Automatic adhesive tearing-off equipment and method

An automatic and equipment technology, applied in chemical instruments and methods, lamination auxiliary operations, sending objects, etc., can solve the problems of increasing enterprise management and labor costs, low work efficiency, workpiece pollution and oxidation, etc., to reduce pollution and oxidation, The effect of low labor intensity and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

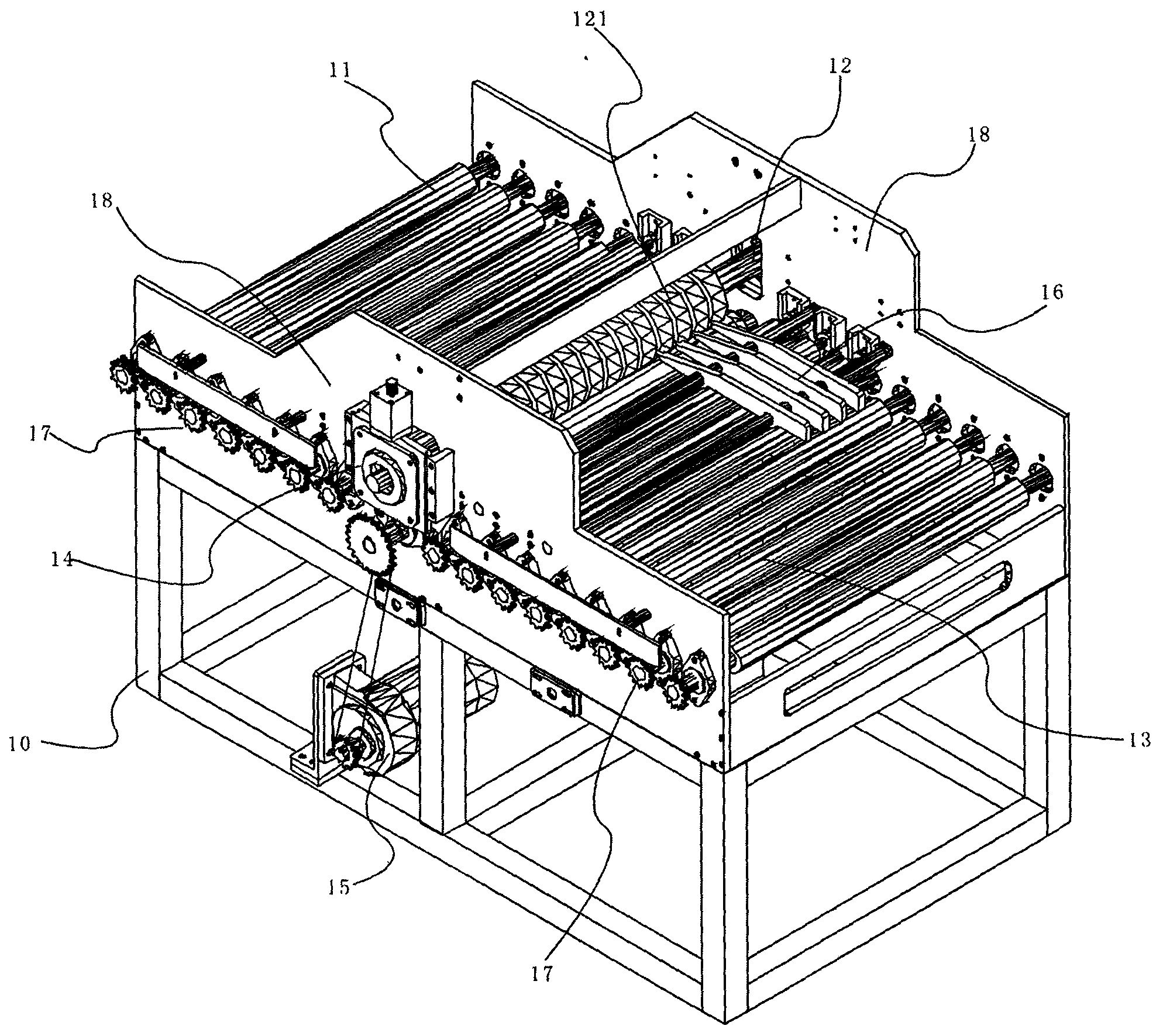

