Seeding device for saline-alkali soil

A seeding device and saline-alkali land technology, applied to shovels, plows, agricultural machinery and implements, etc., can solve the problems of poor seedling growth quality, poor ridging effect, and inability to complete multiple processes at one time, so as to achieve uniform sowing and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

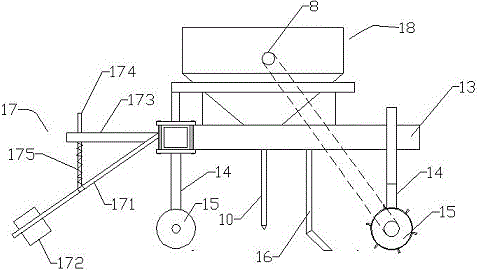

[0030] Examples such as figure 1 , figure 2 , image 3 Shown, a kind of sowing device for saline-alkali land comprises frame 13, and the lower part of frame 13 is fixedly connected with liftable support leg 14, and is rotatably connected with traveling wheel 15 on the support leg 14, and the top of frame 13 is fixedly connected with The planting mechanism 18, the bottom of the frame 13 is also fixedly connected with a ridging shovel 16 for ridging, and the afterbody of the frame 13 is provided with a leveling mechanism 17 for leveling the top of the ridge.

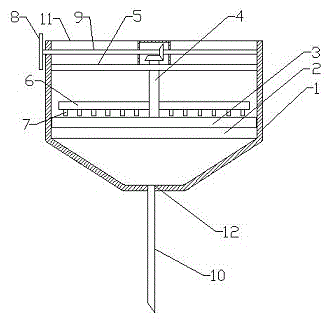

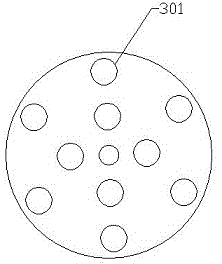

[0031] The planting mechanism 18 includes a hopper 1, the hopper 1 has a feed port 11 and a discharge port 12, a fixed disk 2 is fixedly connected to a position close to the discharge port 12 in the hopper 1, and a turntable 3 is connected to the fixed disk 2 for rotation. The center position of the turntable 3 is fixedly connected with the rotating shaft 4, and the drive shaft 9 is connected to the rotating shaft 4. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com