Meshing-telescopic-type telescopic drilling rod assembly

A telescopic drill pipe and telescopic type technology, which is applied in the field of drill pipe and meshing telescopic telescopic drill pipe assembly, can solve the problem that the length of the drill pipe cannot be adjusted in real time, and achieve stable and reliable drilling process, stable adjustment of the telescopic process, and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

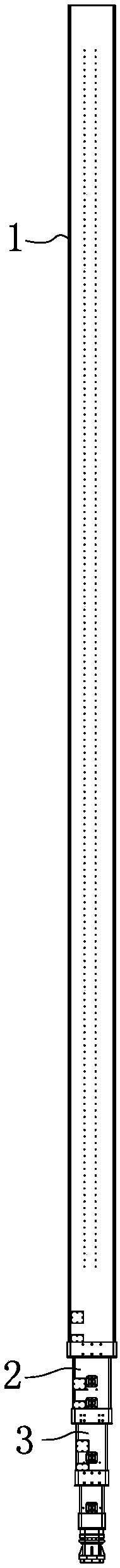

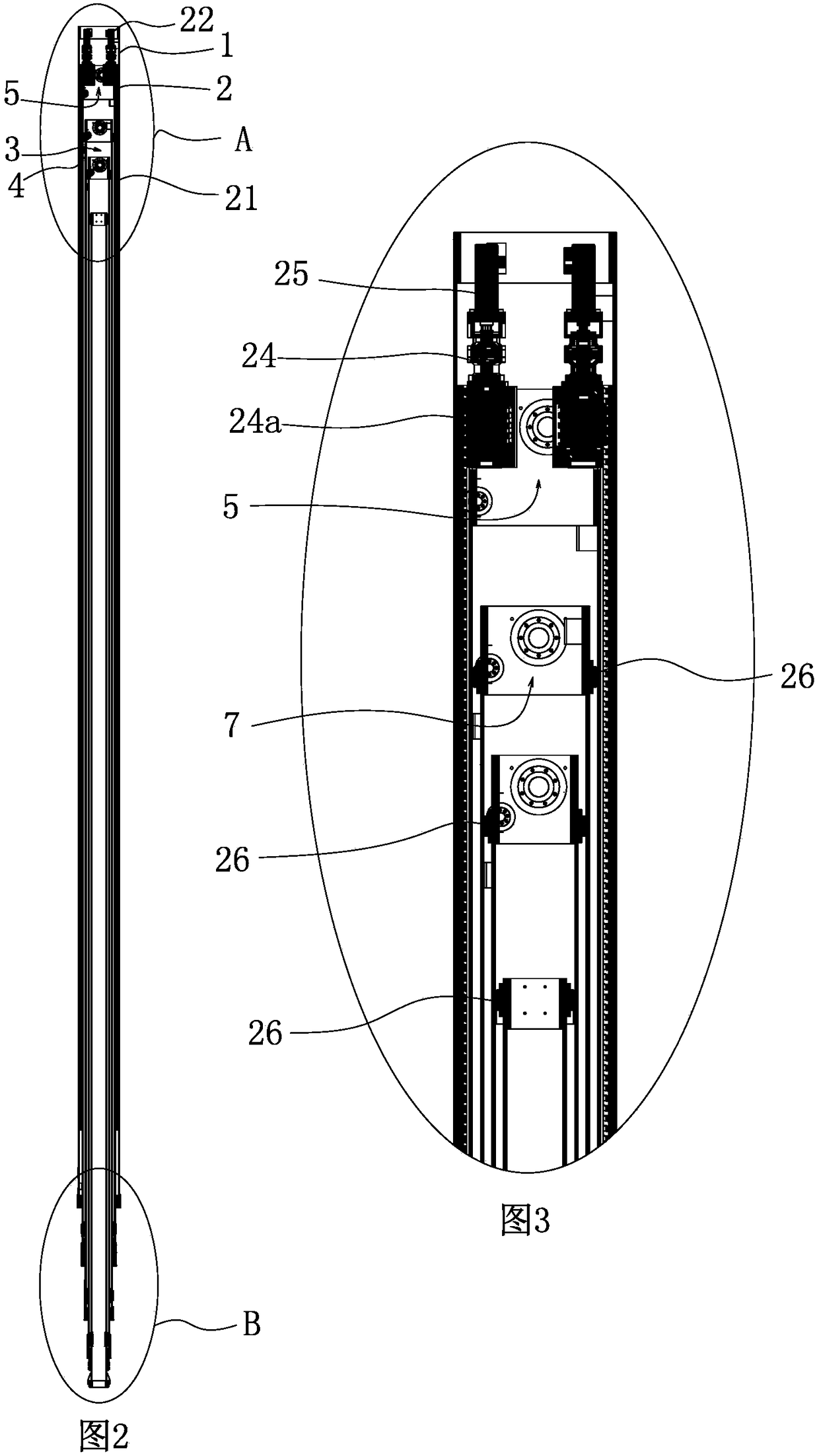

[0032] Such as figure 1 , figure 2 and image 3 As shown, a meshing telescopic telescopic drill rod assembly includes the outermost outer drill rod 1, the inner sleeve of the outer drill rod 1 is provided with an inner wall that engages with the inner wall of the outer drill rod 1 and can move up and down along the axial direction of the outer drill rod 1. Moving power drive rod 2. The meshing referred to in this embodiment is preferably the meshing of the rotating screw thread. The meshing method can ensure that the power driving rod 2 is closely combined with the external drill pipe 1 without gaps, and when the power driving rod 2 moves up and down, it can be stable. The effect of exercise.

