Paddy-bud seeder

A seeding machine and seedling technology, which is applied in the field of agricultural machinery, can solve the problems of high price, low seedling quality, and low seeding quality, and achieve the effects of increasing production efficiency, improving seedling quality, and promoting machine-transplanting technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

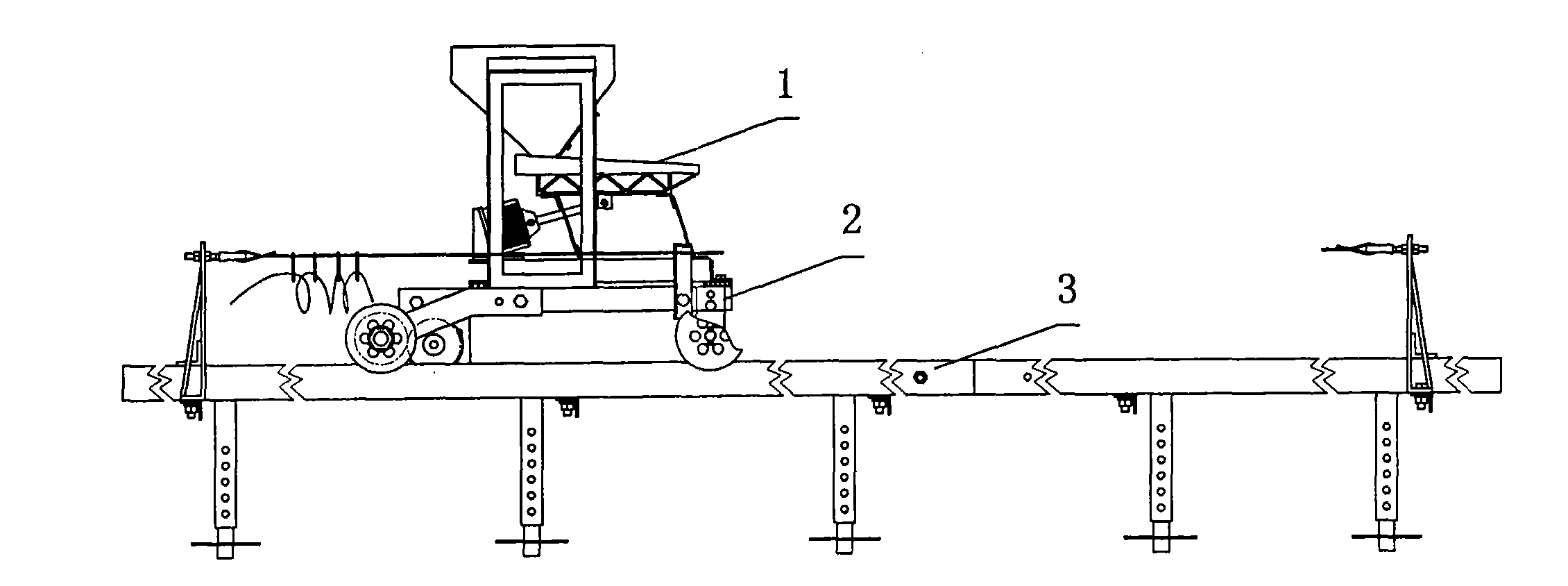

[0030] Such as figure 1 As shown, the rice bud seed planter of the present invention is composed of a dense groove type electromagnetic vibrating seed metering device 1, an electronically controlled sowing mobile platform 2, a track frame 3 and a DC power supply. The dense-groove electromagnetic vibrating seed metering device 1 is installed on the electronically controlled sowing mobile platform 2, and then placed on the track frame 3 as a whole, connected to a DC power supply, and moves back and forth on the track frame 3 for seeding as a whole.

