Combined vertical comb-type weeding mechanism for crop seedling with loose soil

A technology of comb teeth and seedling strips, which is applied in the field of seedling strip loosening and weeding operation mechanisms, can solve the problems of poor stability and adaptability of weeding parts, unreasonable movement track of entry into the soil, poor ability of weeding teeth to enter the soil, etc., to achieve uniform force, The effect of small vibration and low seedling injury rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

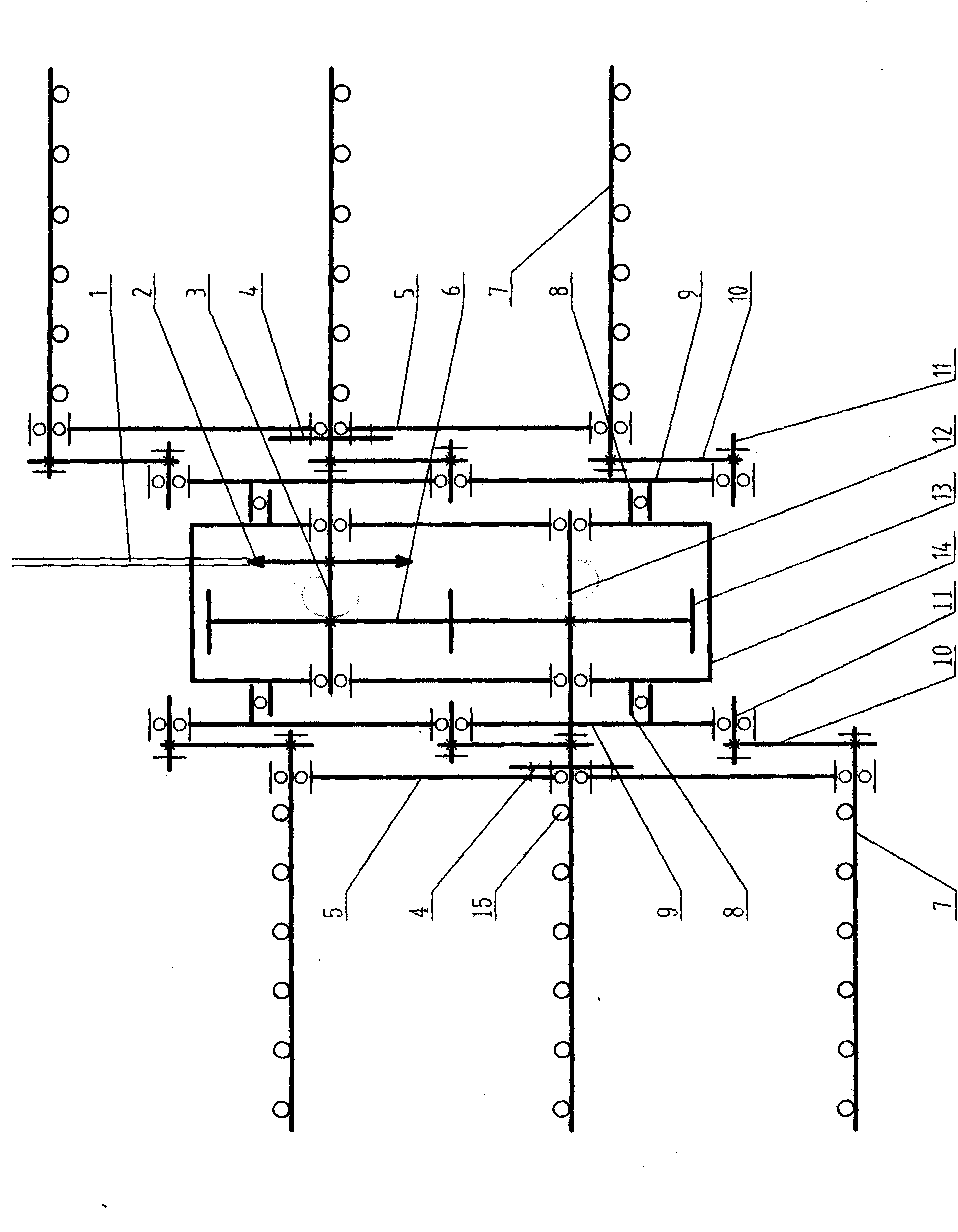

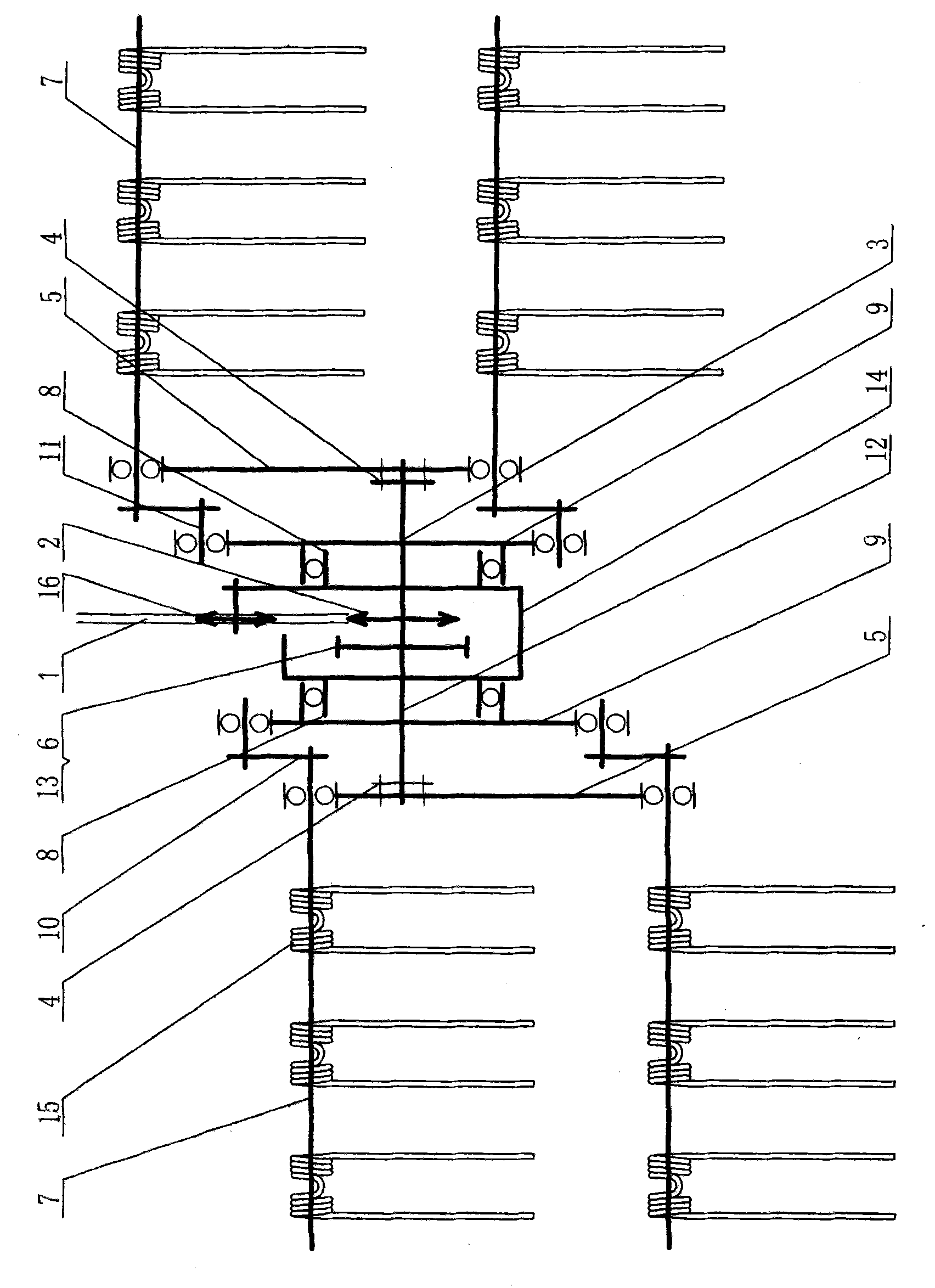

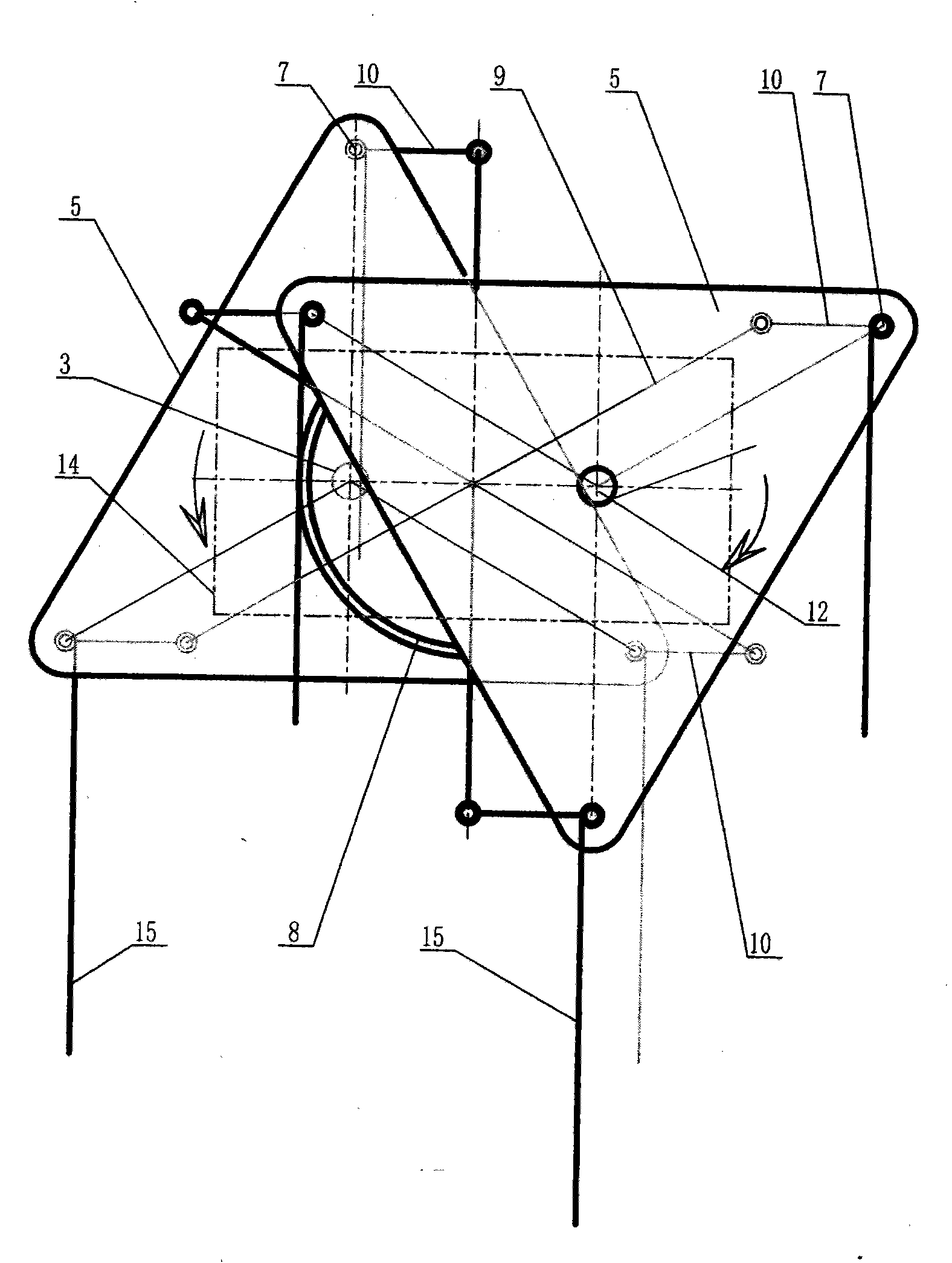

[0011] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. Combine upright comb-tooth type crop seedling belt loosening and weeding mechanism, on the transmission box body 14, equip the power rear output shaft 3 and the power front output shaft 12 parallel to each other, and output the power after being positioned at the power of the transmission box body 14 boxes The driving sprocket 2 and the driving cylindrical gear 6 are fixedly installed on the shaft 3, and the driven cylindrical gear 13 is fixedly mounted on the power front output shaft 12 at the position inside the transmission box 14, and the driven cylindrical gear 13 meshes with the driving cylindrical gear 6; The power output shaft 3 is positioned at the rear end of the transmission case 14 outside and the front end of the power front output shaft 12 is positioned at the transmission case 14 outside. The driving disc 5 is dislocated by 180° in the cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com