Double-layer fried bread stick machine and method of making fried bread sticks

A deep-fried dough stick machine, double-layer technology, applied in the direction of oil/fat baking, dough forming machinery or equipment, baking, etc., can solve the problems of danger, insufficient automation, and warped ends of fried dough sticks, etc., and achieve a high degree of automation , good starting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

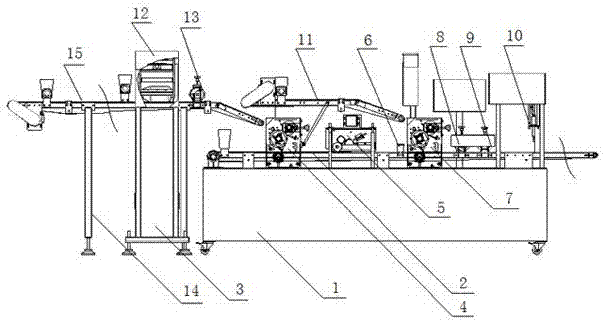

[0019] Such as figure 1 As shown, a double-layer dough stick machine includes a frame 1 and a conveyor belt 2 installed on the frame, a front entry mechanism 3 located at the feeding end of the conveyor belt 2, and arranged in order from the feeding end to the outlet end. The first pressing mechanism 4, the oil brushing mechanism 5, the water brushing mechanism 6, the second pressing mechanism 7, the circular cutter mechanism 8, the middle pressure roller mechanism 9, the cutting table mechanism 10, and the rear entry mechanism 11 is located on the conveyor belt 2, and the output end of the back noodle mechanism 11 is located at the input end of the second noodle pressing mechanism 7; the front noodle mechanism 3 is provided with at least a noodle rolling mechanism 12 and a three-round knife mechanism 13.

[0020] The front entry mechanism 3 includes a front entry frame 14 and a front conveyor belt 15 installed on the front entry frame. The front conveyor belt 15 is driven by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com