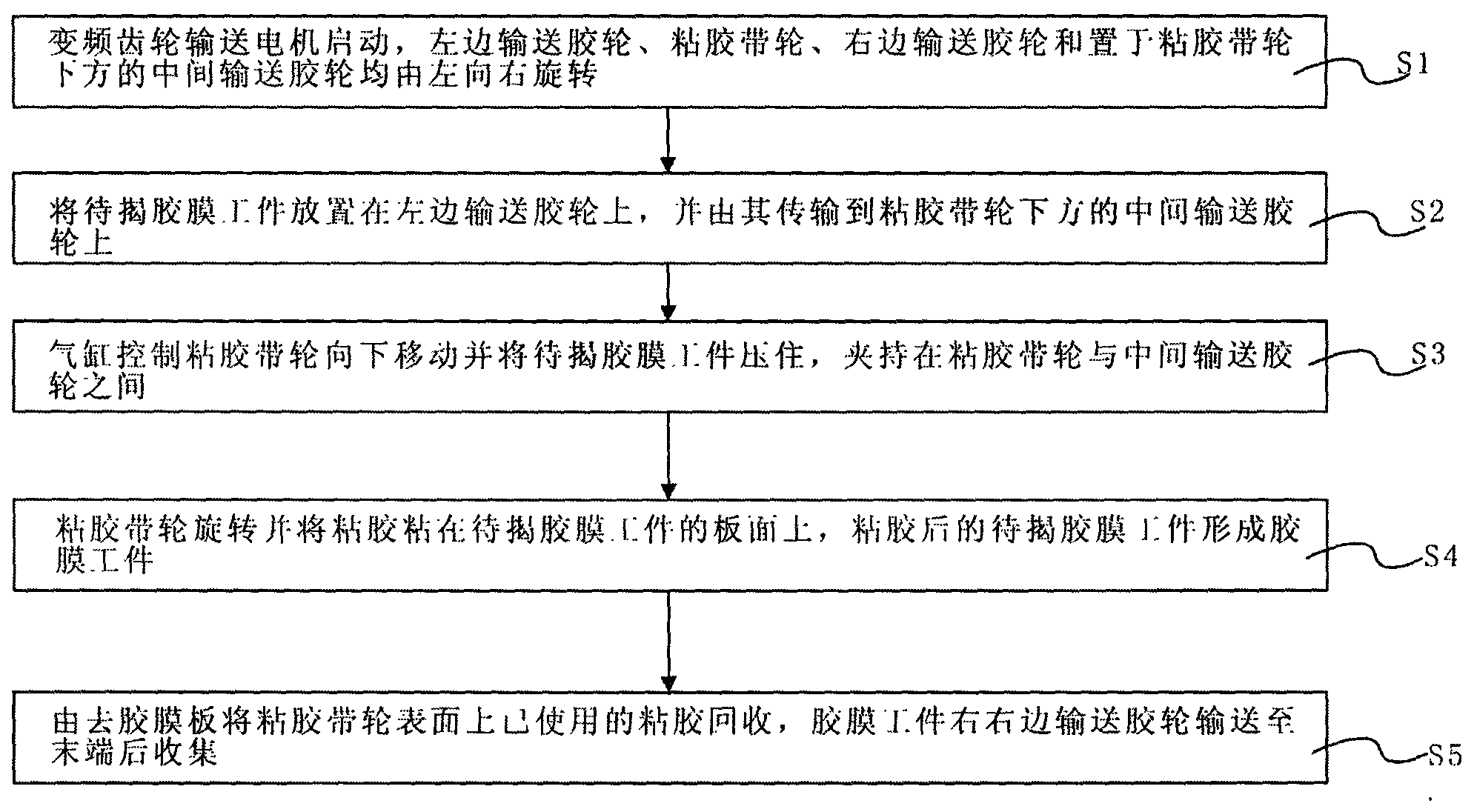

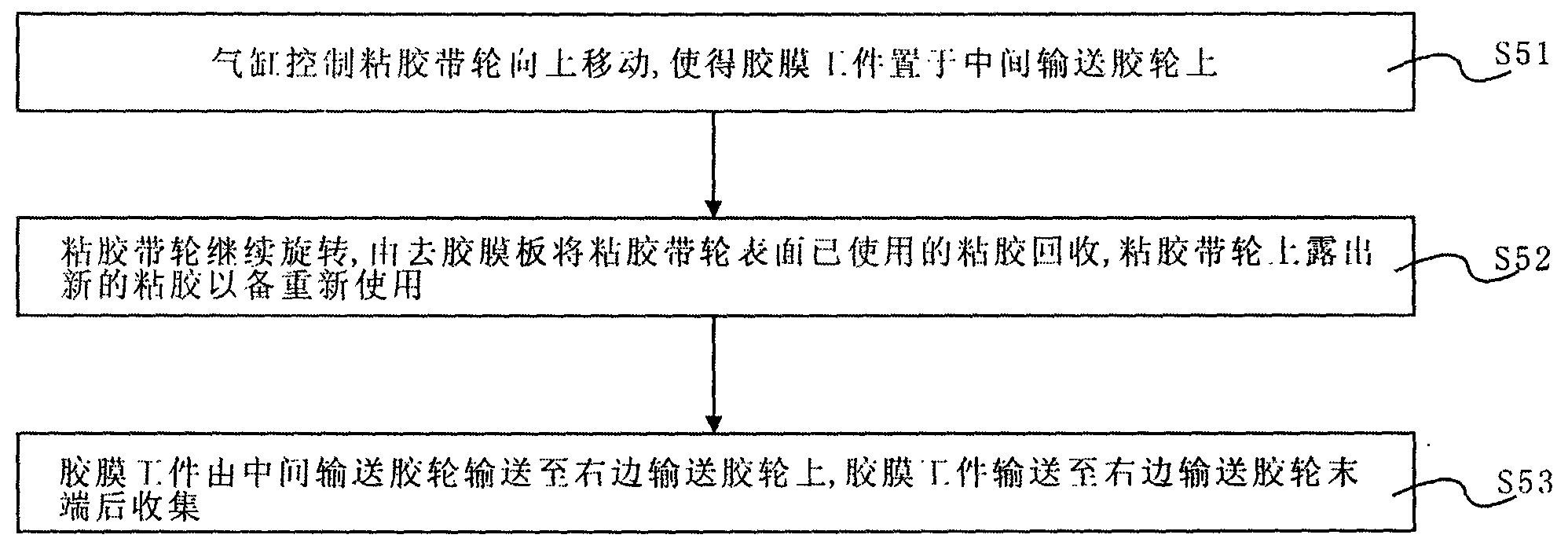

[0037] see figure 1 , the automatic glue-removing equipment of the present invention comprises frame 10, left conveying rubber wheel group 11, adhesive tape wheel 12, right conveying rubber wheel group 13, middle conveying rubber wheel placed below adhesive tape wheel 12, cylinder 14 , frequency conversion gear conveying motor 15 and glue-removing film plate 16; Inside, the frequency conversion gear conveying motor 15 is installed on the frame 10 and is driven and connected with the left conveying rubber wheel group 11, the adhesive belt wheel 12, the right conveying rubber wheel group 13 and the middle conveying rubber wheel through the conveying gear 17 respectively, and the glue is removed. The film plate 16 is placed on the right side of the adhesive belt wheel 12, and the adhesive film plate 16 can also be p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com