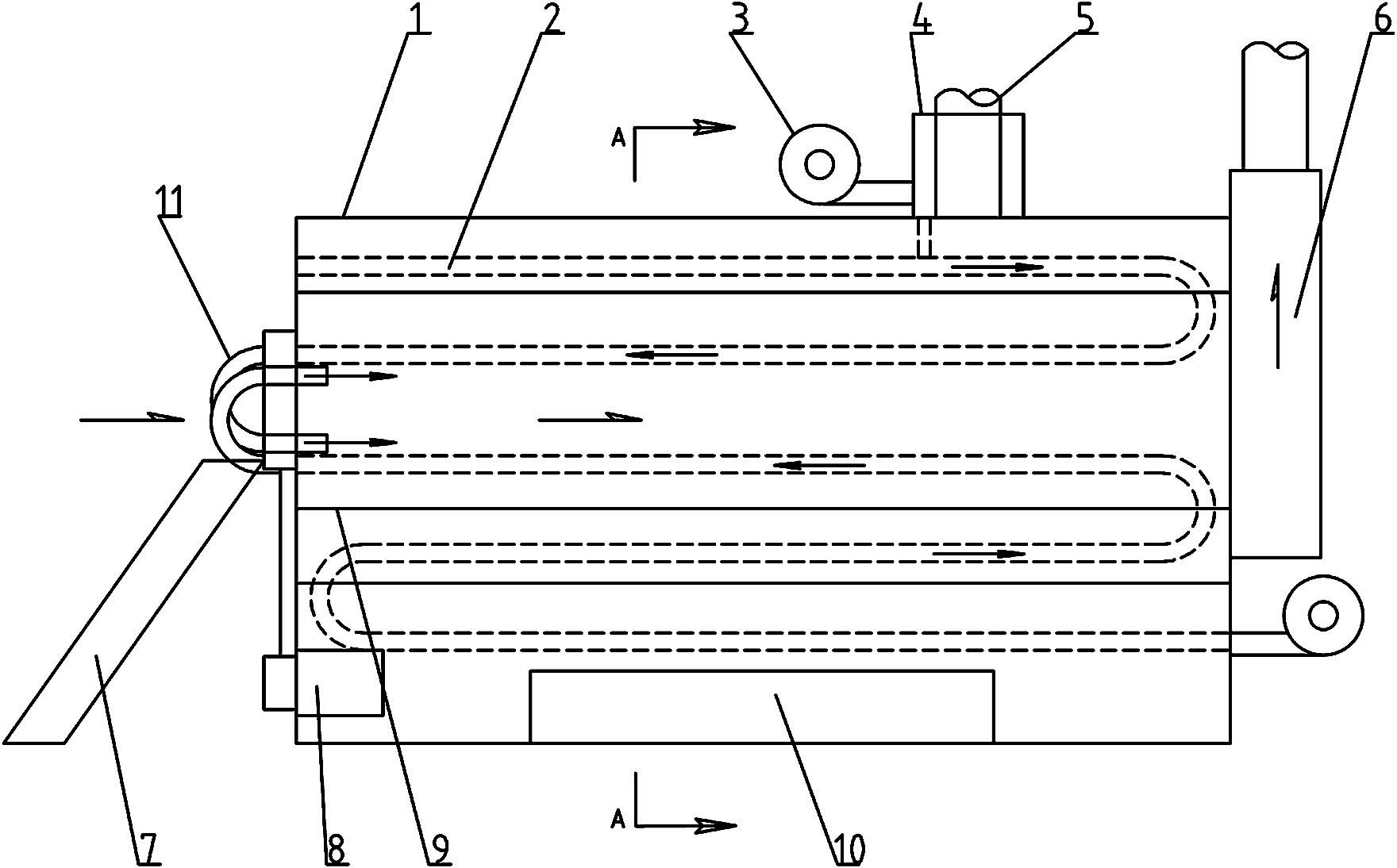

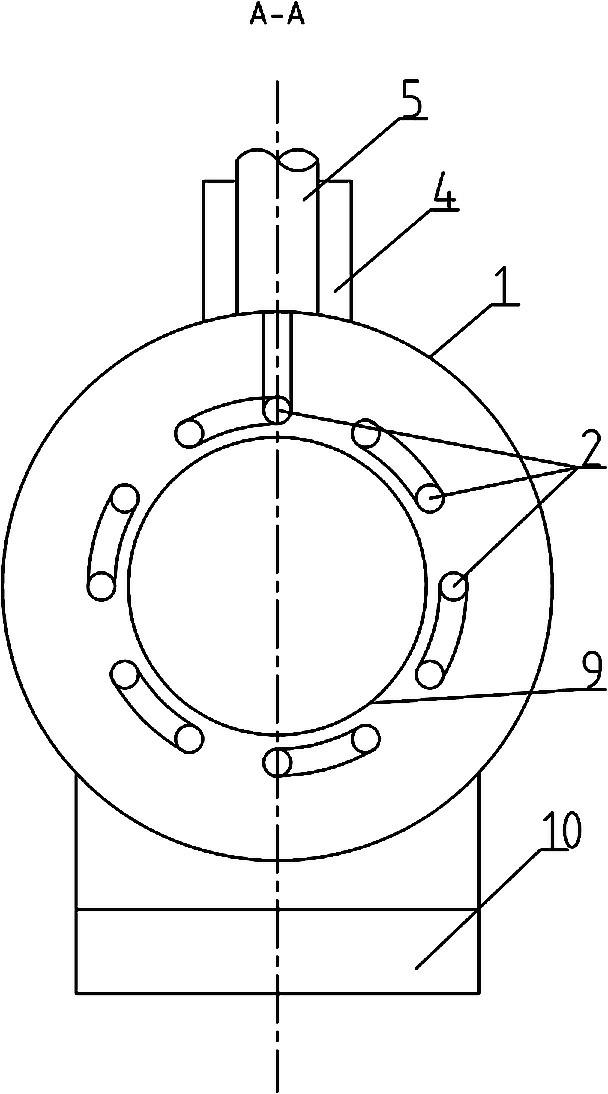

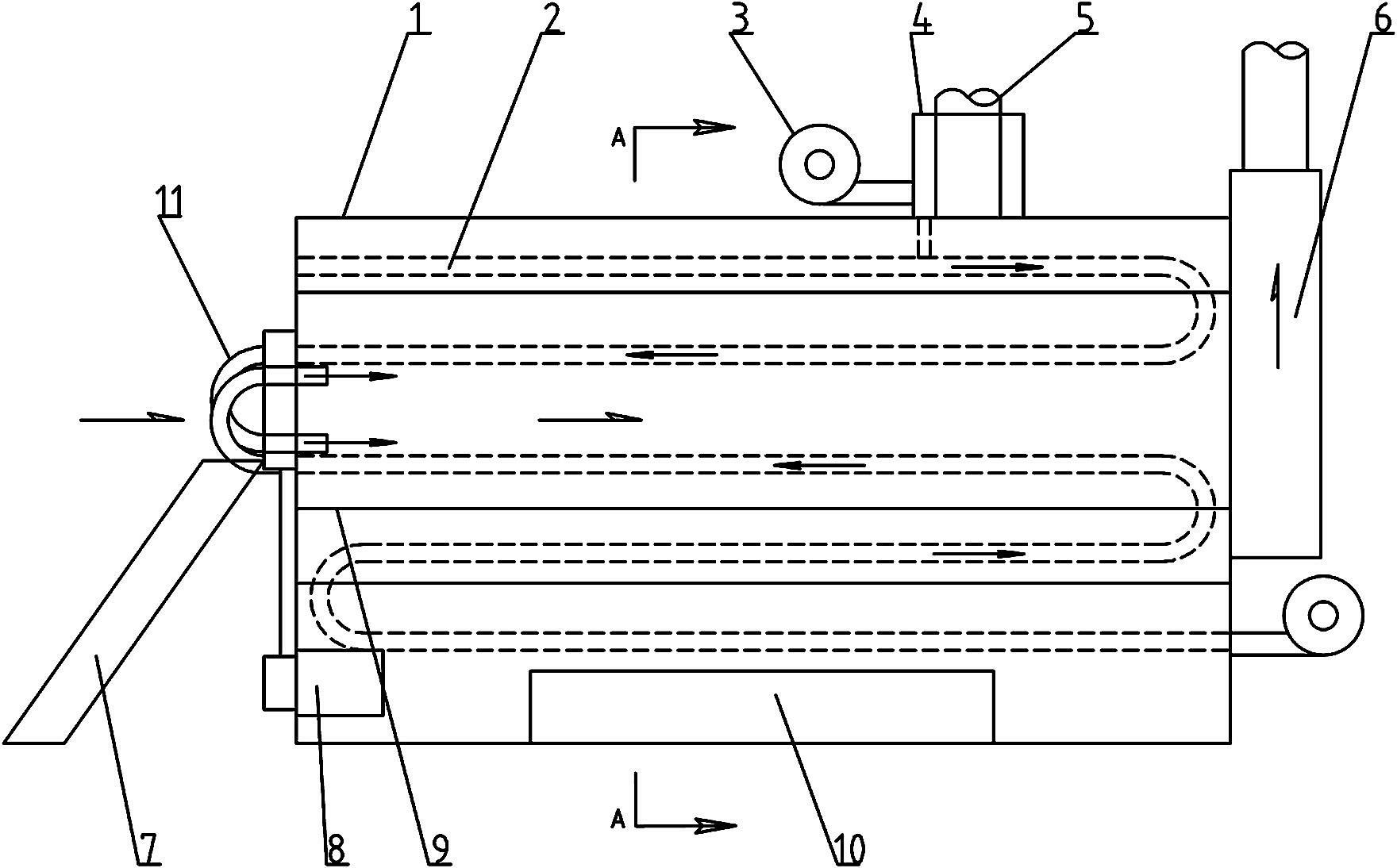

Hybrid hot-air enzyme deactivation machine

InactiveCN102308893ATake advantage ofColor greenPre-extraction tea treatmentHeating timeProcess engineering

The invention relates to a hybrid hot-air enzyme deactivation machine, comprising an insulation housing, a heating device inside the insulation housing, a cavity which is disposed between the insulation housing and a roller and is communicated with the heating device, several warm-air pipes arranged inside the cavity, with the outlets of the warm-air pipes located in the roller. By adding a heating device inside and with the cooperation of the warm-air pipes, the hybrid hot-air enzyme deactivation machine provided in the invention makes full use of fuel heat. Compared with the prior art, products are increased from 400kg to 1000kg with the same fuel. Meanwhile, because of fully utilized heat, processing efficiency is improved, i.e. the enzyme deactivation time is shortened. The efficiency is enhanced from the original 400kg / h to 1000kg / h. Besides, as the heating time is shortened, the color of tea is maintained dark green, and the product quality is improved.

Owner:WUFENG TIANCHI TEA MACHINERY +1

Processing method of black pepper

The invention discloses a method for processing green pepper, including the following steps: a. the green pepper is picked in 10-30 days before the pepper is ripe, and is washed with clean water; b. pretreatment is carried out: after being picked within 4-12 hours, the washed pepper is scalded with 80-100 DEG C of hot water for 6-30 minutes, then is taken out and quickly cooled, and the water is removed by dripping; c. the pretreated pepper is placed in time in an oven for drying, the drying temperature is kept between 40-75 DEG C, until the water content drops below 12 % by drying, the pepper is taken out for cooling. The pepper processed by the invention has perfect condition, green color, strong hot taste and pure fragrance; the method has high processing efficiency, microorganism infection is not likely to occur during processing, and the finished products processed has stable quality and is easy to store.

