Junked tire steel wire taking device for regenerated rubber production and using method

A technology for waste tires and reclaimed rubber, which is applied to the field of scrap tires and steel wire devices for reclaimed rubber production, can solve the problems of low efficiency and low quality, and achieve the effects of uniform cutting, convenient operation and convenient cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

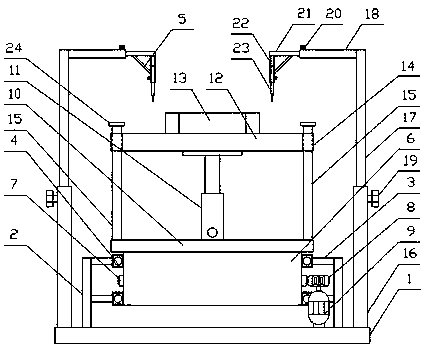

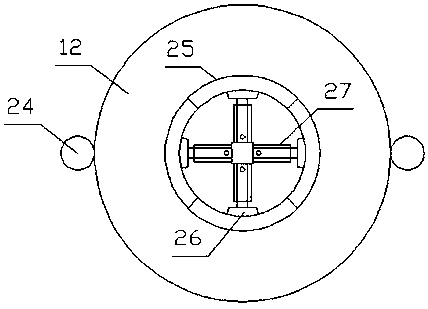

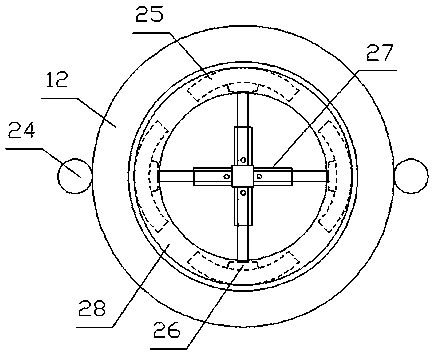

[0030] like Figure 1 to Figure 3 It shows a device for taking steel wire from waste tires used in the production of regenerated rubber according to the present invention, which includes a bottom plate and a support seat, and the side wall of the support seat 6 is provided with two horizontal bearings 4 and a first gear 7, the horizontal bearing and the first horizontal support rod 3 one end is connected, the other end of the first horizontal support rod is connected to the upper end of the first vertical support rod 2, the lower end of the first vertical support plate is connected to the bottom plate 1, and the first gear is provided with a second gear 8 that cooperates with each other, The second gear is connected to the motor 9, the top of the support seat is connected to the first support plate 10, the center of the first support plate is provided with a first cylinder 11, the lower end of the first cylinder is connected to the first support plate, the upper end of the firs...

Embodiment 2

[0036] A method for using a waste tire steel wire extraction device for regenerated rubber production, characterized in that it comprises the following steps:

[0037] 1) Put away the first cylinder first, and then put the waste tire on the tire fixing device;

[0038] 2) Then, the support ring is supported outward by the second cylinder, so that the support ring is closely connected with the inner wall of the tire;

[0039] 3) Then push the second support plate upwards through the first cylinder to make the cutting knife landslide on the tire surface;

[0040] 4), and then the support base is rotated by the motor to complete the cutting process;

[0041] 5) After finishing cutting one side, put away the first cylinder and the second cylinder, and change to the other side for cutting.

[0042] Specific usage and working principle:

[0043] like Figure 1 to Figure 3 As shown, when the waste tire 28 needs to be cut, the first cylinder is put away first, then the waste tire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com