Lateral retractable intertillage weeding unit

A telescopic, single-body technology, applied in the field of agricultural machinery, can solve the problems of damaged seedlings and seedling damage rate, and achieve the effects of low seedling damage rate, novel structure and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

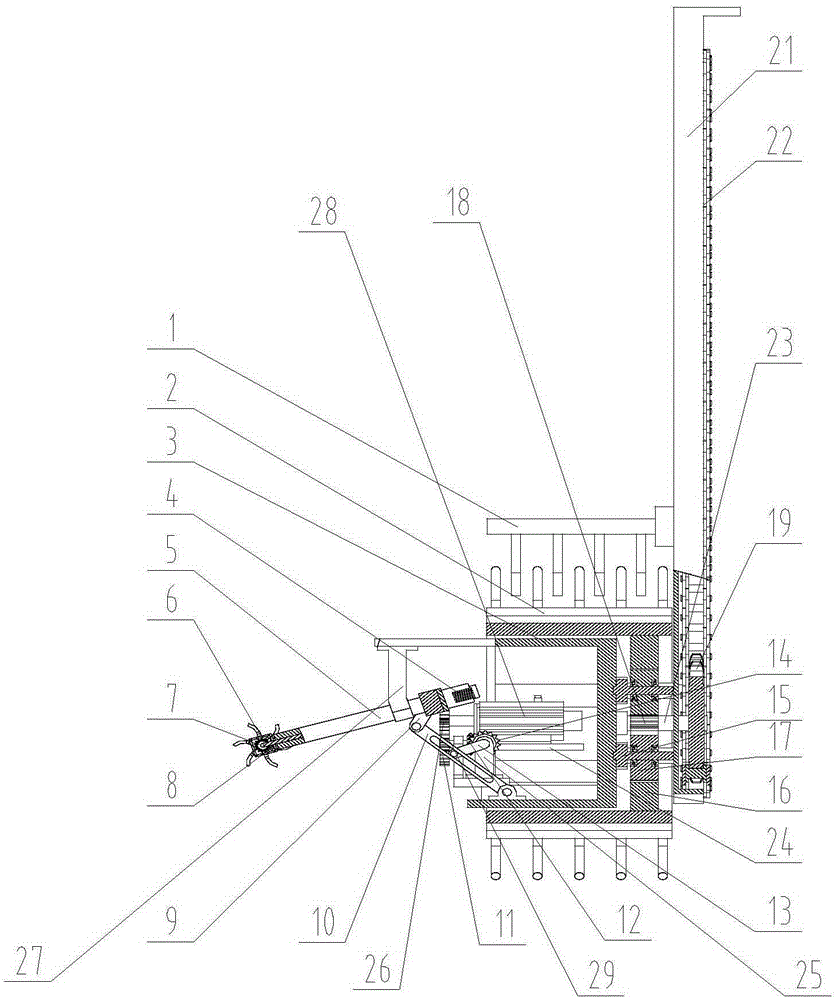

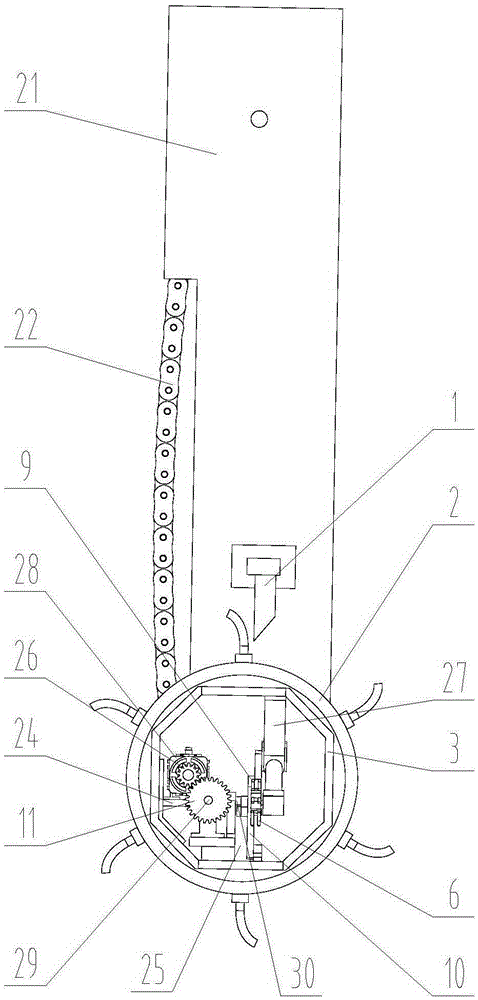

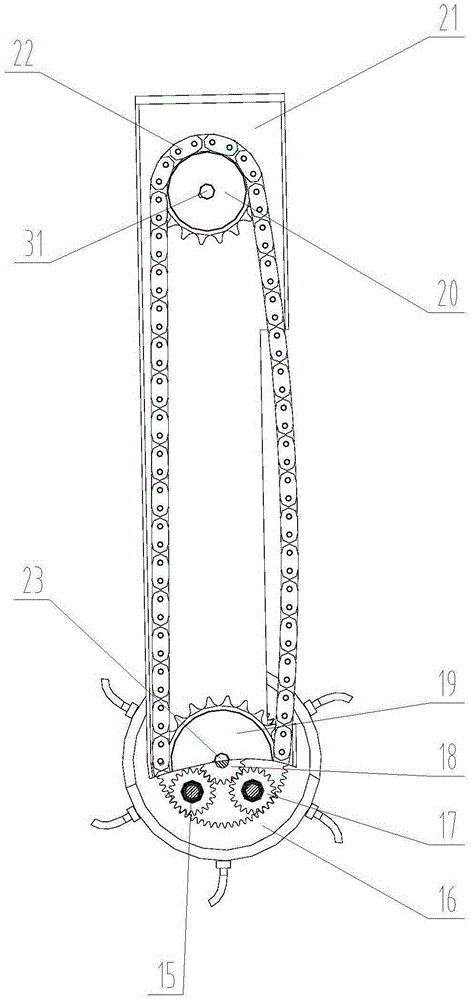

[0010] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A laterally telescopic cultivating and weeding unit, on the upper and lower sides of the unit plate 21, the power input shaft 31 and the main drive shaft 23, the driving sprocket 20 and the driven sprocket are respectively installed parallel and rotatable. 19 are respectively fixed on the power input shaft 31 and the main drive shaft 23, and the chain 22 is sleeved on the main and driven sprockets 20, 19; the sun gear 18 is fixed on the main drive shaft 23, and on the single plate 21 on the lower side, located on the sun gear 18 outside the rotatable inter-row weeding tooth roller assembly 2, the inner ring gear 16 is fixed on the inner side wall surface of the inter-row weeding tooth roller assembly 2, on the said monomer The lower side of the plate 21 is installed with a fixed inner casing 3 through the planetary gear shaft 15. The fixed inner casing 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com