Owner:SPICE & BEVERAGE RES INST CHINESE ACAD OF TROPICAL AGRI SCI +1

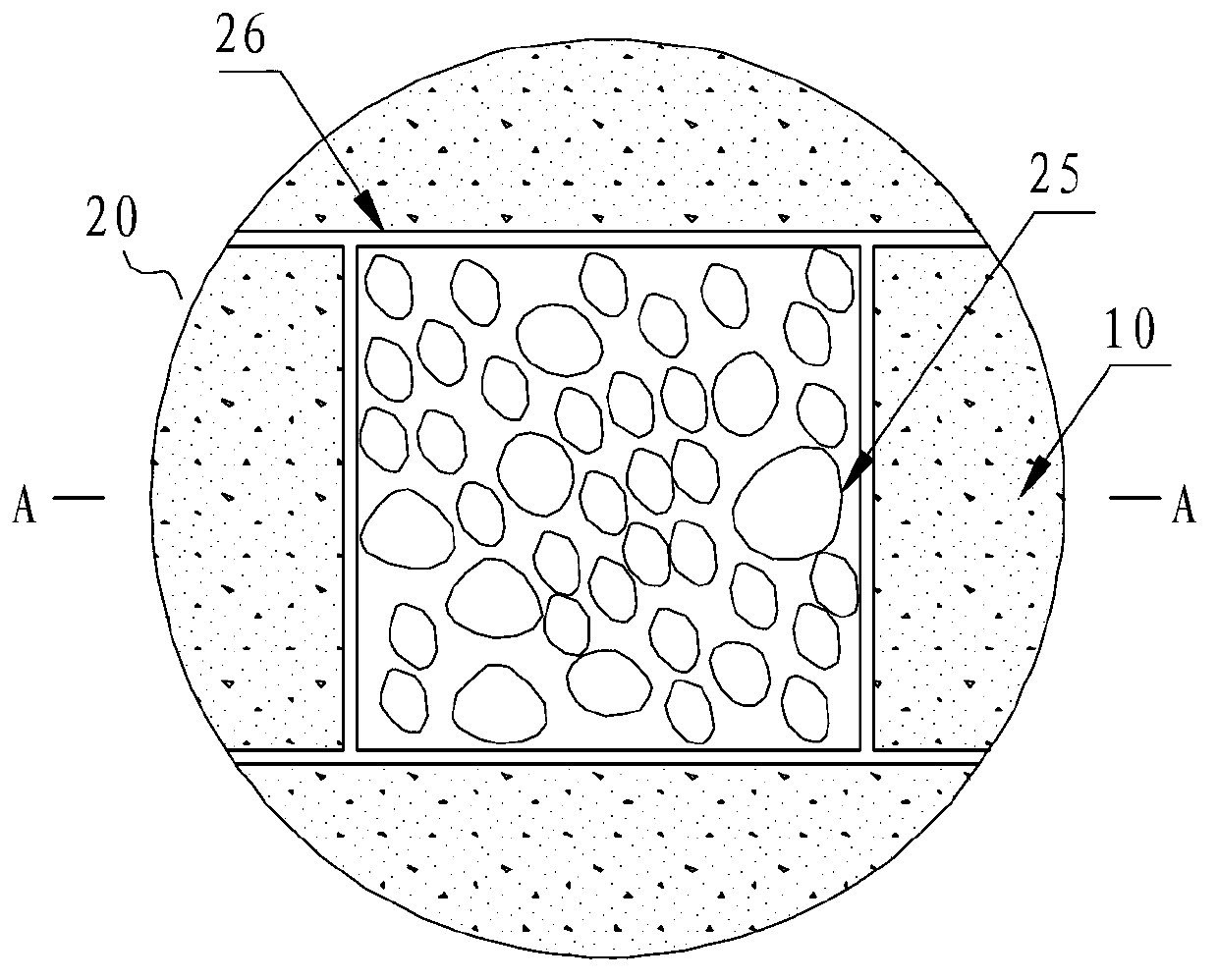

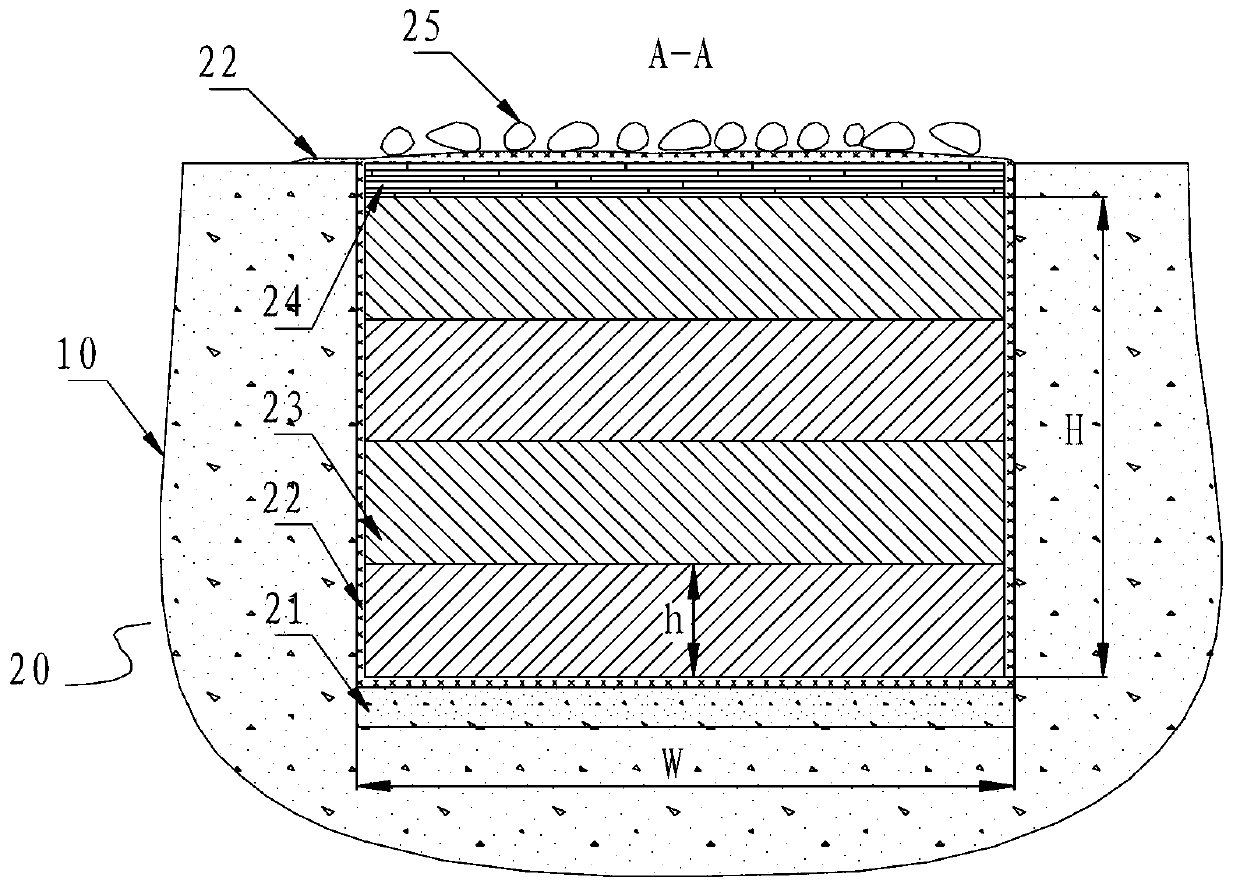

Silage method of whole corn stalks

InactiveCN103271252AEnhanced nutritional level and biological valueColor greenAnimal fodder preservationCarbon dioxideDomestic animal

The invention relates to a silage method of whole corn stalks. An underground silo is used for silaging the whole corn stalks. The silage method comprises the following steps of the treatment of bottom and periphery, preparation of a urea solution, pavement of corn stalks, compaction, corrosion resistance and taking. According to the silage method, spoilage bacteria do not easily enter the stalks, thereby being favorable for preservation of the stalks; urea is decomposed into ammonia and carbon dioxide, both of which can inhibit the activity of spoilage bacteria and have a corrosion resistance effect; and the decomposed ammonia provides non-protein nitrogen for microorganisms in the rumen of a ruminant to form microorganism proteins, thereby increasing the protein nutrition level and the biological value of the corn stalks. The silage whole corn stalks are dark green in color, are soft and juicy, are moderate in sweetness and sourness, and have good palatability and a higher operating value. The method is simple to operate and is easy to learn, and eases the labor shortage problem in autumn.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Processing method of green tea

InactiveCN108174935AIncrease productivityPrevent burnt leavesPre-extraction tea treatmentChemical reactionGreen tea

The invention discloses a processing method of green tea. The processing method of the green tea comprises the following steps of putting fresh tea leaves into a roller fixating machine, carrying outfirst fixation, carrying out second fixation, carrying out third fixation, carrying out primary baking, and carrying out drying; after each fixation in the roller fixating machine, vibration is carried out so as to remove hair, and air-cooling and air-selecting are performed so as to obtain dried tea which is neat, solid and beautiful. The invention has the following beneficial effects: the processing method of the green tea is capable of ensuring uniform distribution of water in the tea so as to enable full chemical reaction of substances in the tea; and thus, the prepared green tea has stable and uniform color, aroma and shape. The green tea prepared according to the processing method is dark green in color, neat in tea shape, and good in taste.