[0033] Those skilled in the art should understand that the power drive rod 2 can also adopt a top screw structure, and threads are provided on the inner wall of the external drill rod 1, so as to realize the telescopic movement up and down.

[0034]In a preferred solution, in order...

Embodiment 2

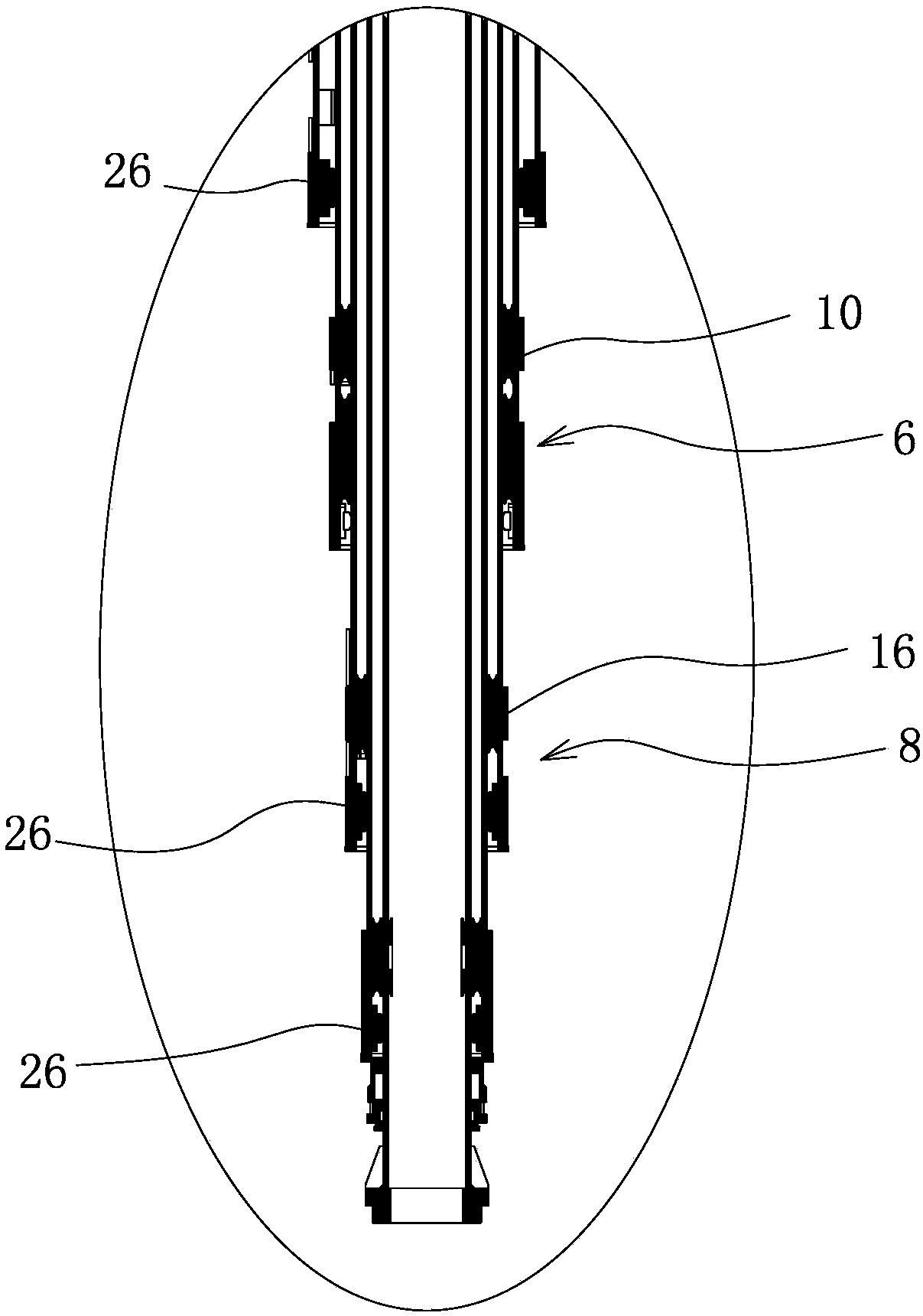

[0048] The structure and working principle of this embodiment are the same as that of Embodiment 1, the difference is that in combination Figure 6 and Figure 7 As shown, the telescopic extension rod assembly 3 includes several extension rods 4 that are nested with each other. Except for the extension rod 4 located in the innermost part, the upper and lower ends of the remaining extension rods 4 are respectively provided with an upper lifting follower pulley assembly 7 and a lower pressing pulley assembly 7. The follower pulley assembly 8, wherein the lifting follower pulley assembly 7 located on the outermost extension rod 4 of the telescopic extension rod assembly 3 is wound with a steel wire rope, and one end of the wire rope is connected and sleeved in the extension rod 4 and connected to the extension rod 4. The top of another extension bar 4 adjacent to it, the other end is connected to the bottom of the power drive bar 2, a steel wire rope is wound on the pressing foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com