Four-DOF (degree of freedom) parallel sorting robot

A technology of robot and degree of freedom, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of large space occupied by DELTA robots and heavy structure of SCARA robots, and achieve the effect of small space occupation, simple structure, and simple installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

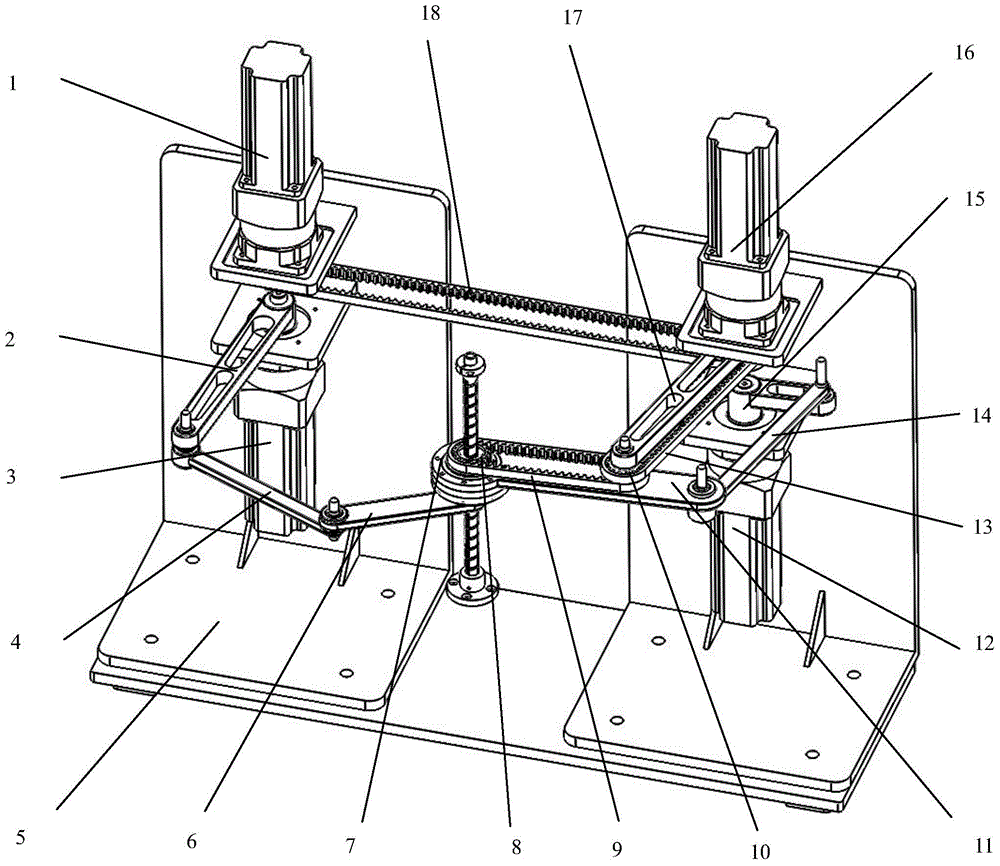

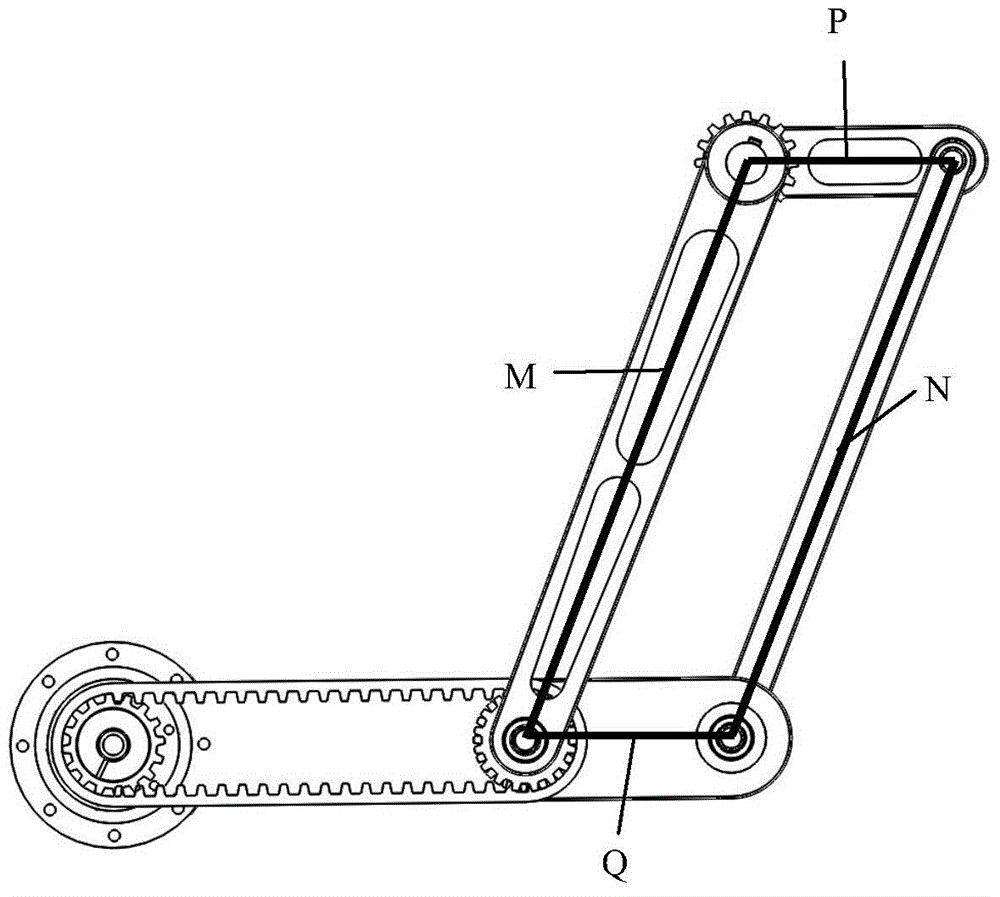

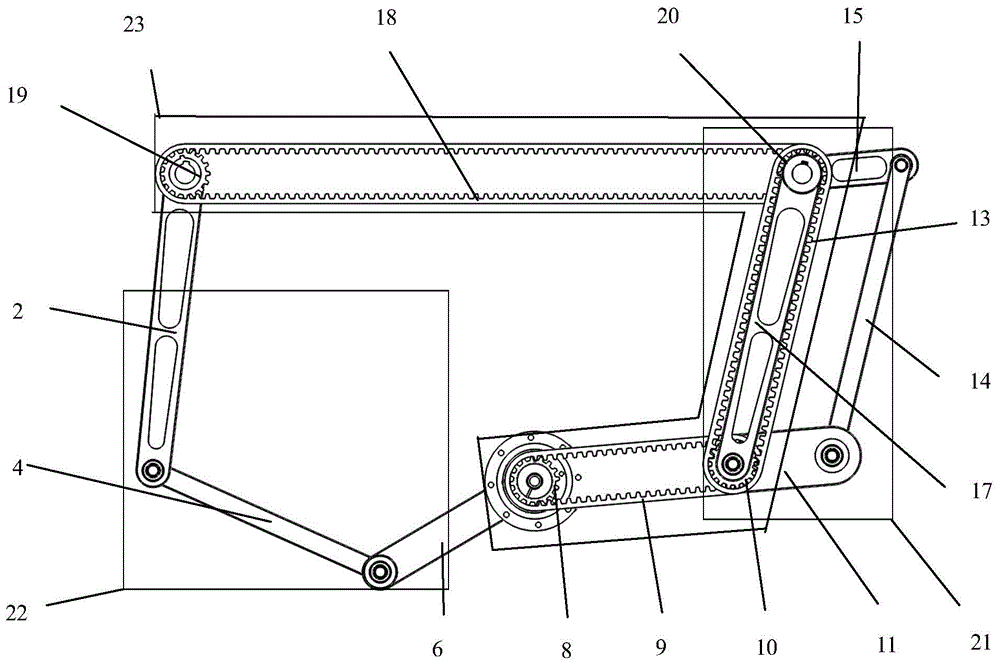

[0025] A four-degree-of-freedom parallel sorting robot provided by the present invention includes a frame 5 , a driving device, three motion branch chains and an end effector 7 . The end effector 7 forms a closed-loop parallel structure with the frame 5 through the kinematic branch chain; the kinematic branch chain includes a first branch chain 21, a second branch chain 22, a synchronous belt branch chain 23, and the first branch chain 23. A branch chain 21 includes a first branch chain and a second branch chain; the first branch chain 21 serves as a moving platform for the end effector 7, providing it with two plane degrees of freedom in the X and Y directions; The two branch chains 22 provide the end effector 7 with a rotational degree of freedom around the Z axis; the synchronous belt branch chain 23 transmits torque to the end effector 7 through the synchronous belt, providing it with a plane degree of freedom in the Z direction; The end effector 7 is composed of a lead sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com