Owner:黔西南州华曦生态牧业有限公司

Liu'an guapian and flos osmanthi fragrantis tea and preparation method thereof

InactiveCN109497208ADistinct and long-lasting aromaColor greenPre-extraction tea treatmentTea flavoringTea leafOsmanthus

The invention discloses Liu'an guapian and flos osmanthi fragrantis tea and a preparation method thereof. The Liu'an guapian and flos osmanthi fragrantis tea is tea prepared by taking Summer and Autumn tea leaves of Liu'an guapian tea as a raw material and scenting flos osmanthi fragrantis. The preparation method comprises the following preparation steps: scenting, turning, baking, spreading for cooling and baking, and boxing: screening baked tea leaves after cooling, weighing the tea leaves, boxing and sealing for preservation. According to the Liu'an guapian and flos osmanthi fragrantis teaand the preparation method thereof, disclosed by the invention, the flos osmanthi fragrantis and the Liu'an guapian tea are scented together and are subjected to 360-degree baking until no frost is generated by adopting a machine, prepared dried flos osmanthi fragrantis tea is very green in color, the tea leaves are uniformly heated, the quality of the tea leaves is ensured, the fragrance of flososmanthi fragrantis is obvious and durable, the liquor color is yellow green, bright and durable, the liquor color is still bright after fourth brewing, and the taste is strong.

Owner:安徽省六安瓜片茶业股份有限公司

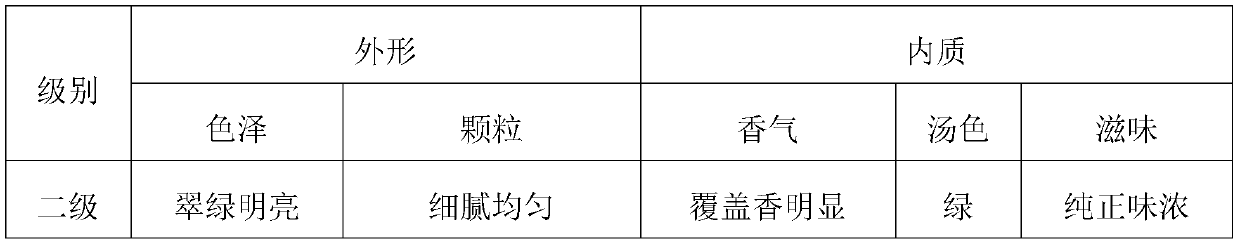

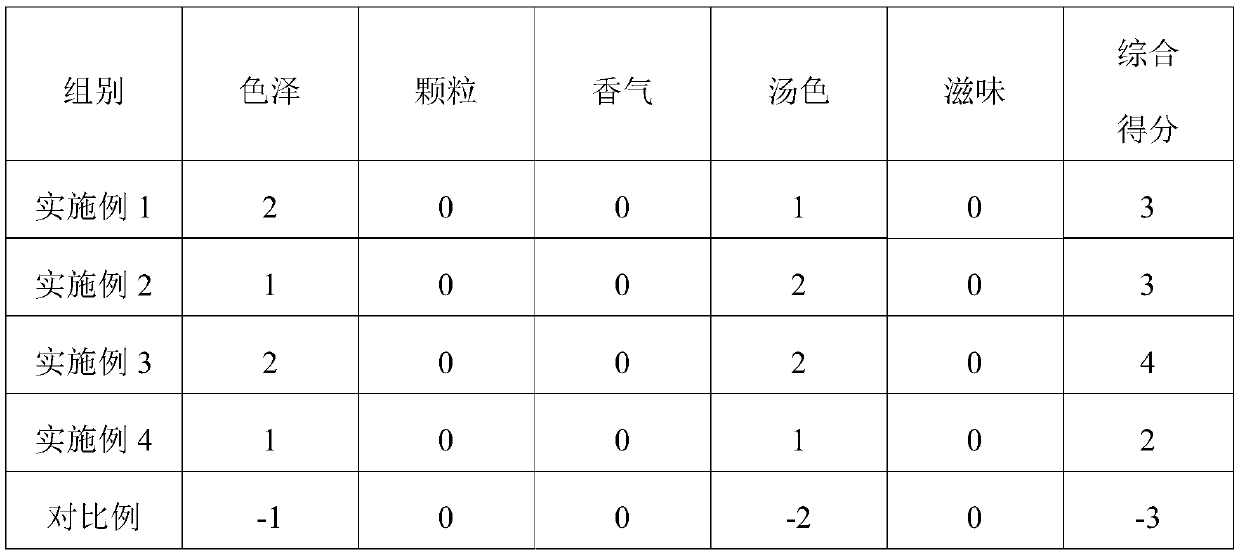

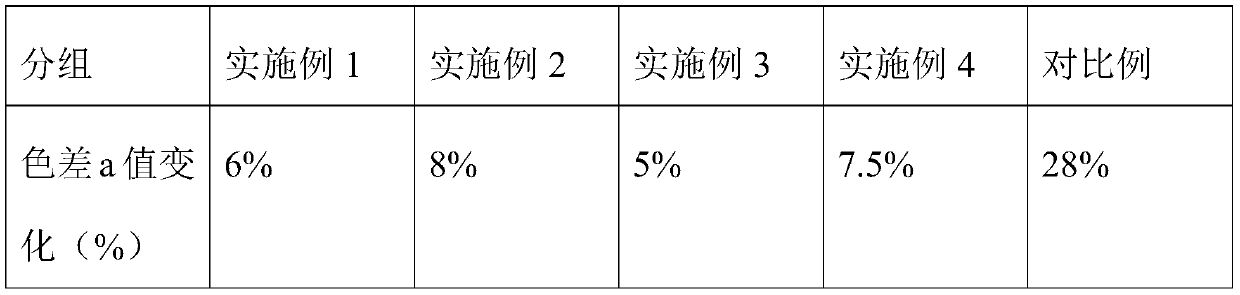

Tencha and processing technology thereof

ActiveCN110537594AColor greenHigh chlorophyll content retentionPre-extraction tea treatmentCooking & bakingEngineering

The invention provides Tencha and a processing technology thereof. The Tencha processing technology comprises a step of performing steam fixation on fresh leaves and a step of performing baking, wherein between the step of performing steam fixation on fresh leaves and the step of performing baking, a step of performing stirring treatment on fixation leaves obtained after performing steam fixationon fresh leaves in a container is also performed, and the interior wall of the container is manufactured of copper materials. According to the Tencha processing technology provided by the invention, the fixation leaves obtained after performing steam fixation on fresh leaves are subjected to the stirring treatment in the container of which the interior wall is manufactured of the copper materials,and then baking is performed, so that the content of reserved chlorophyll is higher, and the processed Tencha finished products are greener in color; and when the Tencha obtained by the method disclosed by the invention is processed into matcha, under the illumination treatment, the matcha processed from the Tencha is better in color stability than conventional matcha, and after 12 hours of the illumination treatment, the change rate of a color difference a value and a color difference b color is not higher than 8%.

