Horizontal filling packaging machine capable of effectively reducing occupied space

A technology of occupying space and packaging machines, applied in the field of horizontal filling and packaging machines, can solve the problems of occupying a large space and increasing production costs of producers, and achieve the effects of reducing the space occupied, improving work efficiency and simple equipment structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

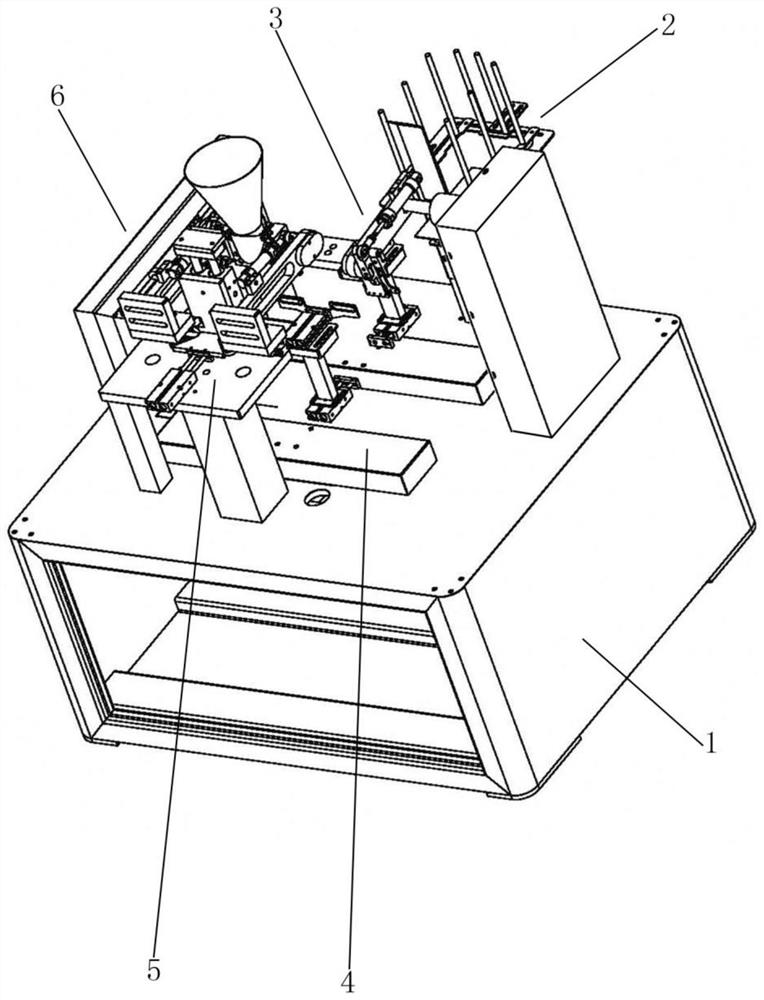

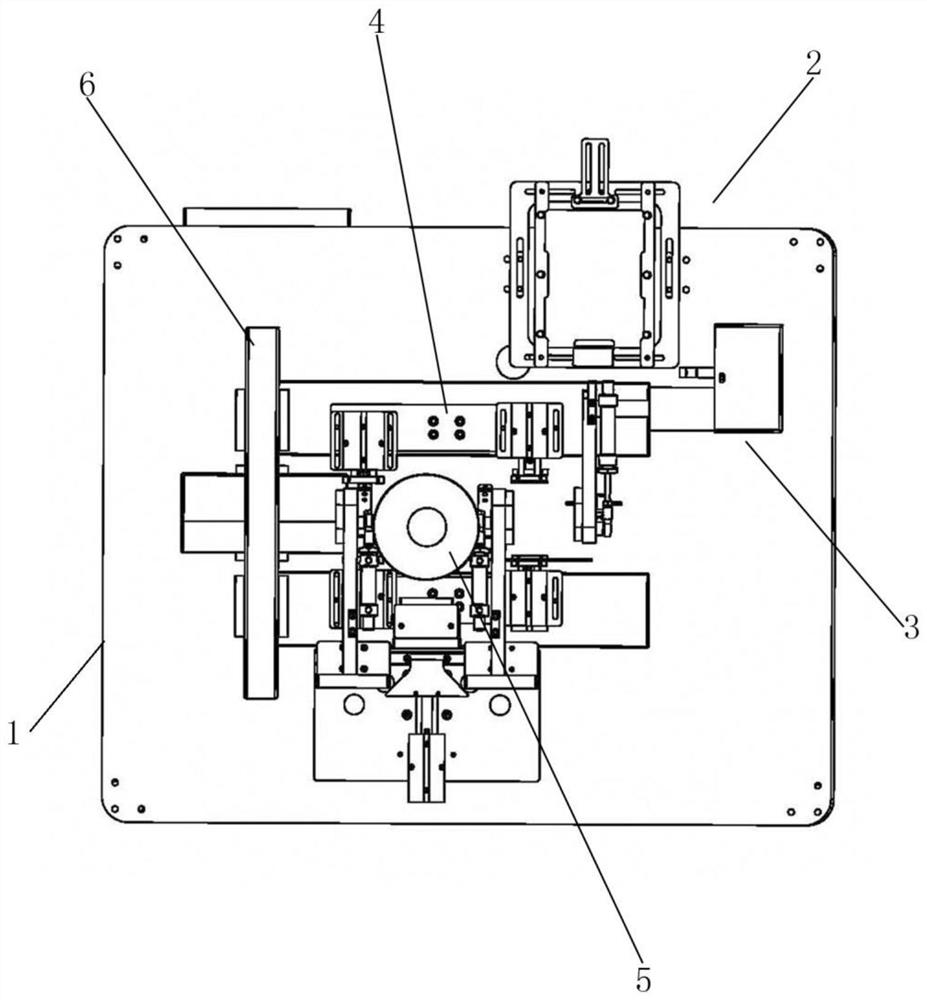

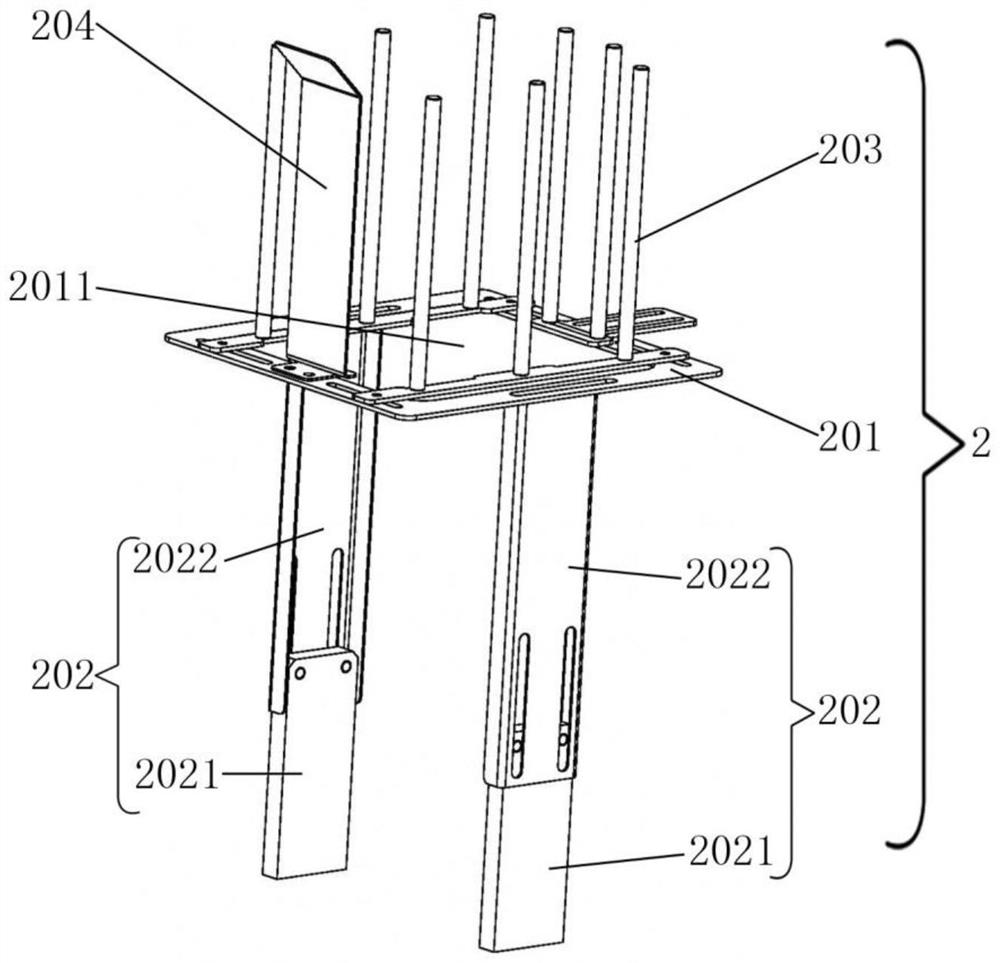

[0034] Such as Figure 1-12As shown, the horizontal filling and packaging machine in this embodiment that can effectively reduce the floor space includes a machine platform 1, a packaging bag storage rack 2, a bag taking mechanism 3, a packaging bag transfer device 4, a filling mechanism 5, and a sealing mechanism 6 , The top surface of the machine table 1 is provided with two chutes 101 and is provided with a finished product delivery trough 102 .

[0035] The packaging bag storage rack 2, the bag taking mechanism 3, the packaging bag transfer device 4, the filling mechanism 5, and the sealing mechanism 6 are respectively installed on the top surface of the machine 1, and the packaging bag storage rack 2 is located on the right side of the machine 1 At the rear end, the bag taking mechanism 3 is located on the right side of the machine 1 and in front of the packaging bag storage rack 2, the packaging bag transfer device 4 is located in the middle of the machine 1 and moves le...

Embodiment 2

[0064] The difference between this embodiment and embodiment 1 is:

[0065] Vacuum suction cups are respectively installed on all the third bag clipping pieces 4022 , the first bag clipping pieces 40112 , and the second bag clipping pieces 40122 of the packaging bag transfer device 4 , and each vacuum suction cups are respectively connected to external vacuum pumps. This enables better clamping of the packaging bag 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com