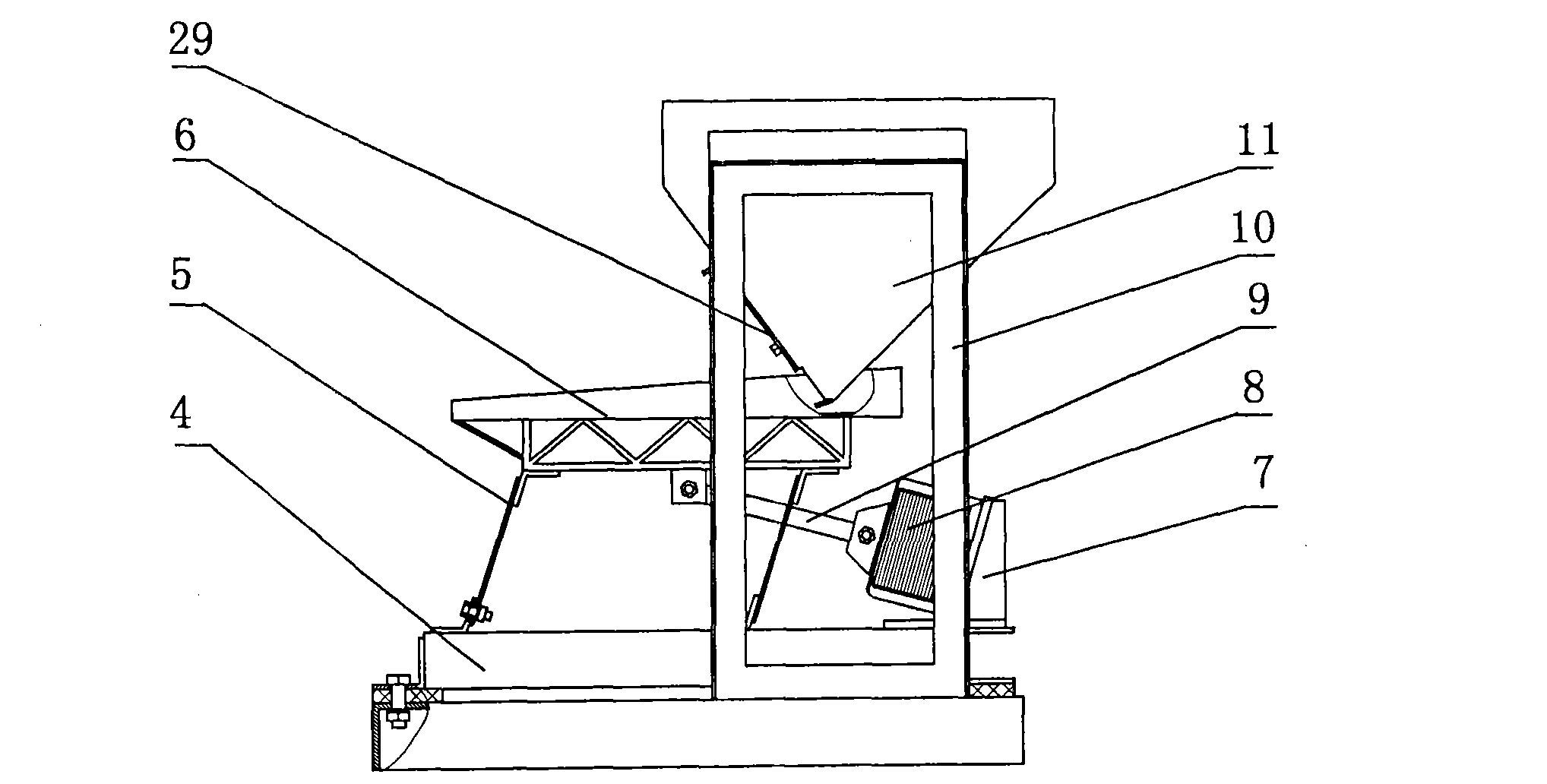

[0031] Such as figure 2 As shown, the dense groove type electromagnetic vibration seed metering device 1 is composed of a seed metering device base 4, a leaf spring 5, a seeding disc 6, an electromagnet support 7, an electromagnet 8, a vibration connecting rod 9, and a seed box support 10 And the seed box 11 is assembled, wherein, the seed box 11 is fixed on the electric control type sowing mobile platform 2 through the seed box b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com