Owner:浙江华仕达茶业股份有限公司

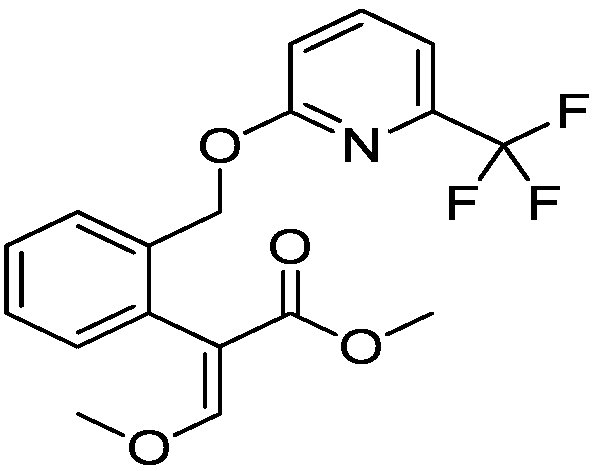

Sterilization composition containing Isoflucypram and methoxy acrylate bactericide

InactiveCN109169676AReduce the amount of applicationExpanded bactericidal spectrumBiocideFungicidesDiseaseBiology

The invention relates to a sterilization composition containing Isoflucypram and a methoxy acrylate bactericide, and a preparation and an application thereof. The methoxy acrylate bactericide is any one of pyraclostrobin, picoxystrobin, kresoxim-methyl and coumoxystrobin, wherein a mass ratio of the effective component Isoflucypram to the methoxy acrylate bactericide is (1-15):(15-1), and the total content of the Isoflucypram and the methoxy acrylate bactericide in the sterilization composition / preparation is from 1-80 mass%. The sterilization composition / preparation has a significant synergistic effect on the control of grape powdery mildew. The sterilization composition and the preparation are suitable for preventing and controlling powdery mildew, rust, glume blight, net blotch, downy mildew, rice blast and other diseases. The composition has the advantages of obvious synergistic effects of the active components, delaying of the pesticide resistance of pathogens, reduction of the pollution to the environment, and excellent practical values when applied to prevent and control crop diseases.

Owner:东莞市东阳光菌阳氢专利农药有限公司

Processing technology of Liuan guapian tea

The invention discloses a processing technology of Liuan guapian tea. The processing technology comprises the following steps of step 1, picking fresh leaves by a tea garden fresh leaf picking method,uniformly spreading the picked fresh leaves onto a green tea airing frame, spreading and withering in a constant-temperature green tea airing room at the temperature of 20 DEG C, and avoiding turnover of the tea leaves in the period. The processing technology has the advantages that the traditional method of picking the raw material and then breaking into pieces is changed into the tea garden fresh leaf picking method, so that the market time of the Liuan guapian tea is advanced, the output is increased, and the picking period is prolonged; by centrally spreading and withering in the constant-temperature green tea airing room at the temperature of 20 DEG C, the spreading is thorough, the fresh-keeping time of the fresh leaves can be prolonged, and the influence to the tea quality due to the deterioration of fresh leaves because of incomplete processing in the peak tea production period is avoided; compared with the traditional pot type enzyme deactivating method, the enzyme deactivating effect of a 80-type drum method is more thorough.

Owner:金寨县徽味香生态茶叶有限公司

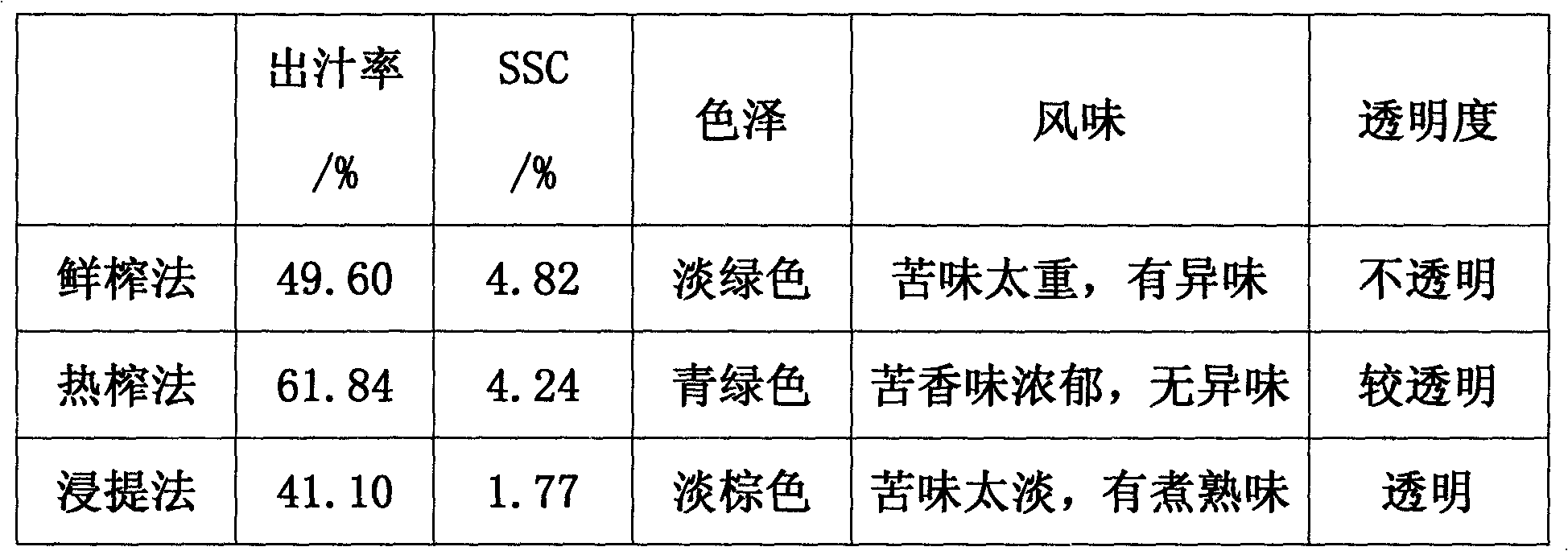

Extraction process of Ixeris denticulata

InactiveCN102871068AIncrease the juice yieldHigh soluble solids contentFood preparationSoluble solids

The invention relates to an extraction process of Ixeris denticulata. The extraction process provided in the invention is characterized by high juice yield and soluble solid content, and maintenance of a peculiar Ixeris denticulata flavour. The process employs a hot juicing method to extract an Ixeris denticulata juice, the technological steps include: carrying out material selecting and cleaning; conducting blanching at a temperature of 75-95DEG C for 1-5min, then immediately putting Ixeris denticulata into cold water for sudden cooling; and performing cutting, juicing, as well as filtering.

