A rate-variable fertilizing machine used for corn and achieving self-adaptive line spacing

A fertilizer applicator and self-adaptive technology, applied in the directions of fertilizer applicator, application, planting method, etc., can solve the problems of low utilization rate of chemical fertilizer, difficulty, damage to seedlings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings.

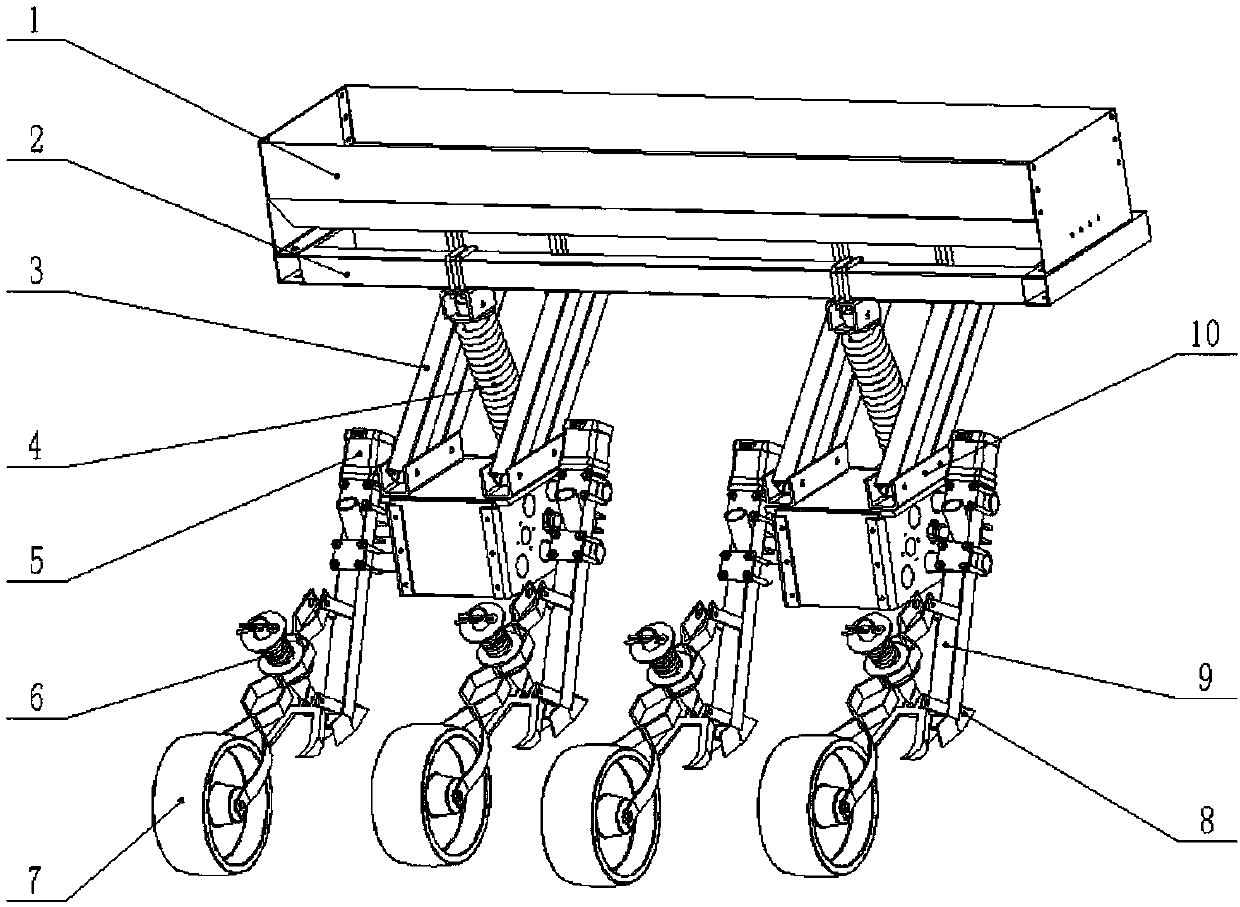

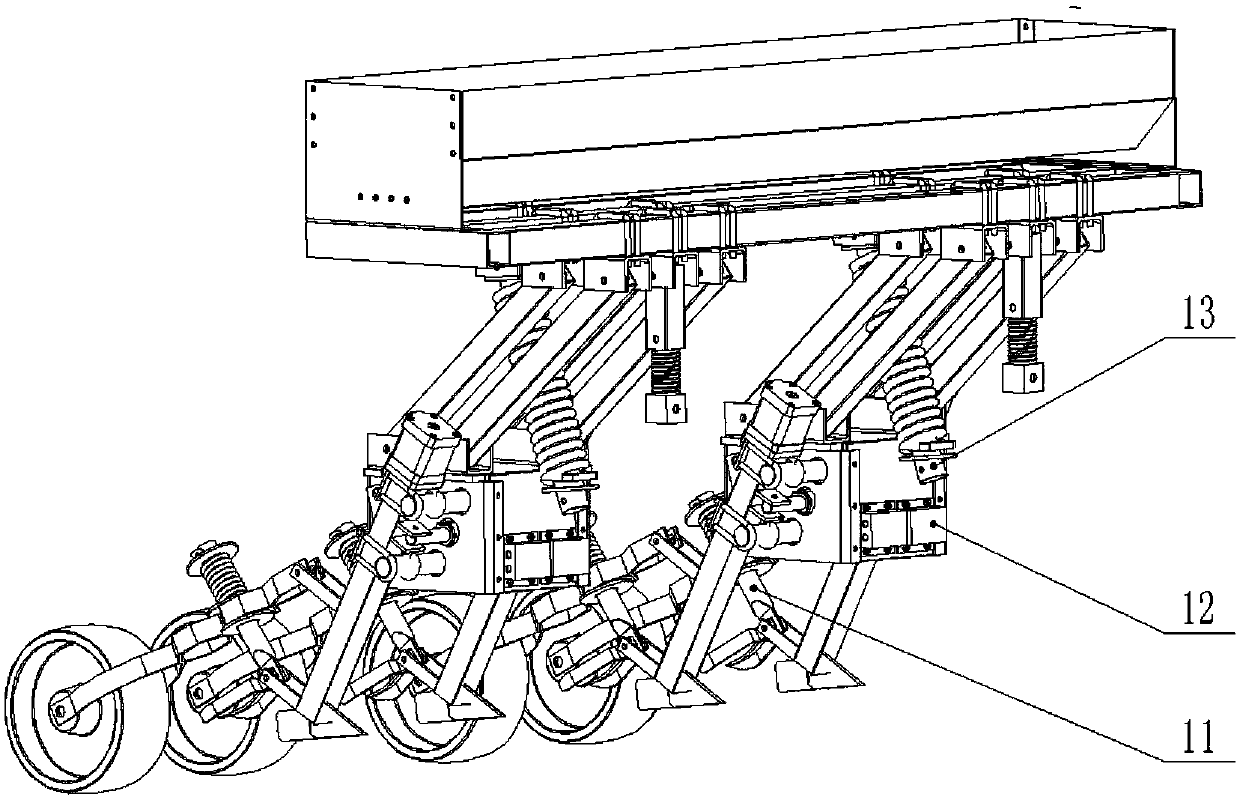

