Offset double-disc clamping air suction type seed sowing device

A double-disc, air-suction technology, applied in the direction of seeder parts, etc., can solve the problems of poor size adaptability, low operating speed, and low seeding accuracy, and achieve the goal of reducing seed damage rate, increasing operating speed, and uniform sowing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

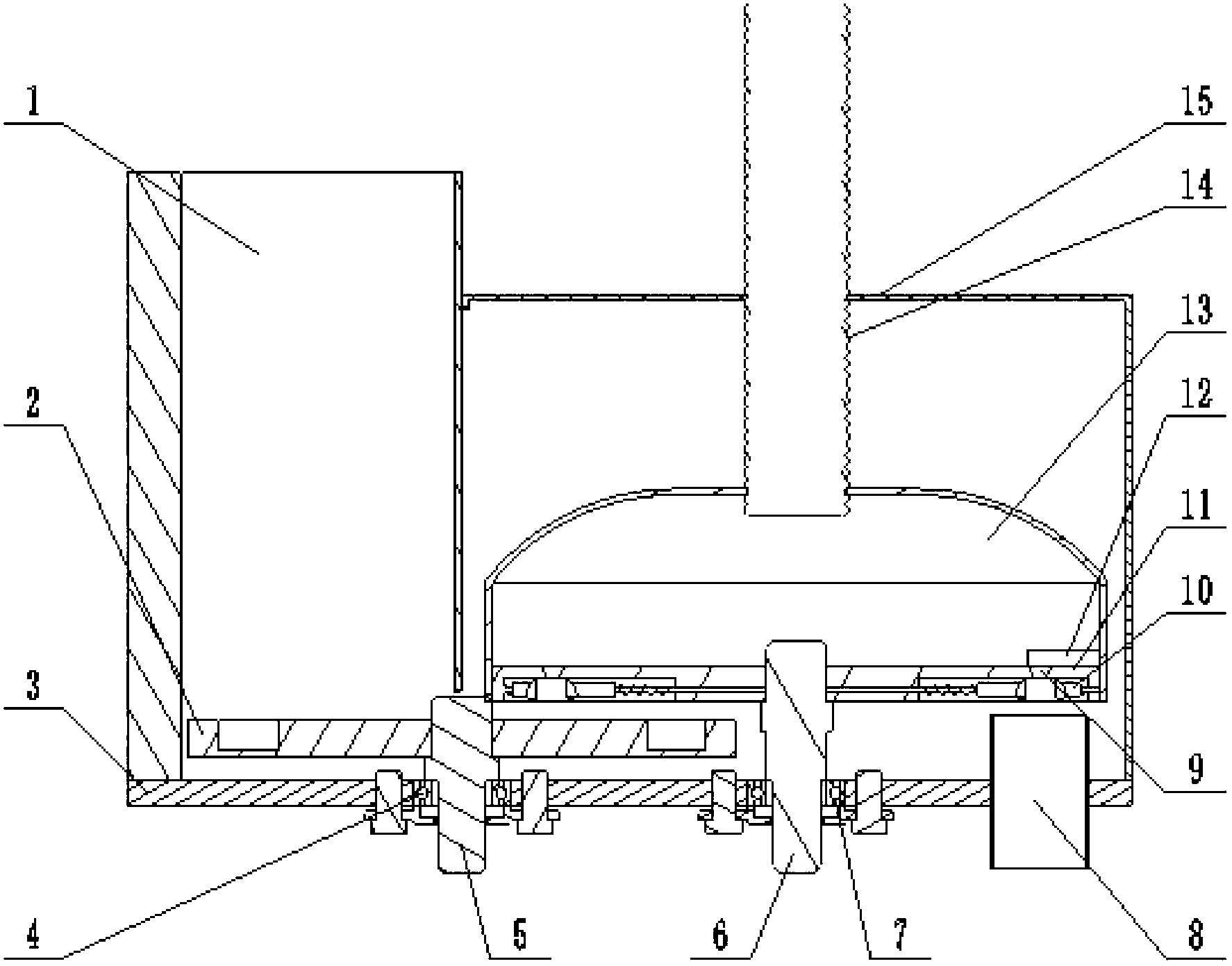

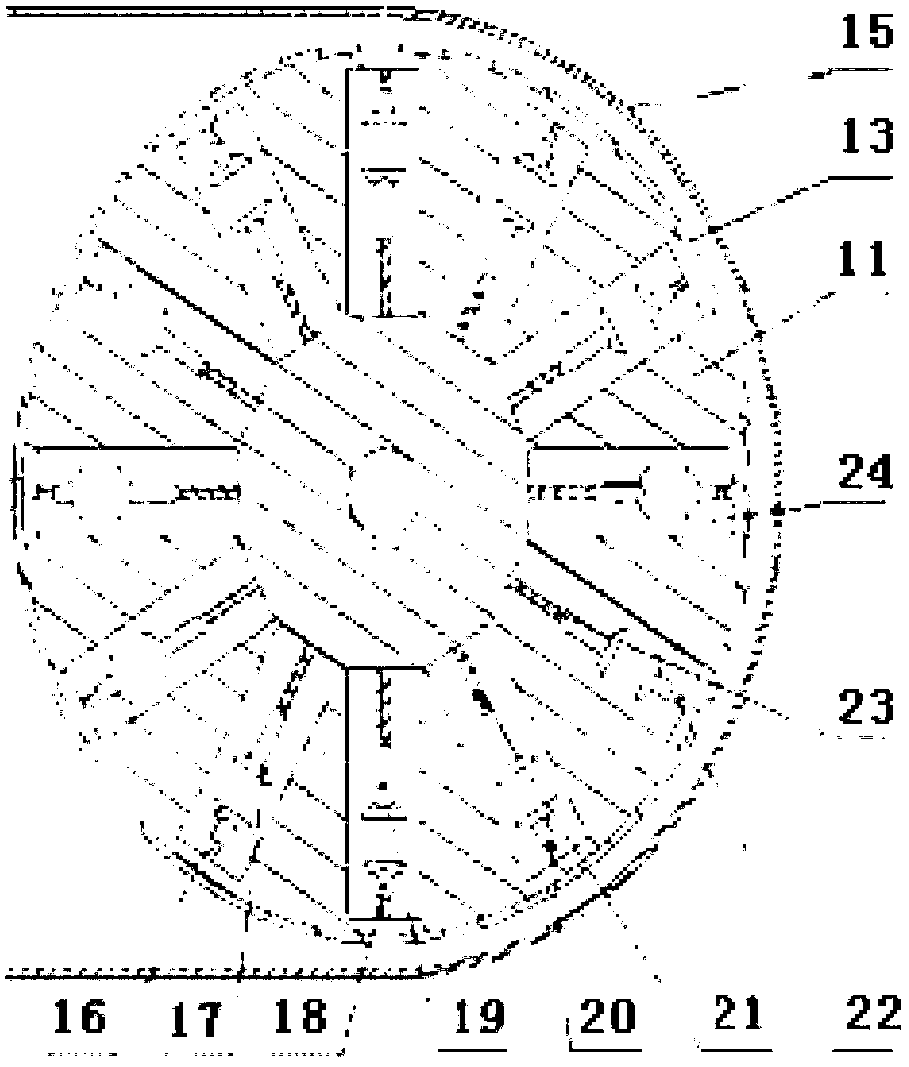

[0019] The specific content of the present invention is further described below in conjunction with the embodiment shown in the accompanying drawings:

[0020] When filling seeds, the seeds in the seed box 1 fall into the groove of the seed disc 2, and rotate to the sowing sucker 11 below with the seed disc 2. The blower fan makes the upper and lower sides of the sowing suction cup 11 produce negative pressure, and the airflow generates movement. The seeds in the groove are subjected to the suction effect produced by the airflow movement and begin to displace, and move toward the seed suction hole 9 directions. Because the lowermost end face of the seed suction hole 9 is a circle with a radius of 3mm, and the spherical rate of soybean seeds is greater than 90% and the radius is greater than 3mm, so the seeds that first contact the seed suction hole 9 will block the lower end of the seed suction hole 9, so that The gas at the lower end of the seed suction hole 9 stops flowing, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com