Owner:梁志雯

Sweat tea and its preparing process

InactiveCN1232175CMellow tasteAppearance and size are the samePre-extraction tea treatmentTea substituesSide effectGeneral Appearance

The present invention will disclose a kind of sweet tea and its production process. The production process of the sweet tea of the present invention is as follows: picking fresh leaves—drying green—cutting into sections—finishing—primary kneading—packing and kneading—stir frying— —Drying—refined to obtain finished sweet tea. Compared with the traditional tea production process, the sweet tea production process of the present invention adds a section cutting process, mainly because after the sweet tea is cut into sections, its section can be exposed to oxygen, which is beneficial to the oxidation and utilization of polyphenol oxidase in sweet tea leaves , making the taste of sweet tea more mellow, and the appearance size is the same as that of ordinary tea, and it is more suitable, neat and beautiful; and the sweet tea made by the sweet tea production process of the present invention has green color, beautiful appearance, and good taste. Various beneficial substances are also easier to brew out, and no additives are added in the production process, so there is no toxic or side effect. It is a pure organic green health care product that can be consumed for a long time.

Owner:陈显刚

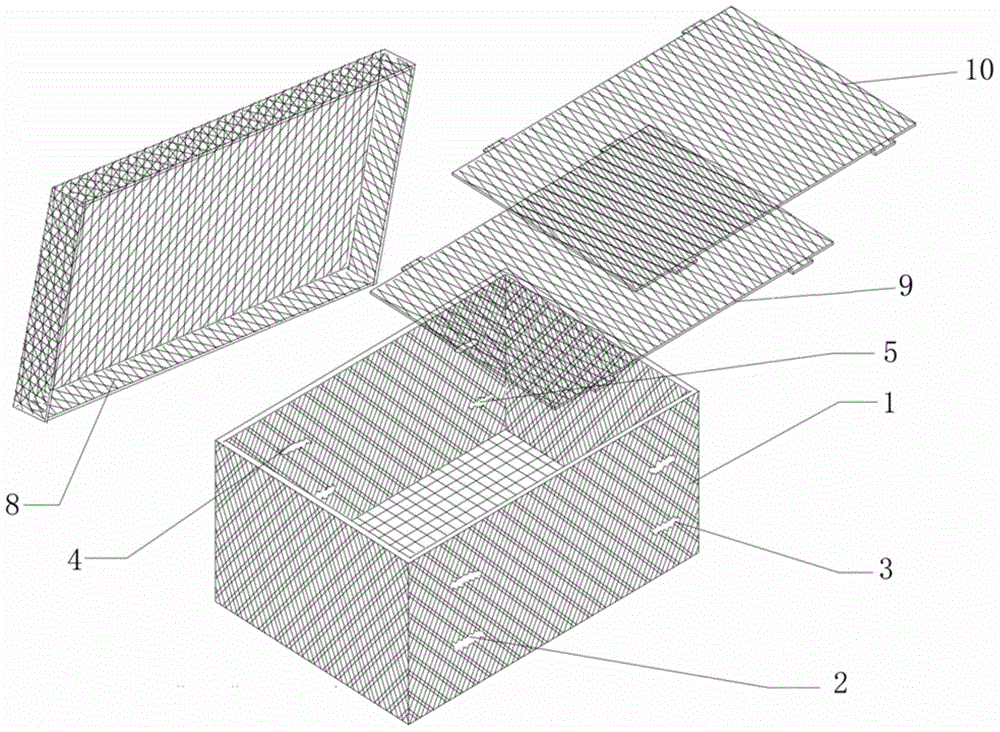

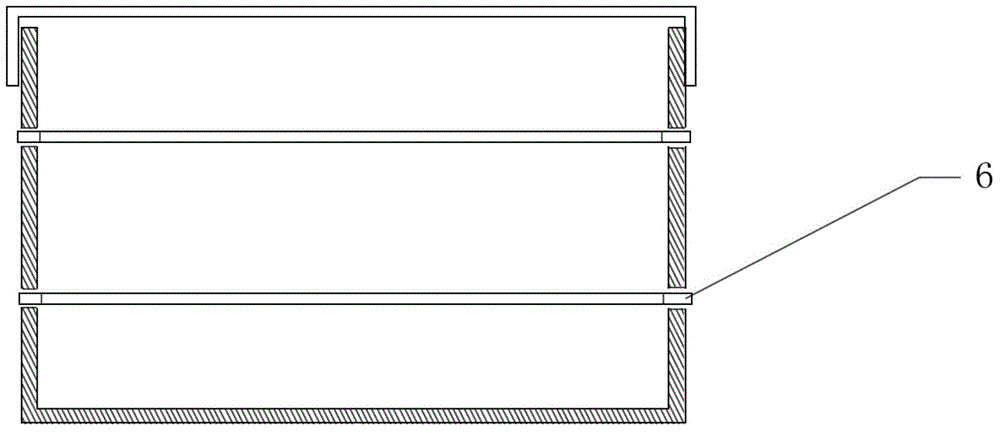

Fresh tea leaf transportation basket

InactiveCN104944004AReduce accumulationReduce leaf temperatureLiving organism packagingBio-packagingEngineeringTea leaf

The invention discloses a fresh tea leaf transportation basket. The fresh tea leaf transportation basket comprises a basket body and a basket cover. A partition net is arranged in the basket body and is parallel to the bottom face of the basket body. Due to the fact that the partition net is arranged, the stacking quantity of fresh tea leaves is reduced, pressure is reduced, it is guaranteed that the fresh tea leaves are in a loose and breathable state in the basket body, and the situation that the fresh tea leaves become red due to piling, heating, fermenting and mechanical damage during fresh tea leaf transportation is avoided. The whole transportation basket is woven by bamboo skin, ventilation is improved, breathability and freshness keeping are facilitated, peculiar smell is reduced, and the transportation basket is environmentally friendly, light, convenient to use, economical and practical. The actual use shows that the raw fresh tea leaves transported through the fresh tea leaf transportation basket do not become red, red stems do not occur, the tea leaves are green, fragrance diffuses far, the temperature of the fresh tea leaves is not high, and the tea leaves do not become bad. Meanwhile, the fresh tea leaf transportation basket is simple in structure, convenient to operate, environmentally friendly, capable of saving energy, suitable for transportation of different raw materials and different varieties of fresh tea leaves and very easy to apply and popularize.

Owner:SOUTH ASIAN TROPICAL AGRI SCI RES INST OF GUANGXI

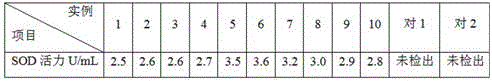

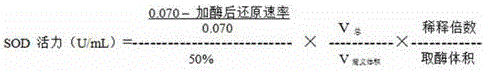

Cactus juice, preparation method thereof, health beverage and preparation method thereof

The invention relates to cactus juice, a preparation method thereof, a health beverage and a preparation method thereof. The preparation method of the cactus juice comprises the following steps: selecting cactuses, cleaning, and removing impurities; removing thorns and peels of the cactuses, and slicing the cactuses; adding water with the weight of 1.5-2 times of that of cactus slices into the cactus slices, and grinding, so as to obtain cactus slurry; filtering the cactus slurry, collecting filtrate, stirring for 30-60 minutes, standing at 0-4 DEG C for 3-4 hours, and collecting supernate, so as to obtain the cactus juice. The health beverage is prepared from the following raw materials by weight: 90g-120g of the cactus juice, 80g-110g of purslane juice, 15g-40g of a sallow thorn leaf extracting solution, 8g-15g of fructose and 0.02g-0.05g of ethyl maltol. The health beverage has fresh, cool, sweet and sour taste, faint scent and moistening and anti-aging effects, the color is uniform and is yellow green, and the SOD activity is high.

