Gear of workpiece rotating stamping die

A technology for stamping dies and workpieces, applied in the field of metal processing tools, can solve problems such as low efficiency, restrict the development of enterprises, increase labor costs of enterprises, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

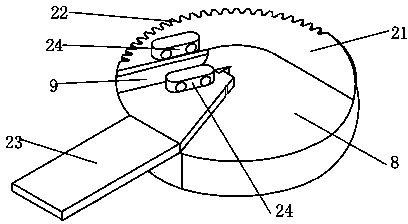

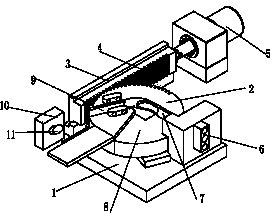

[0012] Combine below figure 1 and figure 2 Specific description embodiment:

[0013] A kind of gear of workpiece rotation punching die, comprises wheel body 21, described wheel body 21 is provided with the workpiece groove 9 that places workpiece, one end of described workpiece groove 9 extends to the edge of wheel body 21, and the workpiece groove 9 The other end extends into the wheel body 21 and is connected with a fan-shaped groove 8, and the side of the wheel body 21 away from the fan-shaped groove 8 is provided with a rack and pinion 22, and the described wheel body 21 is located between the fan-shaped groove 8 and the workpiece groove 9 One side is provided with an outwardly extending stopper 23 .

[0014] In a preferred manner, splints 24 are provided on both sides of the workpiece groove 9 .

[0015] The present invention is the core part of the workpiece rotary stamping die, and the entire workpiece rotary stamping die includes a base 1, a gear 2 is hinged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com