Horizontal disc type weeding claw device

A disc-type, horizontal technology, applied in the field of agricultural machinery, can solve the problems of uneven growth of crops and inability to adapt to weeding between plants, and achieve the effects of reducing the rate of damage to seedlings, ingenious design and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

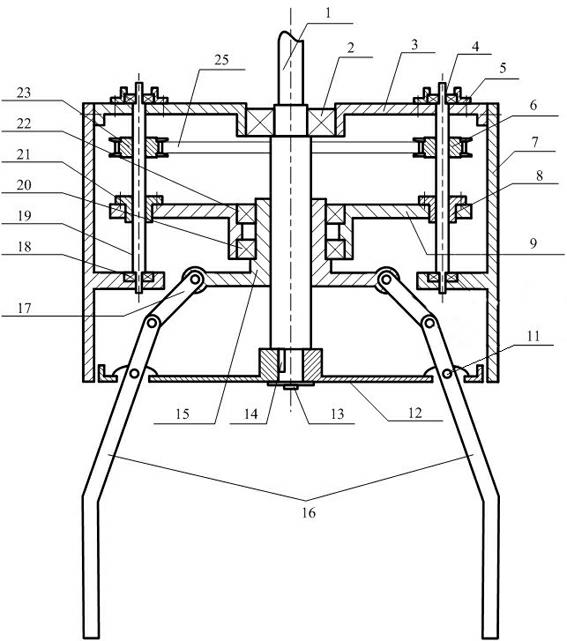

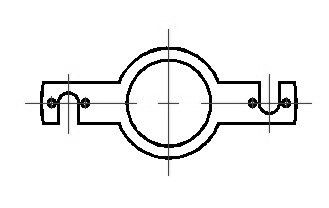

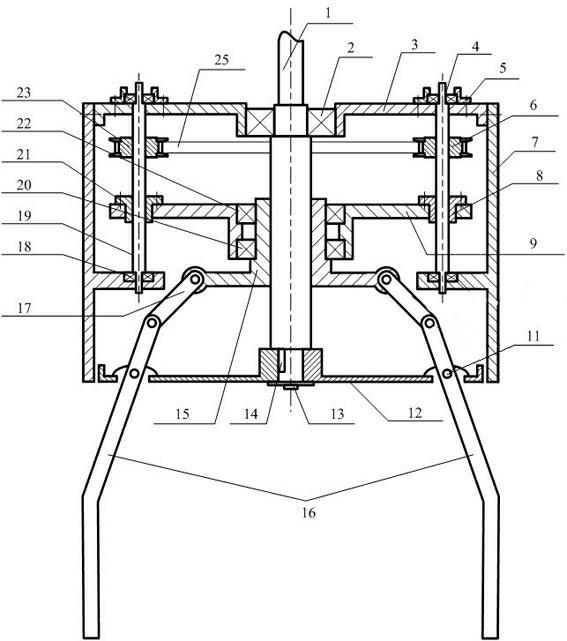

[0019] The structure diagram of the present invention is as figure 1 As shown, a horizontal disc type weeding claw device includes a main shaft 1, a housing 7, a bottom disc 12, a cover plate 3 and weeding claws 16, wherein the cover plate 3 is fixed on the shell 7, and the weeding claws 16 pass through the pin 11 is hinged with the bottom disc 12, the lower end of the main shaft 1 is connected with the bottom disc 12 through the key 14 and the fastening screw 13, the upper end is fixed on the cover plate 3 through the main shaft bearing 2, the middle part of the main shaft 1 is a spline structure, and the joint connector 15 is corresponding A spline sleeve matching the spline structure on the main shaft 1 is provided. The joint connector 15 is sleeved on the main shaft 1 through the spline sleeve. The device 15 is also provided with an adjustment plate 9, the adjustment plate 9 is connected with the joint connector 15 through the upper and lower bearings 22, 20 on the outer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com