Aluminum pan

An aluminum pot and aluminum technology, applied in the field of tableware and pots, can solve the problems of personal injuries caused by hot objects in the pot, convex and concave deformation of the bottom surface of the pot, etc., achieve good heating effect, increase the thickness of the heating layer, eliminate The effect of thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0060] Implementation Example 1

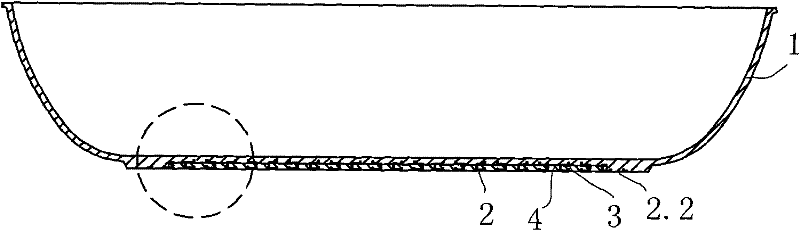

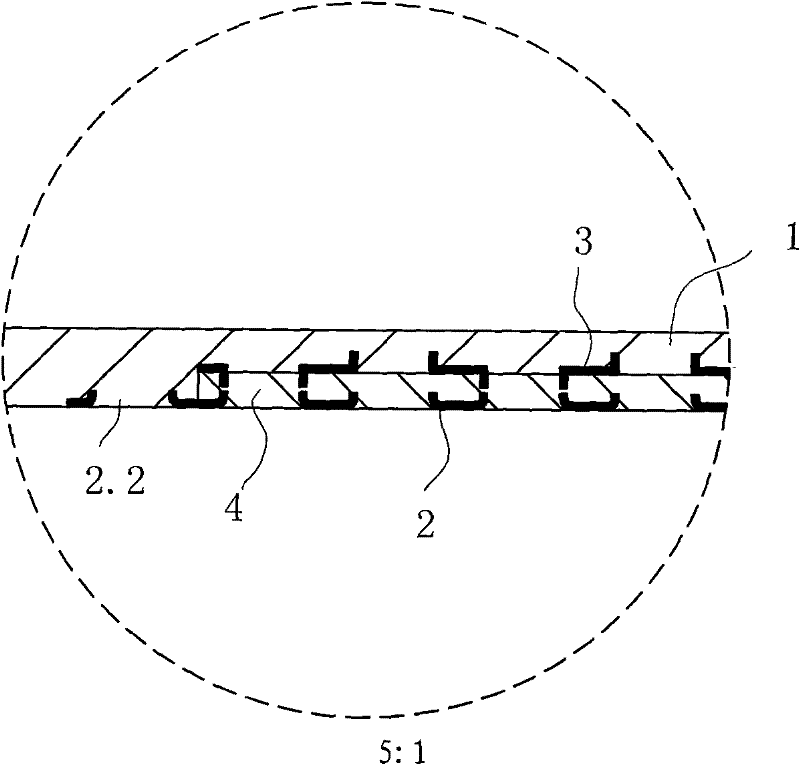

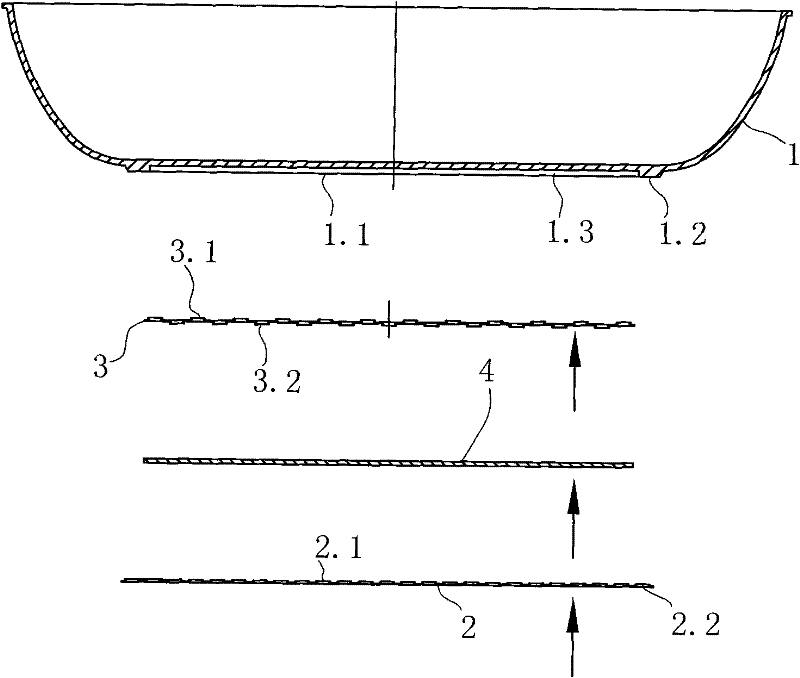

[0061] Such as Figure 1-3 The key point of the invention of the shown aluminum pot is that the lower surface 1.1 of the bottom of the pot body 1 is a surface for compounding, and is provided with an accommodating groove 1.3 whose shape and thickness are adapted, usually circular or Square; there is another metal connecting plate 3, the surface of which is distributed with upward turning holes 3.1 and downward turning holes 3.2, the size and shape of which are matched with the shape of the accommodating tank 1.3, which can be round or square, and turning holes 3.1 and the downturning hole 3.2 are circular, square, pentagonal or hexagonal, the upturning hole 3.1 and the downturning hole 3.2 are distributed at intervals, and can be arranged in concentric rings. The metal connecting plate 3 is made of stainless ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com