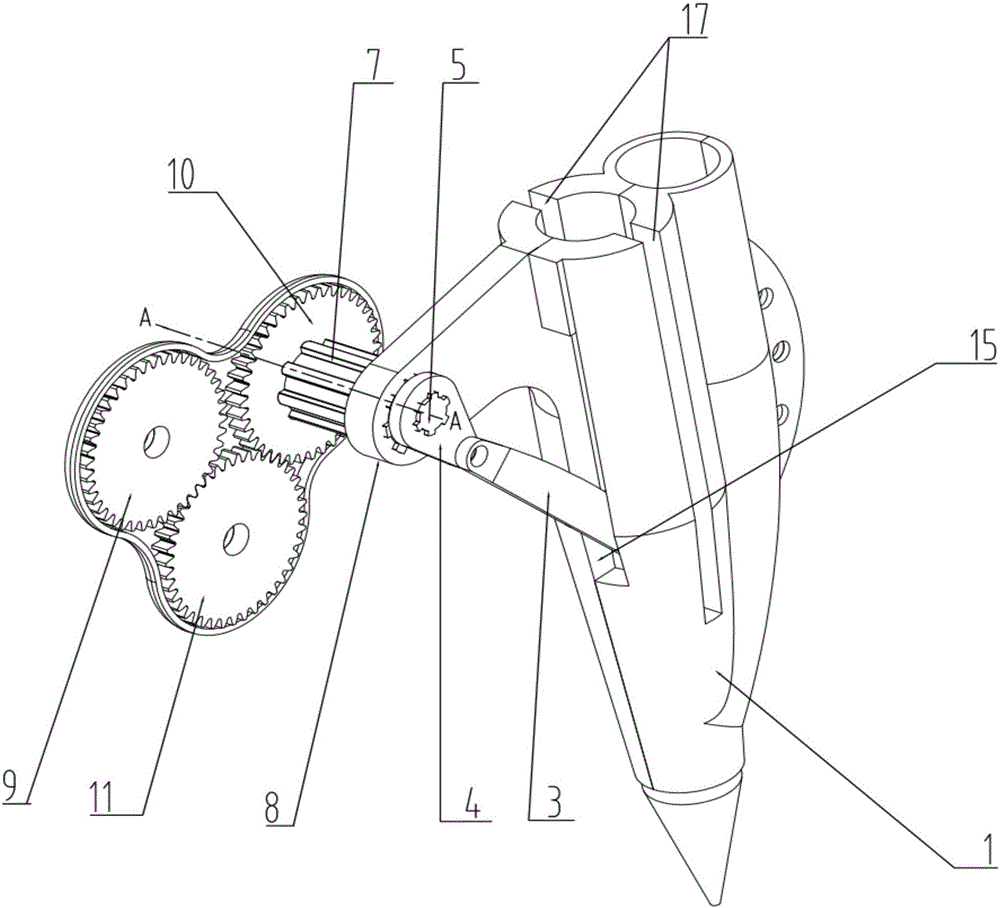

Mechanism for combining hole pricking work as well as ejecting and applying work of solid fertilizers

A combined mechanism and fertilizer technology, applied in agriculture, fertilization devices, fertilizer distributors, etc., can solve the problems of large overall size, poor fertilization accuracy, complex structure, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

