Silage method of whole corn stalks

A corn stalk and silage technology, which is applied to the preservation method, application, and animal feed of animal feed materials, can solve the problems of lactic acid bacteria fermentation conditions, corn stalk silage rot, mildew, and difficult compaction of corn stalks, etc., to achieve Effects of improving nutritional level and biological value, good palatability, and green color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

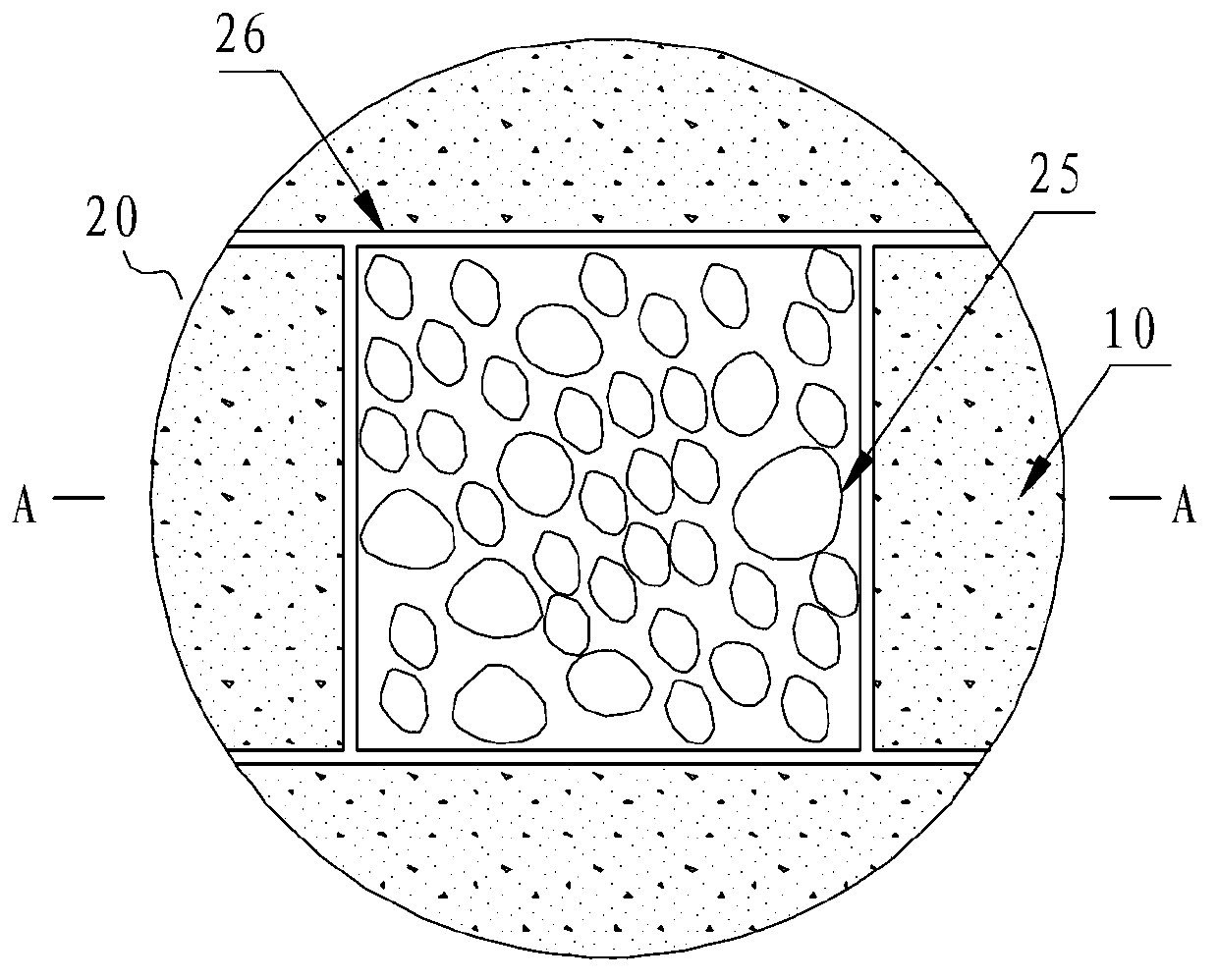

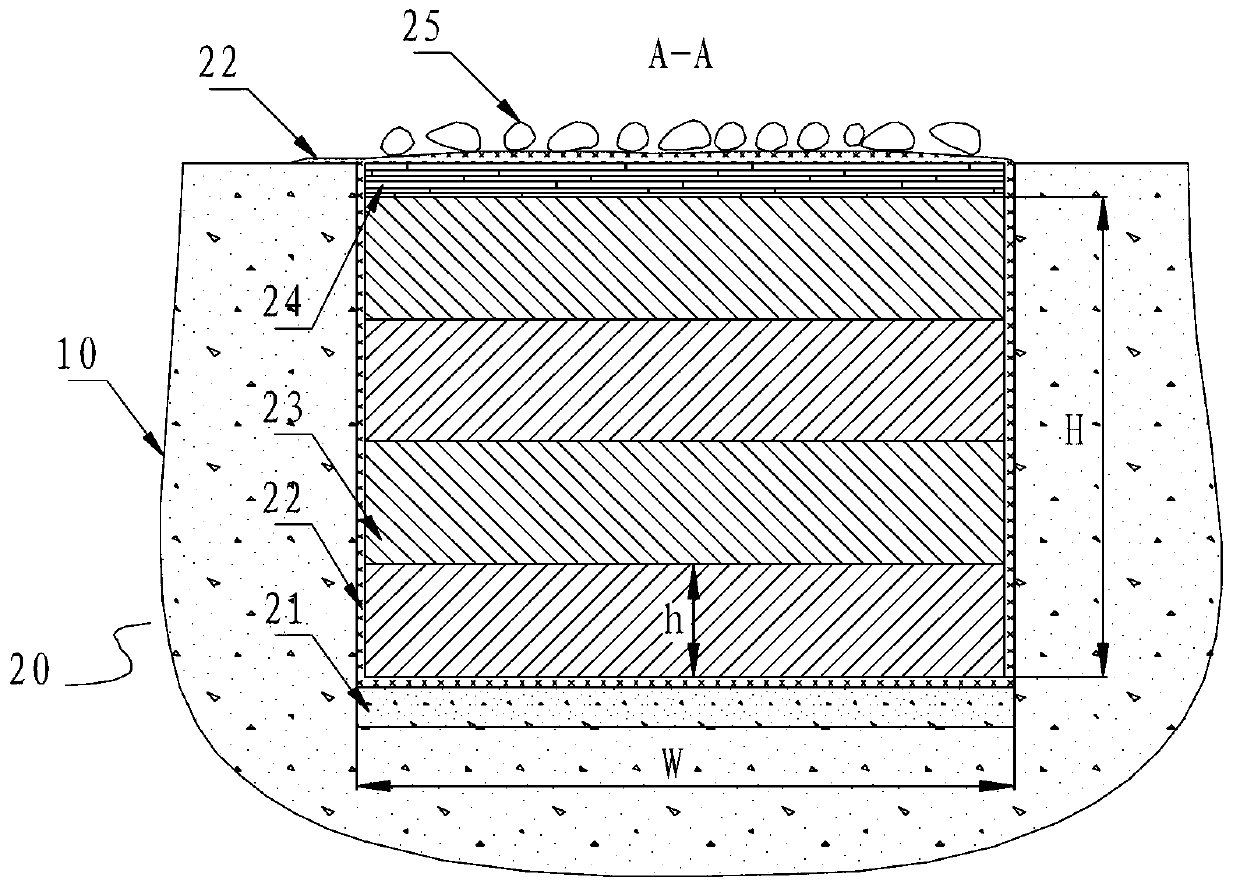

[0031] Such as figure 1 As shown, it is a schematic view of the structure of a silo according to the embodiment of the present invention when viewed from above, figure 2 for figure 1 Middle A-A view. The silo 20 of the present invention is arranged below the ground 10 . The silo cellar 20 is high and dry, and the groundwater table is low and digs a rectangle, or is piled up by concrete, and its surroundings are smooth, airtight, and watertight. After the silo 20 was completed, the whole corn stalks were ensiled according to the following steps:

[0032] Step 1: bottom and surrounding treatment;

[0033] Spread some grass powder 21 at the bottom of the silo pit 20 to facilitate the fermentation of the whole corn stalk and exhaust during silage, then spread the wide plastic film 22 on the bottom and four walls of the silo pit 20, the plastic film 22 adopts Non-toxic polyethylene plastic film with a thickness of 0.1mm to 0.2mm.

