Side-filling front-throwing precise seeding device and seeding method thereof

A kind of seed metering and precision technology, which is applied in the direction of sowing, planter parts, hole sowing seeders, etc., can solve the problems of poor population mobility, holes, missed sowing, clearing range and non-adjustable seeding height, etc., to achieve Good cavitation, reduced seeding rate, and good seeding consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

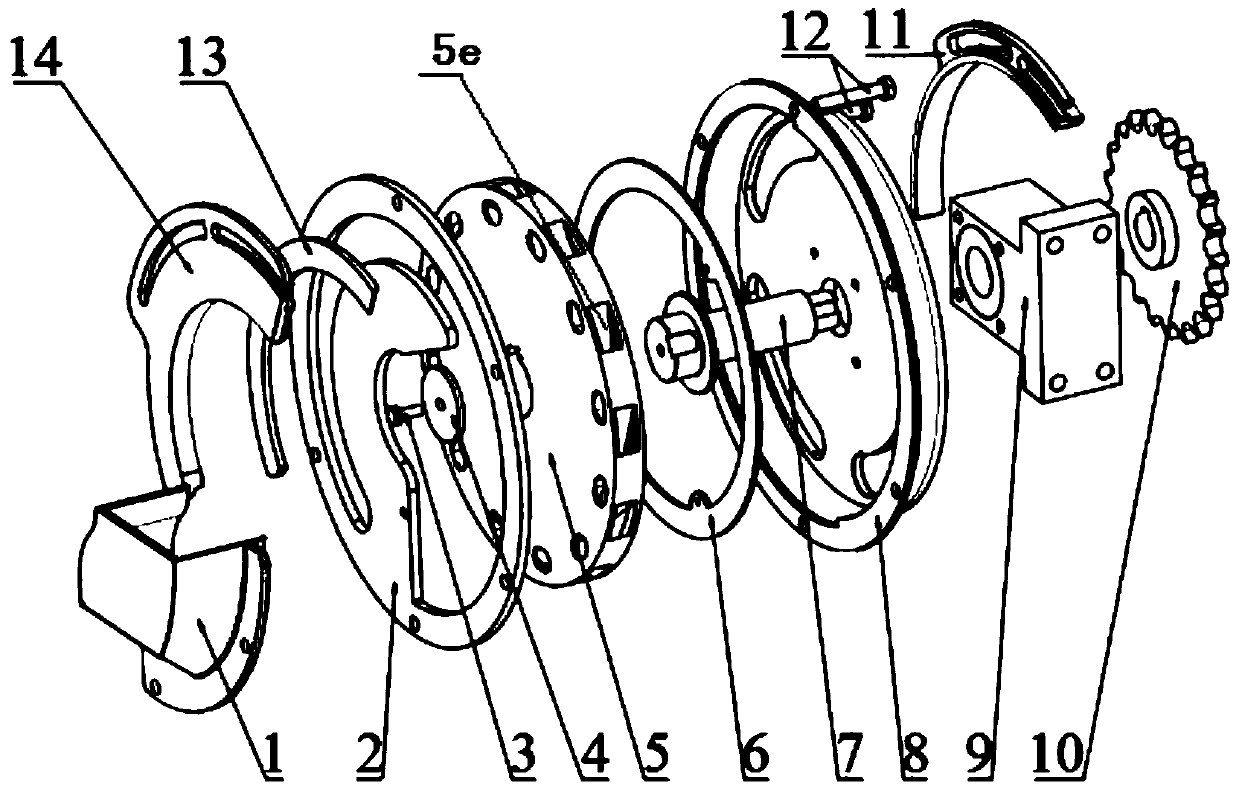

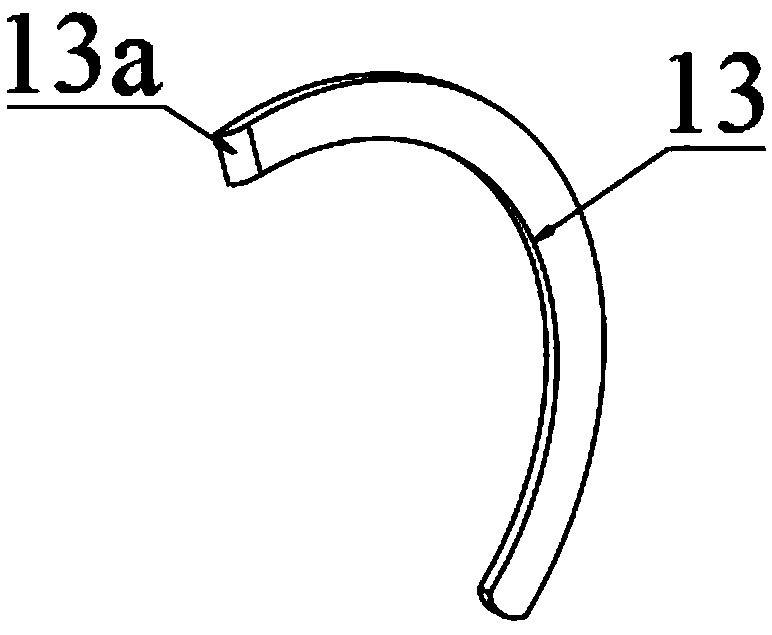

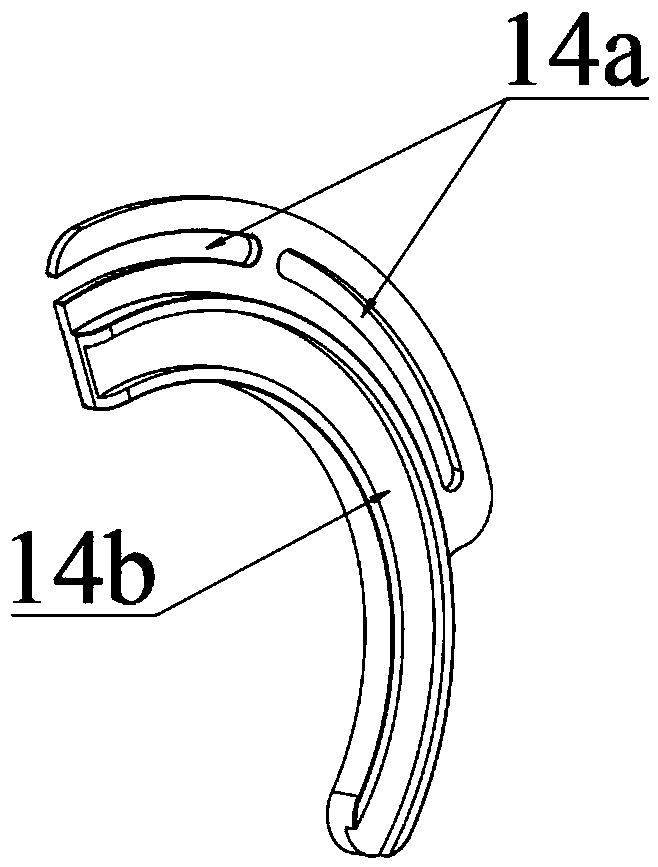

[0036] refer to Figure 1 to Figure 8 The side-filling and positive-throwing precision metering device shown includes a housing 8, a seeding wheel 5 arranged in the housing 8, and a rotating assembly for driving the seeding wheel 5 to rotate. The rotating assembly includes a rotating Shaft 7 and bearing seat 9, described housing 8 is fixedly installed on bearing seat 9, and one end of rotating shaft 7 passes bearing seat 9 and housing 8 and is fixedly connected with the center of seeding wheel 5, and housing 8 is installed with The cover plate 2 that closes itself, the side of the cover plate 2 away from the seed wheel 5 is equipped with a sealing plate 14 and a seed box 1, and the side of the seed wheel 5 near the seed box 1 is provided with several holes that can be connected with the seed box 1 The connected seed inlet 5a, the seed wheel 5 is provided with an annular groove 5d and several bag seed pockets 5b arranged in the annular groove 5d, the housing 8 is equipped with ...

Embodiment 2