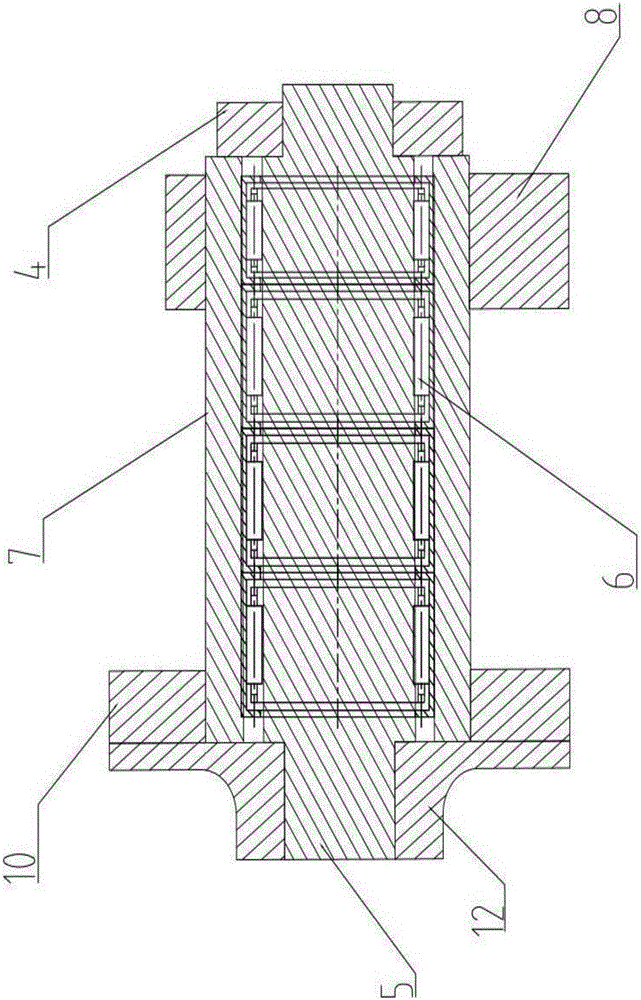

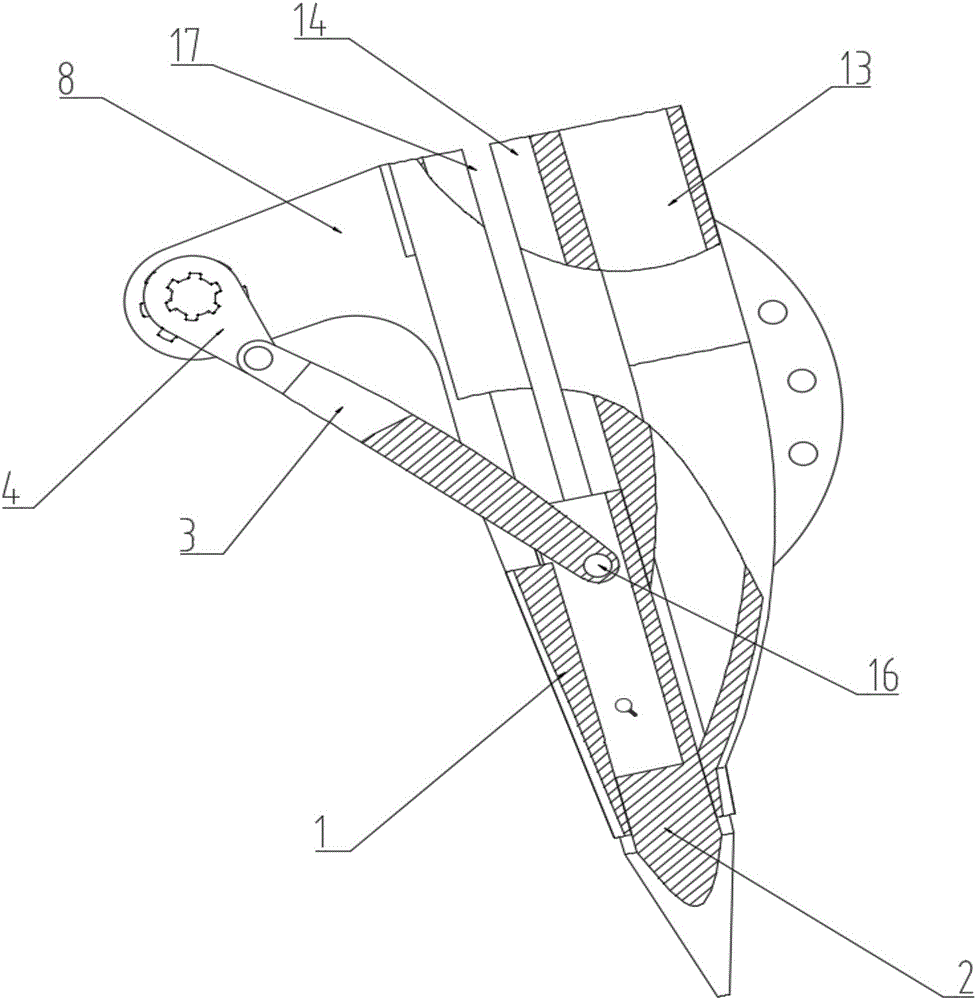

[0013] The following describes in detail the creative implementation of the present invention with reference to the drawings. A combined mechanism for piercing and injecting solid chemical fertilizers. The left half shell 8 is fastened and fixed to the right half shell 1, and the hole piercing piston cavity is formed in the left half shell 8 and the right half shell 1 14 and the fertilizer delivery cavity 13, the lower part of the fertilizer delivery cavity 13 is in communication with the lower side of the hole pricking piston cavity 14, and the hole puckering piston 2 is mounted in the hole pricking piston cavity 14 so as to move up and down and axially. The opposite side walls of the half-shell 8 and the right half-shell 1 are respectively provided with up and down piston anti-rotation chute gaps 17; the left half-shell 8 is fixedly mounted with an external spline sleeve 7, and the needle bearing 6 The spline mandrel 5 is rotatably installed in the sleeve hole of the outer sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com