Owner:ZHONGZHOU UNIV

Production process of flat green tea

The invention discloses a production process of a flat green tea. The process includes the following steps that (1) picked fresh green tea leaves are spread for moisture removal until the fresh leavesare dehydrated, hard bud leaves become soft, the color is slightly dark green, the herbaceous flavor is reduced, and a light fragrance is emitted; (2) moderate fixation is carried out until the moisture content of the tea leaves is 60%-62%, the color of the leaves after fixation is changed into dark green from bright green, the leaves become soft and are clustered with slight stickiness when heldby hand, rawness is removed, a light fragrance is emitted, and the leaves are complete without burnt edges or burnt spots; (3) spreading is performed for cooling; (4) strip tidying is carried out until leaf strips are 40-50% dry and become flat and straight with a glossy green color; (5) spreading is performed for cooling; (6) shaping is carried out until the leaves are light green and become flat and straight with a fragrance; (7) spreading for cooling, stir-drying and fragrance enhancing are carried out. According to the process, by means of the technological innovations of properly prolonging the time of spreading for cooling and withering, increasing the fixation temperature, controlling drying for fragrance enhancement and the like, the high-quality tea with a green color, a strong fragrance and stable quality can be produced.

Owner:贵州鸿森茶业发展有限公司

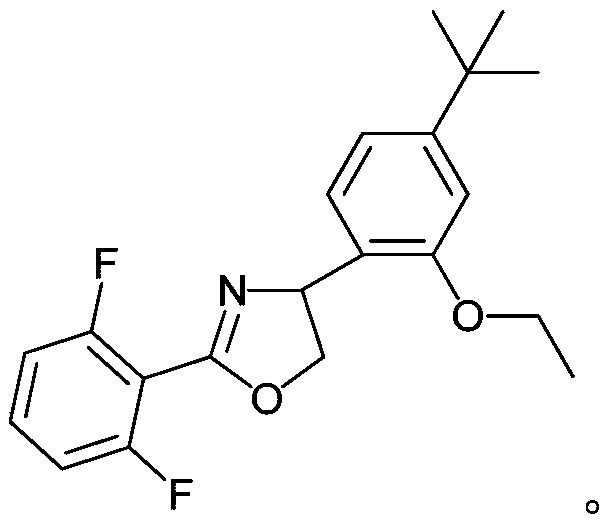

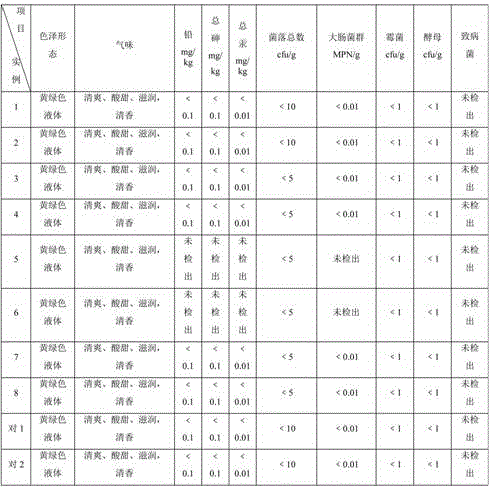

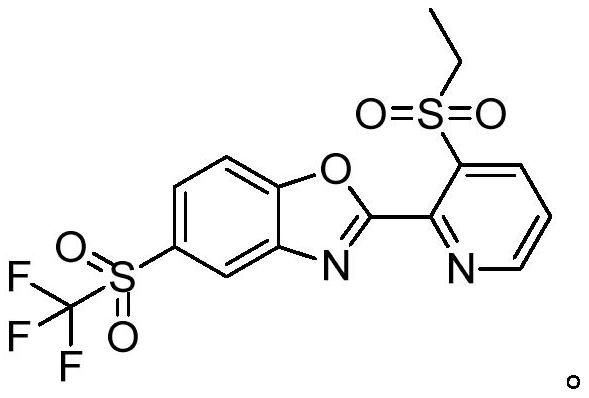

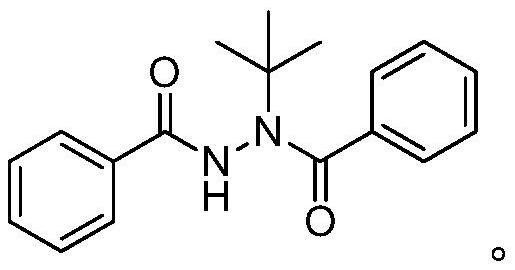

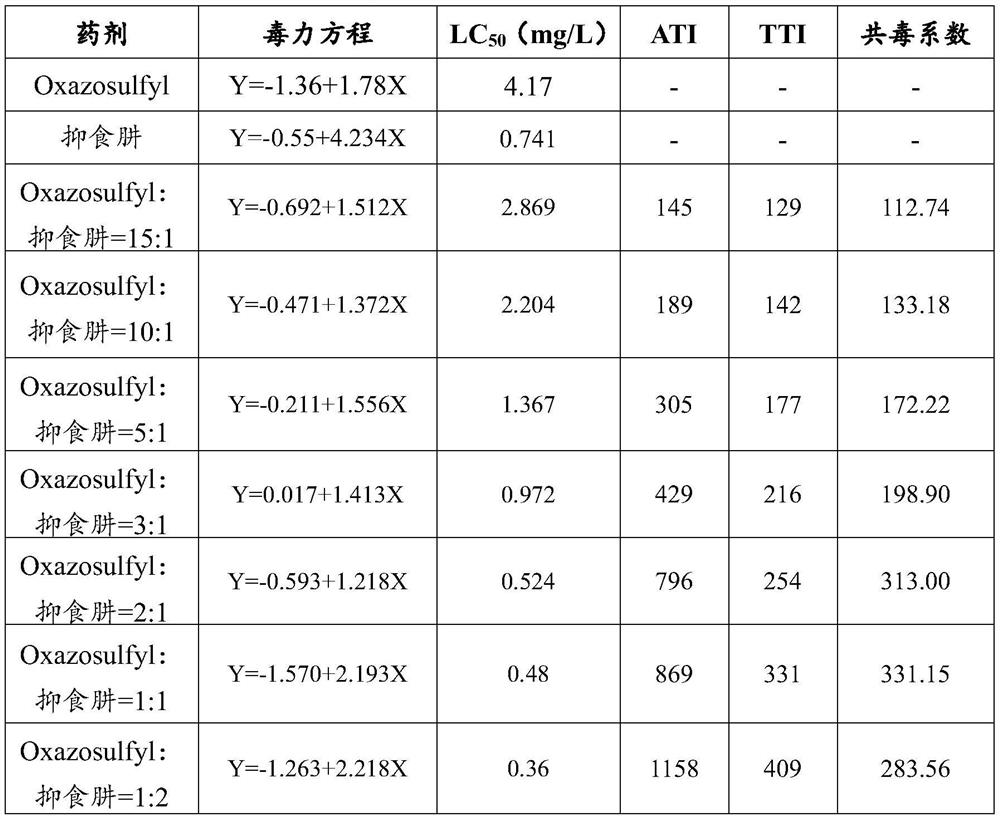

Insecticidal composition containing Oxazosulfuryl and RH-5849.