[0034] Step 2: configure urea solution;

...

Embodiment 2

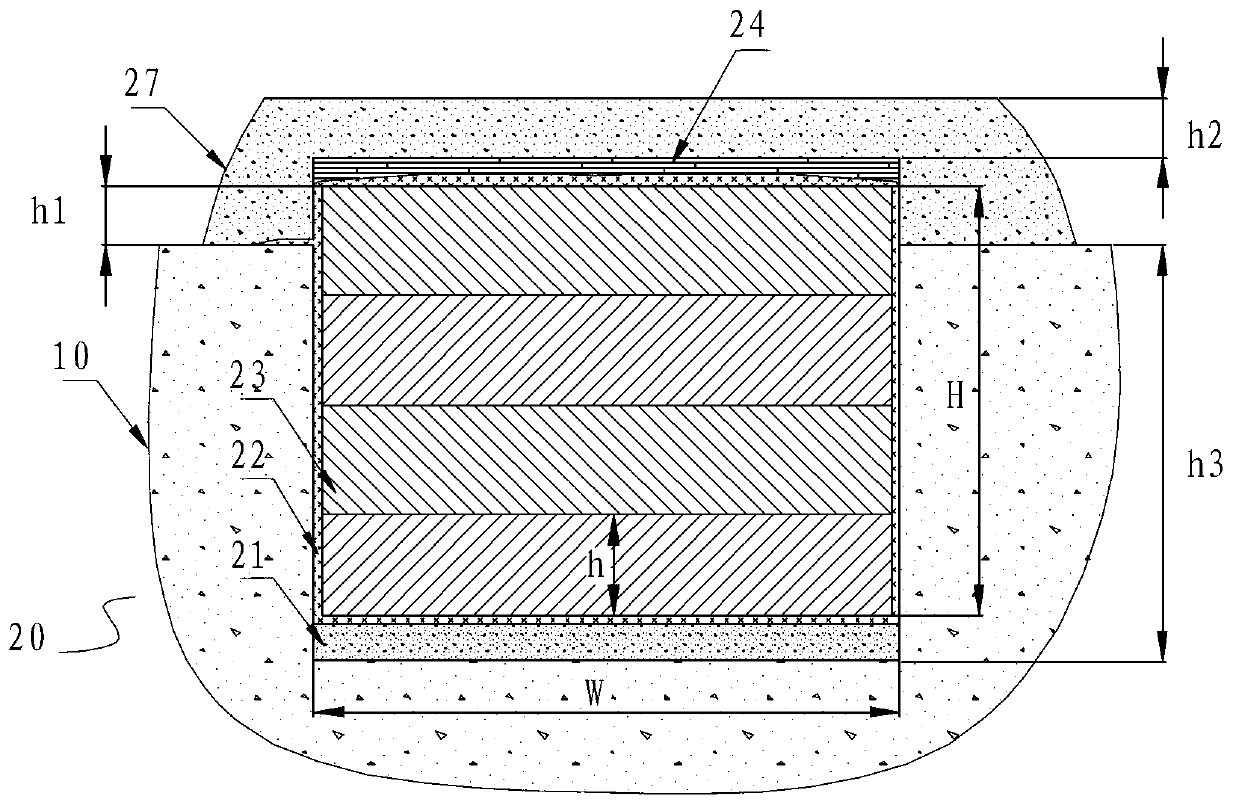

[0041] Such as image 3 Shown is a schematic diagram of the cross-sectional structure of the silage pit in Embodiment 2 of the present invention. When the amount of corn stalk silage is large, it can be compacted with heavy-duty machinery, such as a tractor, so that its exhaust effect is good and it saves time and effort. Such as image 3 Among them, only part of the silo 20 is set under the ground 10, and the height of the underground part is h3. The part of the compacted corn stalk layer 23 protrudes from the wall of the silo 20, and the protruding height is h1, and the range of h1 is 50cm-60cm. After the corn stalk layer 23 is tightly sealed by the plastic film 22, one deck of wheat straw 24 is spread on the upper end. Then the outermost layer is covered with a layer of wet soil layer 27, and the surface is patted lightly. The thickness h2 of the wet soil layer 27 is 20cm-30cm.

[0042] In the silo 20 of the present invention, the width W of the silo 20 is the same as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com