Hybrid hot-air enzyme deactivation machine

A hot-air greening machine and a hybrid technology, applied in the field of tea machinery, can solve the problems of low heat utilization efficiency, low processing efficiency, fuel waste, etc., and achieve the effects of maintaining green tea color, improving processing efficiency and improving product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

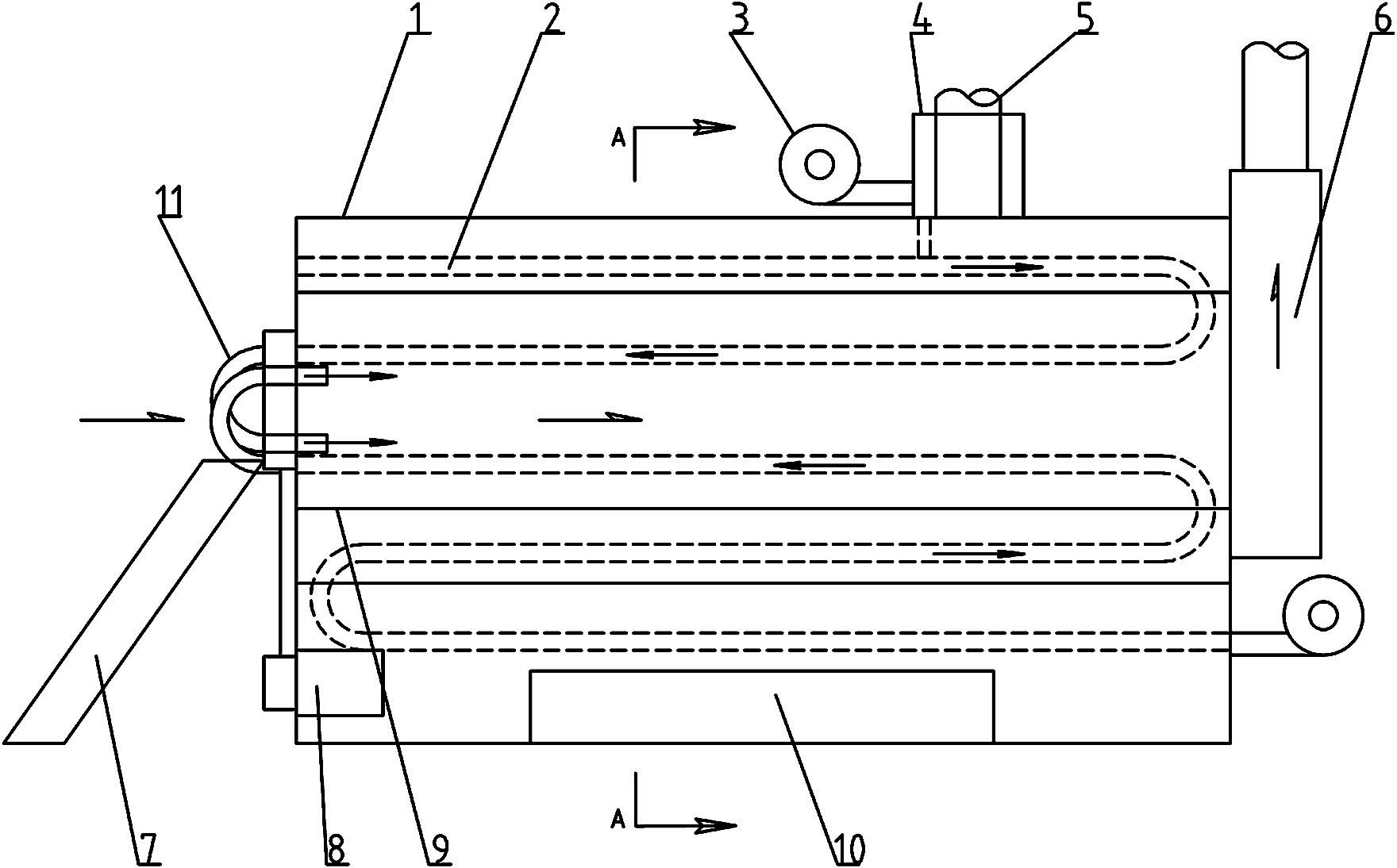

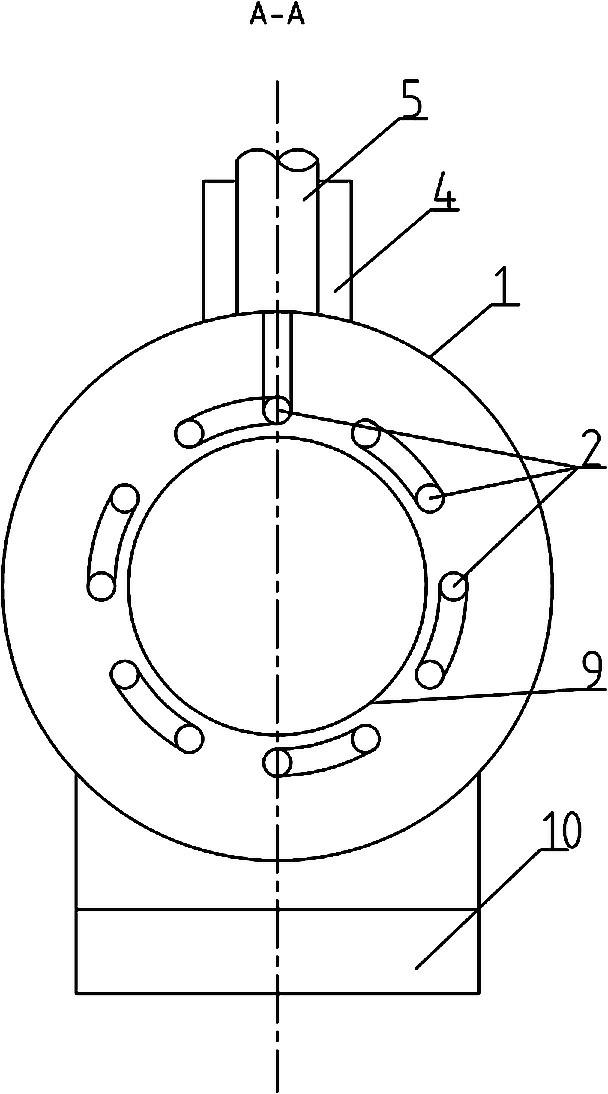

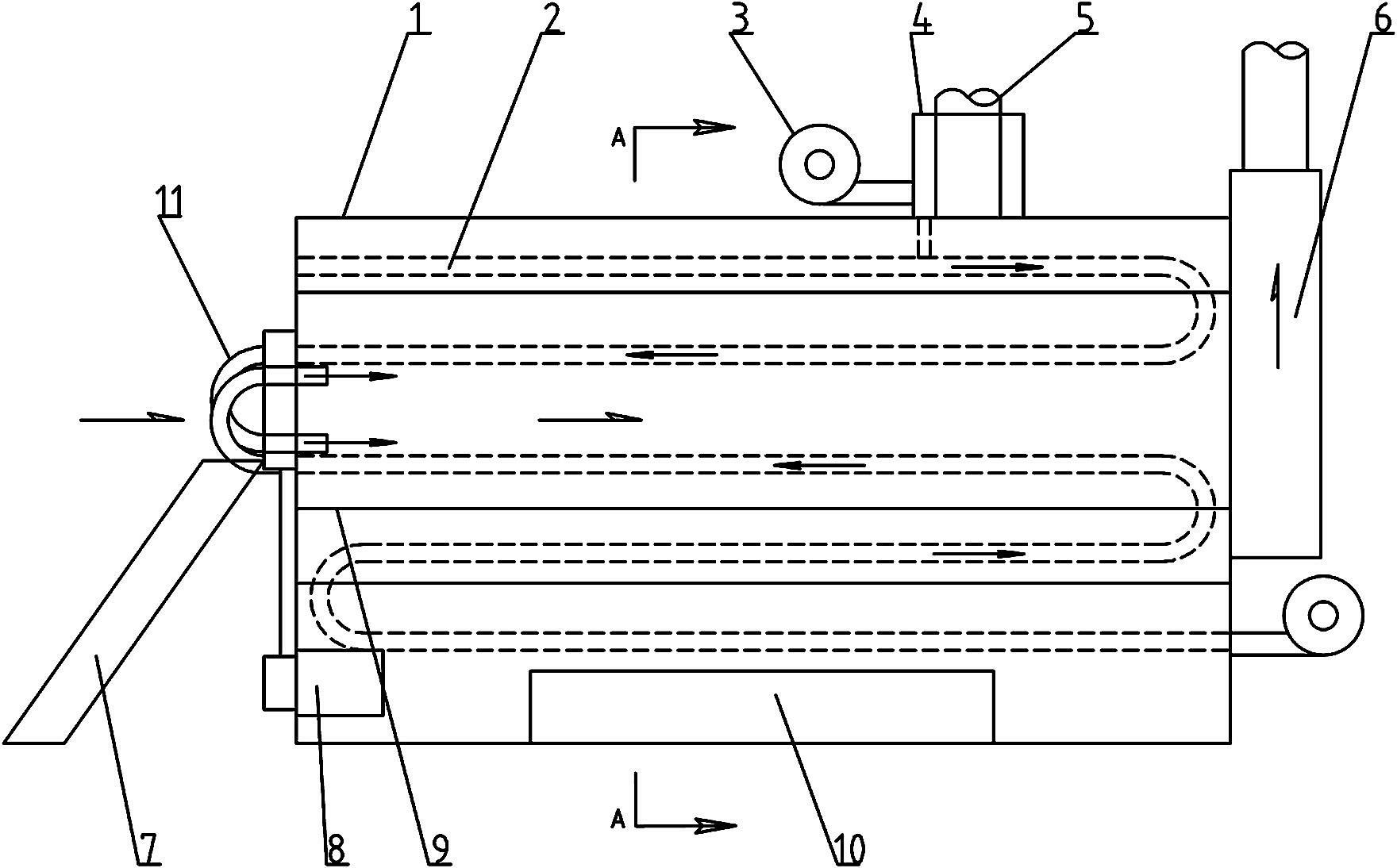

[0016] Such as figure 1 Among them, a hybrid hot air cleaning machine includes a thermal insulation shell 1, a drum 9 is installed in the thermal insulation shell 1, and a motor 8 drives the drum 9 to rotate, and a plurality of guide vanes and spiral blades are arranged in the drum 9. With the rotation of the drum 9, the helical blades push the tea leaves from the inlet to the outlet of the drum 9, and the guide vanes prevent the tea leaves from falling from the outlet when the drum 9 rotates. A heating device 10 is arranged inside the heat preservation shell 1 , and during the rotation of the drum 9 , the heating device 10 realizes frying green leaves in the drum 9 . A cavity is formed between the thermal insulation shell 1 and the drum 9 , and the cavity communicates with the heating device 10 , and a plurality of hot air pipes 2 are arranged in the cavity, and the outlets 11 of the hot air pipes are located in the drum 9 . In this example, the heating device is a firewood ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com