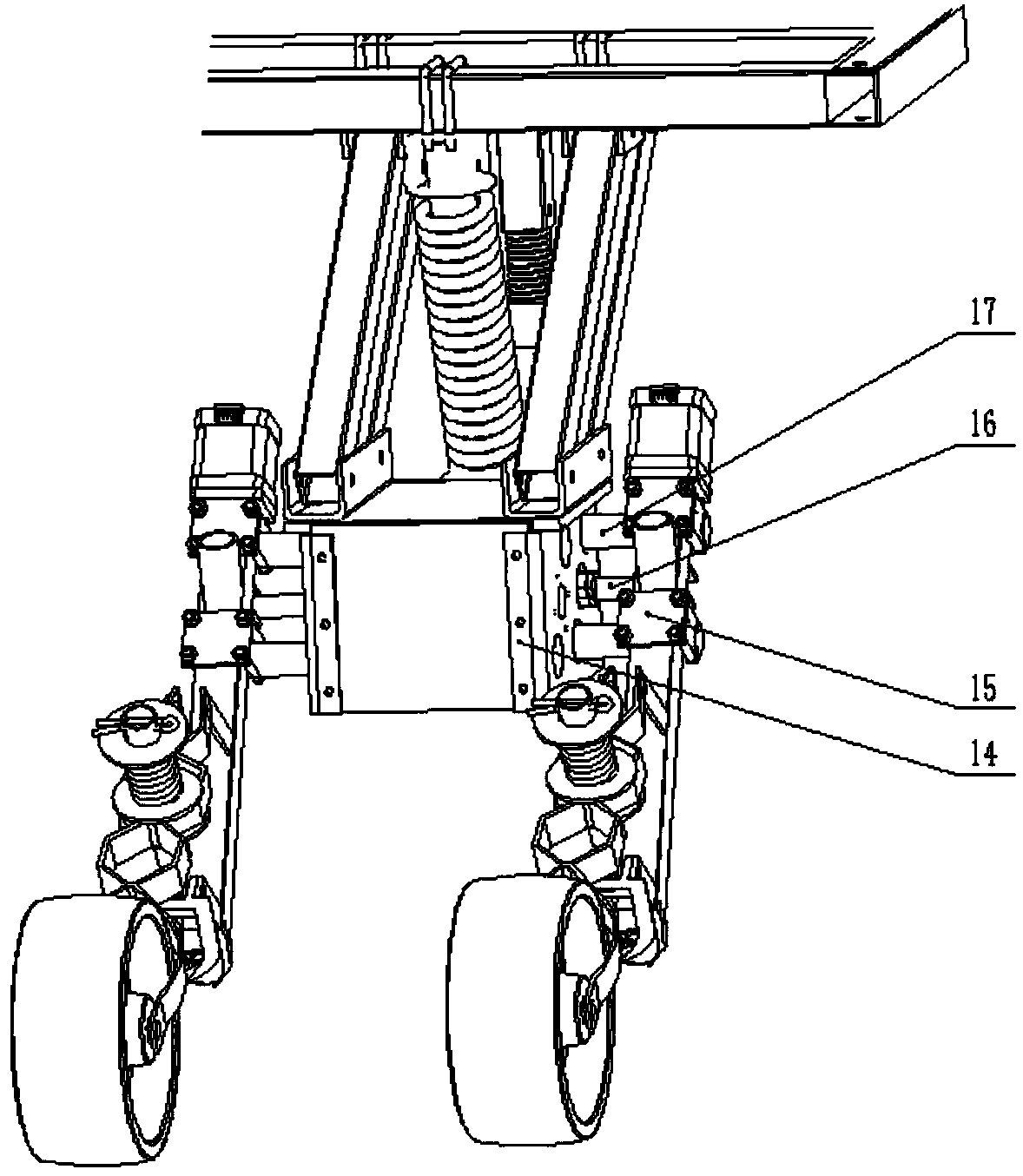

[0034] A corn variable fertilizer applicator with self-adaptive row spacing according to the present invention, the variable fertilizer applicator is mainly composed of an image pickup device, a row spacing adjustment device, an ultrasonic detection device, a variable fertilization device, a soil-covering suppression mechanism, a four-bar profiling mechanism, and a frame (2) and fertilizer box (1) form.

[0035] The image pickup device is composed of a camera (25), a damping mechanism (26) and a connecting frame (27). The shock absorbing mechanism (26) is affixed on the frame (2) through the connecting frame (27), and the camera (25) is installed on the shock absorbing mechanism (26), which can effectively alleviate the impact of the camera (25) caused by the traveling of the implement. Jitter, so as to ensure the shooting quality and improve the accuracy of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com