Inter-plant electrically driven hoeing control system

A control system and inter-plant technology, applied in the field of control systems, can solve the problems affecting the sustainable development of agricultural production, dietary health, agricultural product drug residues, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

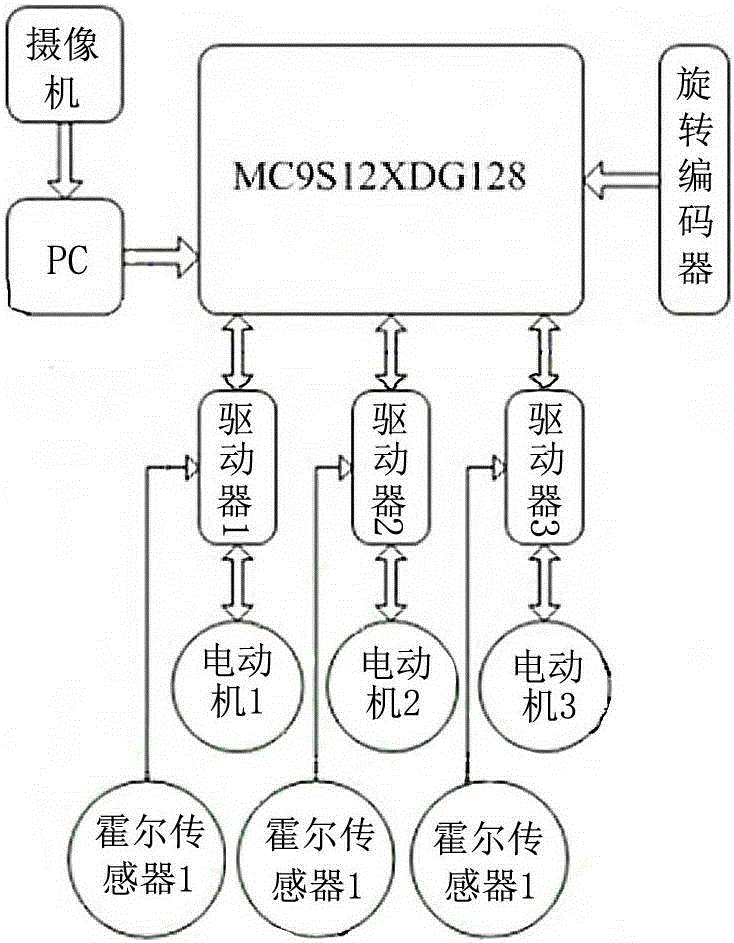

[0016] As shown in Fig. 1, the inter-plant electric drive weeding control system is composed of the knife and seedling distance information acquisition module, the speed information acquisition module, the motion execution unit and the motor angle return module. The knife-seedling distance information acquisition module uses the camera to dynamically obtain the field seedling grass image in real time and input it to the PC for image processing to obtain the knife-seedling distance information. The speed information acquisition module measures the forward speed in real time through the rotary encoder installed on the speed measuring ground wheel shaft. The operation execution unit is composed of a driver and a motor, and the motor drives the disc hoe to move. This design involves the control of three mutually independent operation execution units. The motor angle return module adopts Hall sensor signal to input corresponding driver and makes the motor angle return to zero. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com