Straight-flow steam generator pressure control method and system

A steam generator and pressure control technology, which is applied in the field of nuclear power, can solve the problems of mismatching, high requirements, unfavorable system stability, etc. without taking into account the rapid response characteristics of once-through steam generators, reactor core response lag, etc., to achieve response and The action of the actuator is reasonable, which is conducive to the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

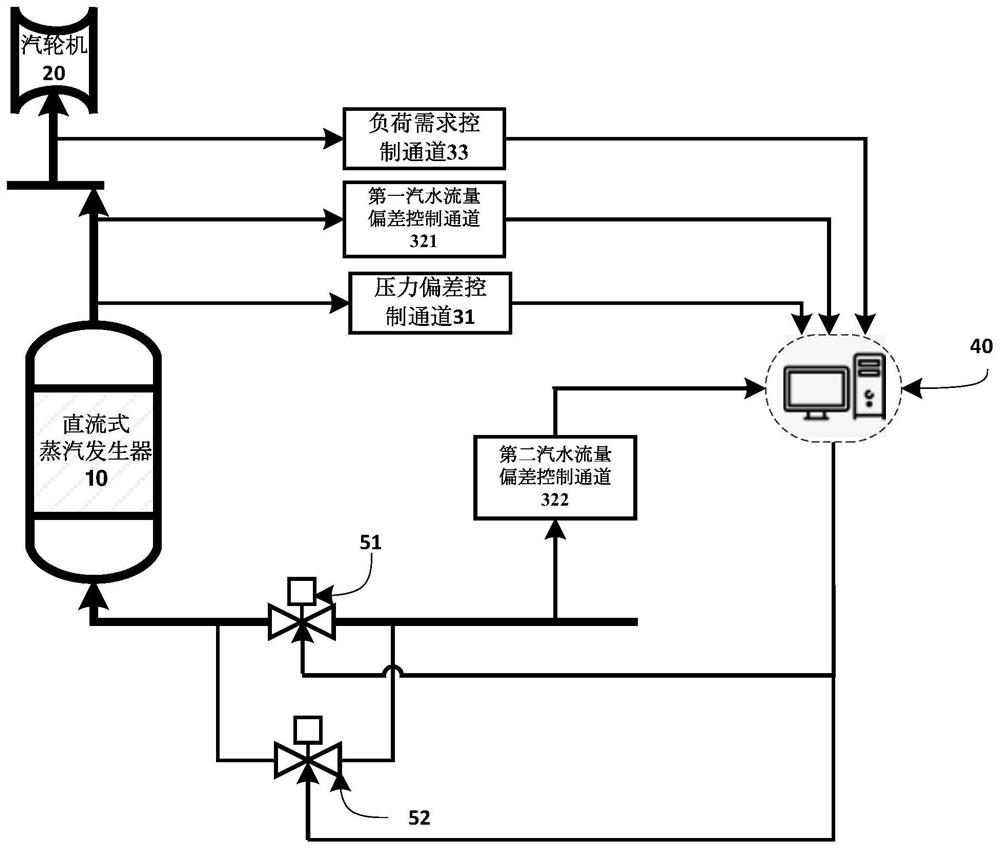

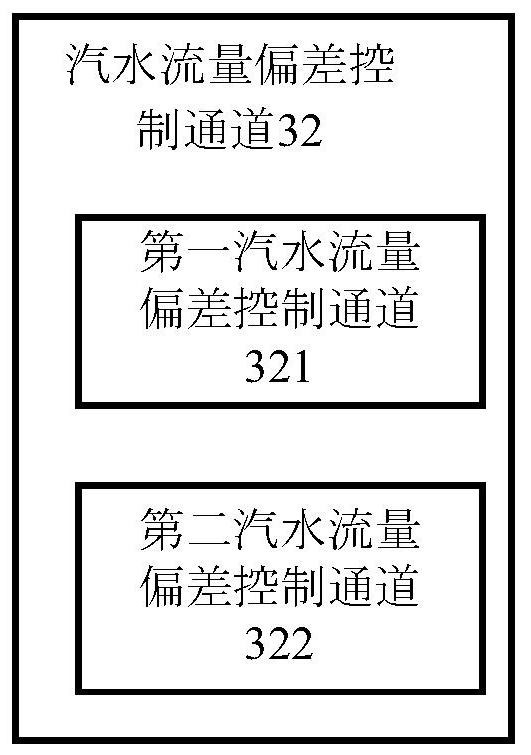

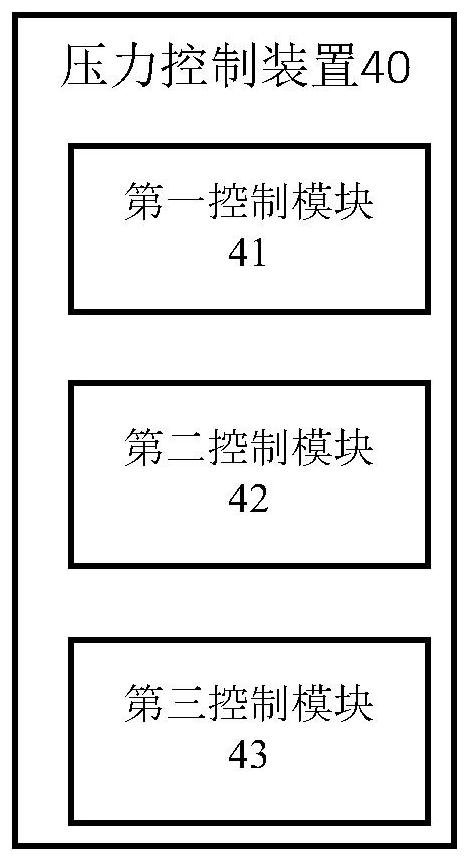

[0036] figure 1 It shows that the once-through steam generator pressure control system in some embodiments of the present invention is used to control the once-through steam generator 10, which can meet the fine adjustment of the pressure in the transient process of small disturbances, and can also be used in large-scale During transient changes, quickly and stably adjust to the target state. combine Figure 1-4 As shown, the once-through steam generator pressure control system in the embodiment of the present invention includes a once-through steam generator 10, a steam turbine 20, a feed water regulating valve group 50, a pressure deviation control channel 31, a steam-water flow deviation control channel 32, and a lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com