Seed metering apparatus applicable to precise small-quantity seeding of small-granule seeds

A seed metering device and technology for seeds, applied in the directions of planter parts, etc., can solve the problems of uniformity effect, low seeding speed, high crushing rate, and reduce shear force, extrusion force, and seed damage. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

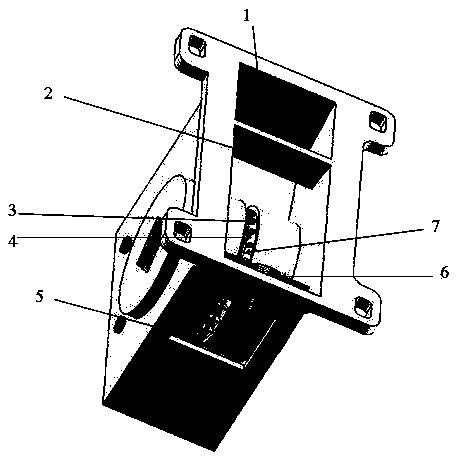

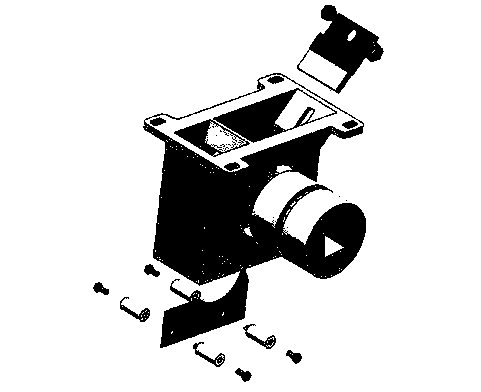

[0010] In the accompanying drawing, part of the seeds in the seed filling box (1) are filled into the seed filling tank (4) before the seeds reach the brush (6) due to the action of gravity; the seed limiting partition (2) controls the filling tank ( 4) The pressure on the inner seeds; the seeds in the seed-filling trough (4) rotate with the seed-filling trough (4) and reach the brush (6), and the seeds in the seed-filling trough (4) are on the seed block (3) Under the thrust of the seed filling slot (4), the brush (6) passes through; the seeds that do not fully enter the seed filling slot (4), due to the insufficient thrust of the seed block (3) and the resistance of the brush (6), The seeds slide into or out of the seed filling trough (4) from the gap between the seed blocking piece (3) and the bottom of the brush (6); The seeds are exported from the seed-clearing sheet (5) in the seed-clearing gap (7) to the seed-filling groove (4) for sowing, and the sowing operation is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com