Negative pressure seed sucking and positive pressure seed cleaning type precise seed-metering device and seed-metering method thereof

A seed metering and negative pressure technology, which is applied to the parts of the planter, can solve the problems of coordinating the seeding speed and the quality of seeding, the wear of the seeding device, and the overall work effect of the air chamber, so as to improve the seeding effect and reduce the damage. seed rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further explained below with reference to the drawings and examples.

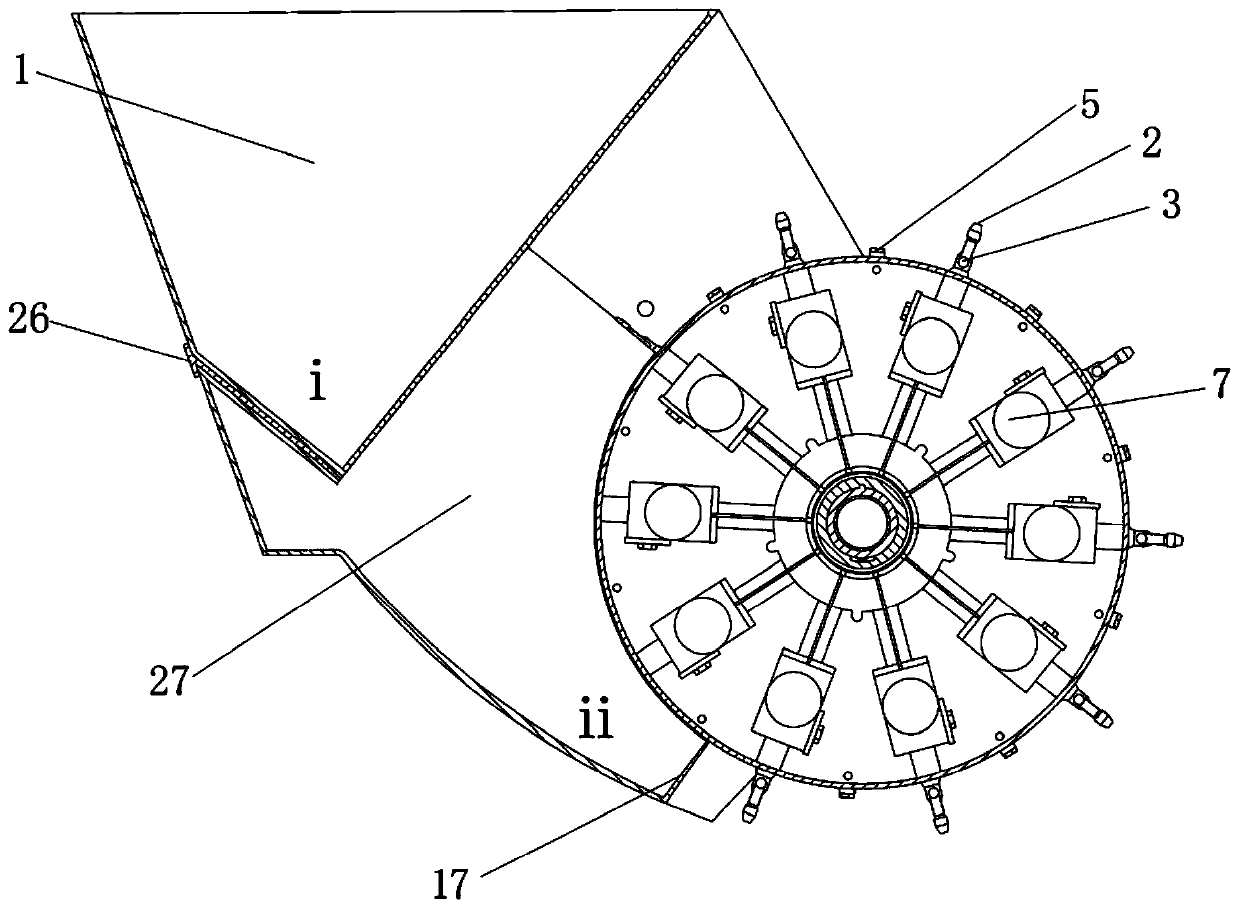

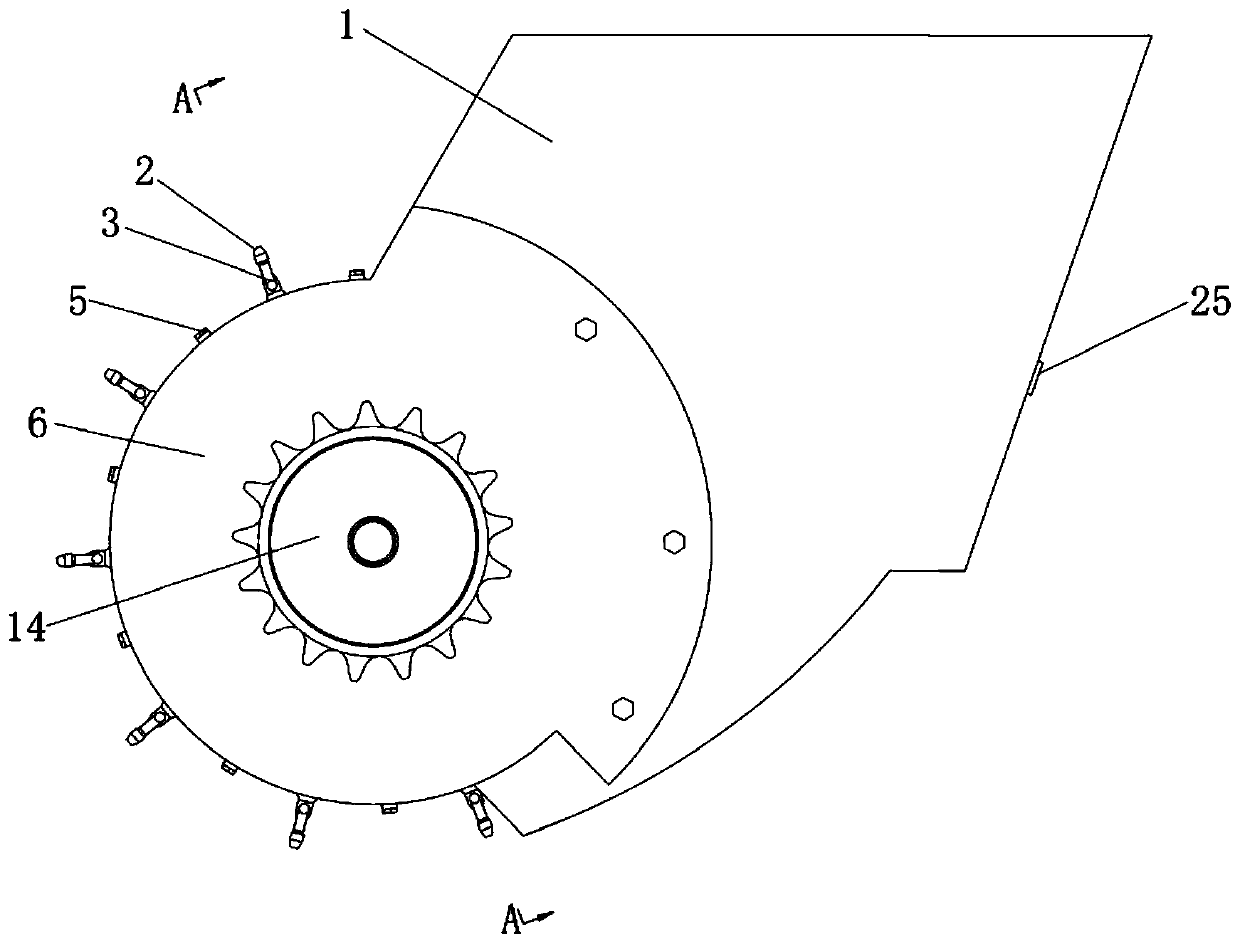

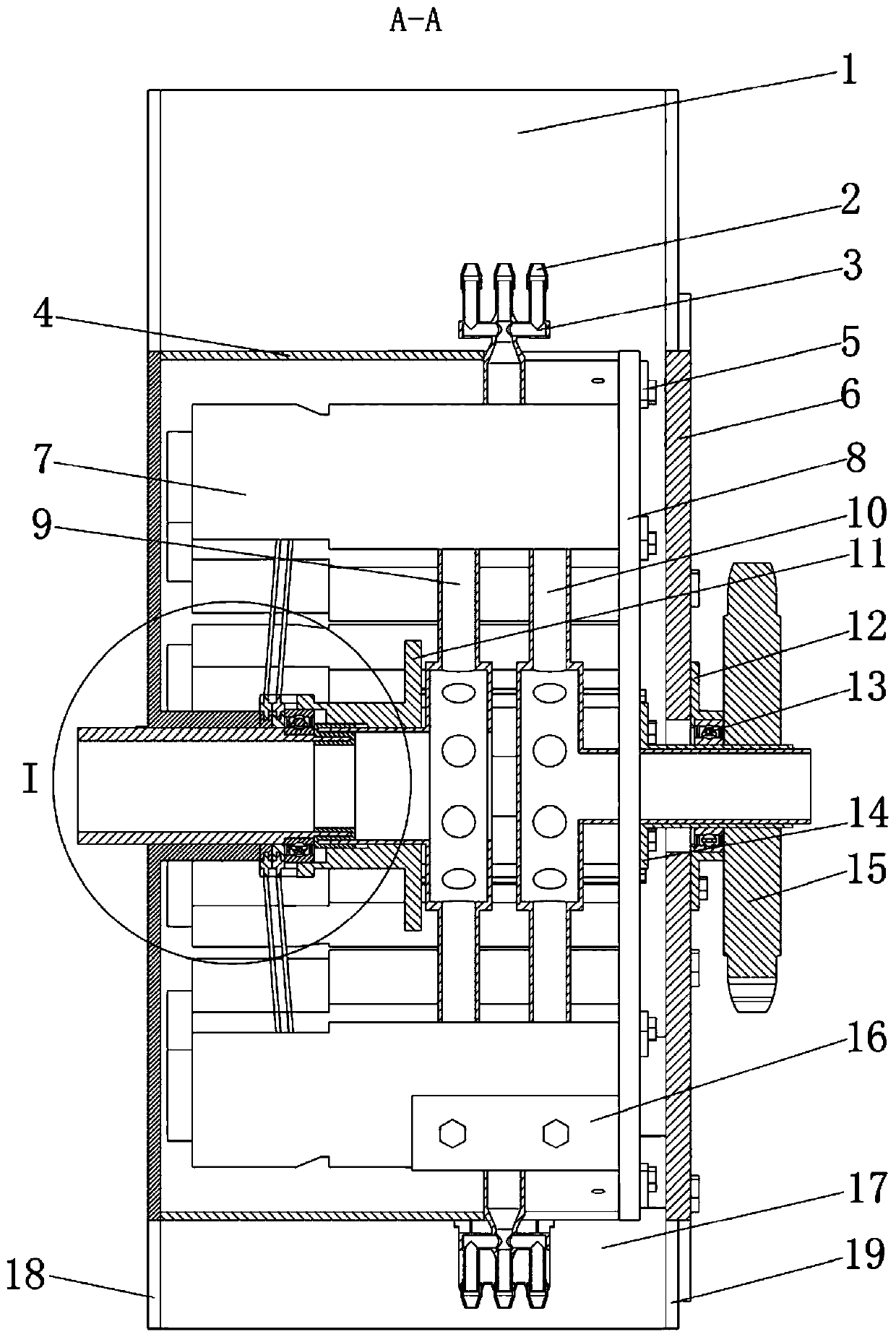

[0036] Such as Figure 1~7 As shown, a negative pressure suction seed positive pressure clear type precision seed metering device includes a seed chamber 1, a seed suction nozzle 2, a seed suction branch 3, a side panel 4, a side panel fixing piece 5, and a right cover plate 6, Two-position three-way solenoid valve 7, support plate 8, negative pressure tube 9, positive pressure tube 10, support frame 11, bearing seat 12, bearing 13, hollow shaft 14, power wheel 15, solenoid valve fixing plate 16, flexible gear Plate 17, left panel 18, right panel 19, combined brush ring 20, main control slip ring guide 21, air suction duct 22, support frame bearing 23, sealing ring 24, negative slip ring guide 25, current limiting plate 26, The middle partition 27, the rear arc plate 28, the front panel 29, the wire 30, the non-conductive track 31, the conductive track 32, the brush fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com