Hydraulic control type reaming tool during drilling

A technology of reaming while drilling and hydraulic control, applied in drilling equipment, earthwork drilling, drilling equipment and methods, etc., can solve problems such as borehole shrinkage, achieve effective control, solve borehole shrinkage and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

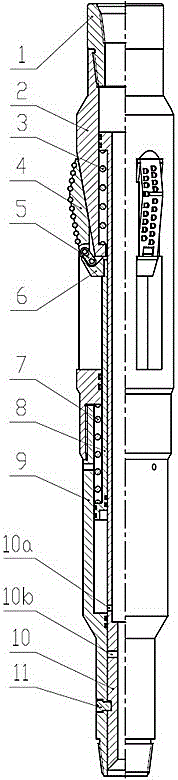

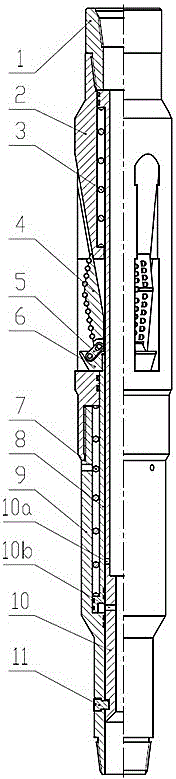

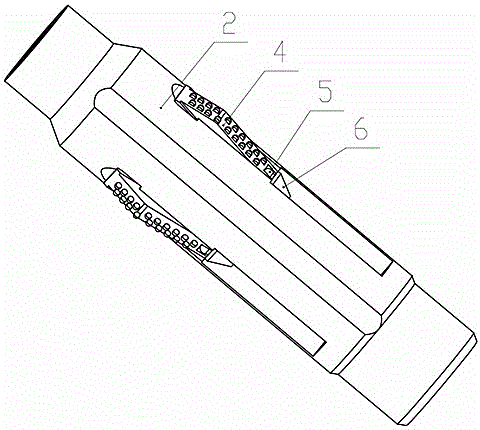

[0013] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a kind of hydraulic control type reaming tool while drilling in the present invention is composed of an upper joint 1, an upper cylinder body 2, an upper spring 3, a reaming blade 4, a connecting rod 5, a blade seat 6, a lower spring 7, The piston cylinder 8, the lower cylinder body 9, the center pipe 10 and the sliding pin 11 are composed; its structural features are: the upper end of the upper joint 1 is connected with the upper drill string screw, and the lower end of the lower cylinder 9 is connected with the lower drill string screw; the upper cylinder Three grooves are evenly arranged in the middle of the body 2 in the circumferential direction, the lower part of the groove is connected to the inner and outer spaces of the upper cylinder 2, the upper part of the groove is set as a slope, grooves are arranged on both sides of the slope, and a circle is set in the middle of the inner cavity of the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com