[0044] refer to Figure 1 to Figure 8 The side-filling and positive-throwing precision metering device shown includes a housing 8, a seeding wheel 5 arranged in the housing 8, and a rotating assembly for driving the seeding wheel 5 to rotate. The rotating assembly includes a rotating The shaft 7 and the bearing seat 9, the housing 8 are fixedly installed on the bearing seat 9, one end of the rotating shaft 7 passes through the bearing seat 9 and the housing 8 and is fixedly connected with the center of the seed wheel 5, and the housing 8 is equipped with a self-closing The cover plate 2, the side of the cover plate 2 away from the seed wheel 5 is equipped with a sealing plate 14 and the seed box 1, and the side of the seed wheel 5 close to the seed box 1 is provided with several seed inlets that can communicate with the seed box 1 mouth 5a, the seed wheel 5 is provided with an annular groove 5d and several pockets 5b arranged in the annular groove 5d, the housing 8 is equipped...

Embodiment 3

[0053] A seed metering method of a side-filling positive-throwing precision seed metering device, comprising the following steps:

[0054] S1: When it is necessary to adjust the self-weight cleaning range of seeds, unscrew the locking bolt 12 connecting the cover plate 2 and the sealing plate 14, rotate the sealing plate 14 to the predetermined position along the arc direction of the guide groove 2a of the cover plate 2, and tighten the lock Tighten the bolt 12 to complete the adjustment of the seed self-weight cleaning range;

[0055] S2: When it is necessary to adjust the seeding height, unscrew the locking bolt 12 connecting the shell and the seeding positioning plate 11, rotate the seeding positioning plate 11 to the predetermined position along the arc direction of the side surface of the seeding wheel 5, and tighten it Tighten the bolt 12 to complete the adjustment of the seeding height;

[0056] S3: When working, the sprocket 10 drives the seed wheel 5 to rotate counte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com