Numerical control machine tool

A technology of CNC machine tool and clamping mechanism, which is applied in the direction of metal processing machinery parts, clamping, support, etc. It can solve the problems of equipment operators' safety risks, workpiece overheating and scrapping, equipment failure, etc., and achieve stable and smooth tool change action. Effects of improving work safety and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with specific embodiment and accompanying drawing, the present invention will be further described:

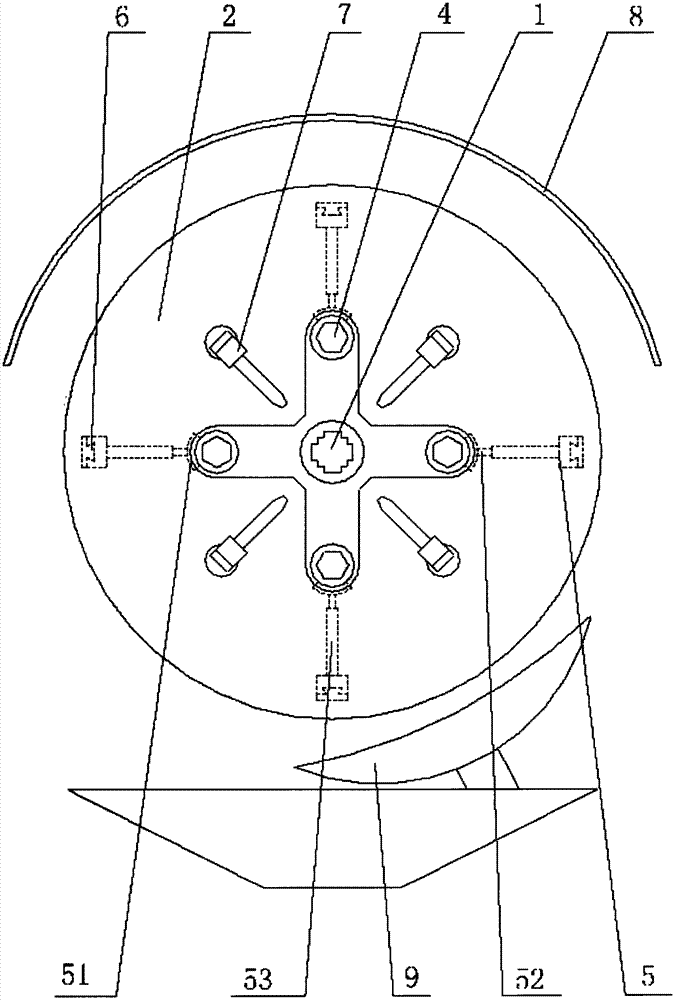

[0018] Refer to attached figure 1 As shown, the CNC machine tool of the present invention includes a workpiece clamping mechanism and a tool clamping mechanism, the workpiece clamping mechanism is provided with a feed drive mechanism, the tool clamping mechanism is provided with a displacement drive mechanism, and the tool clamping mechanism includes a positioning shaft 1, The tool disc 2 is set on the positioning shaft 1, and the tool disc 2 has at least two tool movable grooves 3, and the tool 4 is arranged in the tool movable groove along the axial direction of the tool disc; the positioning axis 1 is located at the center of the tool disc 2, and the tool moves One end of the slot 3 extends to the other end of the positioning shaft and extends radially toward the outer edge of the tool disc. The tool movable slot 3 has a tool pushing mechanism 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com