PendingCN112056318AReduce application rateGood application rateBiocideAnimal repellantsBenzoxazoleCnaphalocrocis

The invention relates to an insecticidal composition containing Oxazosulfuryl and RH-5849, specifically to an insecticidal composition containing 2-[3-(ethylsulfonyl)-2-pyridyl]-5-[(trifluoromethyl)sulfonyl]benzoxazole (Oxazosulfuryl) and RH-5849, a preparation and application of the insecticidal composition, wherein the mass ratio of effective components Oxazosulfuryl to RH-5849 is (1-10):(10-1),and the total mass content of the Oxazosulfuryl and RH-5849 in the insecticidal composition / preparation is 1-95% by mass. According to the insecticidal composition / preparation containing Oxazosulfuryl and RH-5849, the insecticidal spectrum is greatly broadened, and the insecticidal composition / preparation has a remarkable synergistic effect on prevention and treatment of cnaphalocrocis medinalisguenee and is suitable for prevention and treatment of pests and mites of rice, melons, fruits and vegetables.

Owner:东莞市东阳光菌阳氢专利农药有限公司

Rambutan-green tea beverage and preparation method thereof

InactiveCN103976083AGive full play to medicinal valueGreat tastePre-extraction tea treatmentFood preparationAuriculariaGreen tea

The invention discloses a rambutan-green tea beverage and a preparation method thereof. Every 200mL of the rambutan-green tea beverage is prepared from the following materials by weight: 20g-30g of fresh rambutan juice, 20g-25g of fresh green tea leaves, 5g-10g of honey, 1g-5g of sorbic acid, 1g-5g of citric acid, 1g-5g of auricularia auricular polysaccharides and the balance of water. The rambutan-green tea beverage disclosed by the invention is good in mouthfeel; and the preparation method is simple and easy to operate, low in cost, convenient for popularization, and easy for realizing standardized, normalized and industrial production.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Whole-plant corn stacking and storing method

PendingCN114223776AImprove digestibilitySolving the difficult problem of silage successAnimal feeding stuffAnimal fodder preservationAgricultural engineeringFermentation

The invention belongs to the technical field of whole-plant corn stacking and storage, and discloses a whole-plant corn stacking and storage method which comprises the following steps: harvesting whole-plant corn, crushing to obtain stacking and storage raw materials, and transporting the stacking and storage raw materials to a stacking and storage field within 6 hours; wherein the piled and stored raw materials comprise corn straws with the length of 0.9 to 1.9 cm; a hardened field with the thickness not smaller than 20 cm is selected in the stacking and storing field, multi-layer cellar pressing stacking and storing are conducted through cellar pressing machinery, a conical stacking and storing body is obtained, and the inclination degree of the inclined face of the conical stacking and storing body is 20-30 degrees; covering a sealing film on the conical stacking and storing body, and compacting the edge of the sealing film, so that the conical stacking and storing body is sealed and fermented; in conclusion, according to the method, full fermentation of piled raw materials is achieved through multi-layer pit pressing piled storage, the operation process is simple, reasonable, scientific and normative, and the corn silage prepared under the high-moisture condition has the advantages of being dark green in color, good in palatability, high in digestibility, small in nutrient substance loss and the like.

Owner:HEBEI NORTH UNIV

Closed production process of zanthoxylum armatum oil

PendingCN112126507AGood tasteExtended shelf lifeFatty-oils/fats productionProcess engineeringThermodynamics

The invention provides a closed production process of zanthoxylum armatum oil, and relates to the technical field of zanthoxylum armatum oil processing. The process comprises the following specific steps of: S1, selecting materials; S2, removing slag; S3, weighing; S4, closing: (a) controlling the temperature of a closed container to be 110-130 DEG C by using a heat conduction system; (b) furtherheating rapeseed oil (50-60 DEG C) for a circulating cooling system to 140-155 DEG C, and injecting the rapeseed oil into the closed container; (c) obtaining closed zanthoxylum armatum oil after the time lasts for 1-1.5 hours at the closing temperature of 110-130 DEG C; S5, cooling; S6, filtering; and S7, tailing treatment. By adopting the method disclosed by the invention, the yield of flavor substances and numb-taste substances of the zanthoxylum armatum can be greatly improved, and the zanthoxylum armatum oil which is proper in component proportion and can be stored is obtained.

Owner:HONGYA YAOMAZI FOOD

Production method of ultramicro green tea powder

InactiveCN111213733ASimple production methodColor greenPre-extraction tea treatmentProcess engineeringEpigallo-catechin gallate

The invention discloses a production method of ultramicro green tea powder. New fresh and tender tea leaves in the current year are used as a raw material. The method comprises the following steps: performing green leaf storing, fixation, cooling and drying, and separating leaves from tea stems by using a stem-leaf separator; and carrying out secondary drying, secondary stem-leaf separation, ball-milling crushing and mechanical grinding, and sieving ground tea powder to obtain a tea powder meeting the specification fineness. The tea powder disclosed by the invention is simple in production method, green and uniform in color and luster, fragrant in smell, small in fineness and free of metal components, and the obtained tea powder is used for making matcha products which are fresh in taste.

Owner:刘艳云

Sweet tea and production technology thereof

InactiveCN106804831AMellow tasteAppearance and size are the sameTea substituesCooking & bakingSide effect

The invention discloses sweet tea and a production technology thereof. The production technology of the sweet tea disclosed by the invention comprises the following steps of picking fresh leaves, cooling tea leaves, and performing segment cutting; performing fixation; performing first kneading; performing bundling; performing wrapping and twisting; performing frying to generate fragrance; performing baking; and performing refining so as to obtain finished products namely the sweet tea. Compared with a production technology of conventional tea leaves, the production technology of the sweet tea disclosed by the invention has the advantages that the segment cutting working procedure is additionally set, after segment cutting is performed on the sweet tea, fault surfaces can be in contact with oxygen, and the oxidation and utilization of polyphenols oxidase in sweet tea leaves are facilitated, so that the sweet tea is mellow in taste, the appearance and the size of the sweet tea are the same as those of ordinary tea leaves, and the sweet tea is proper, tidy and artistic; besides, the sweet tea made by the production technology of the sweet tea disclosed by the invention is green in color, artistic in shape and good in mouth feel and taste, and various substances beneficial to human bodies, of the sweet tea, are easy to brew to enter tea soup; and besides, no additives are added in the production technology, so that the sweet tea does not have toxic and side effects and is purely organic green health-care product which can be drunk for a long term.

Owner:姜蕾

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com