Special-purpose multifunctional modified random polypropylene material for pipe and its preparing process and application

A technology for polypropylene pipes and special materials, applied in the field of plastic materials, can solve problems such as low notched impact strength, poor low-temperature notched impact performance, and impact performance that cannot meet the requirements, and achieve excellent thermal stability and high heat resistance , to solve the effect of large shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

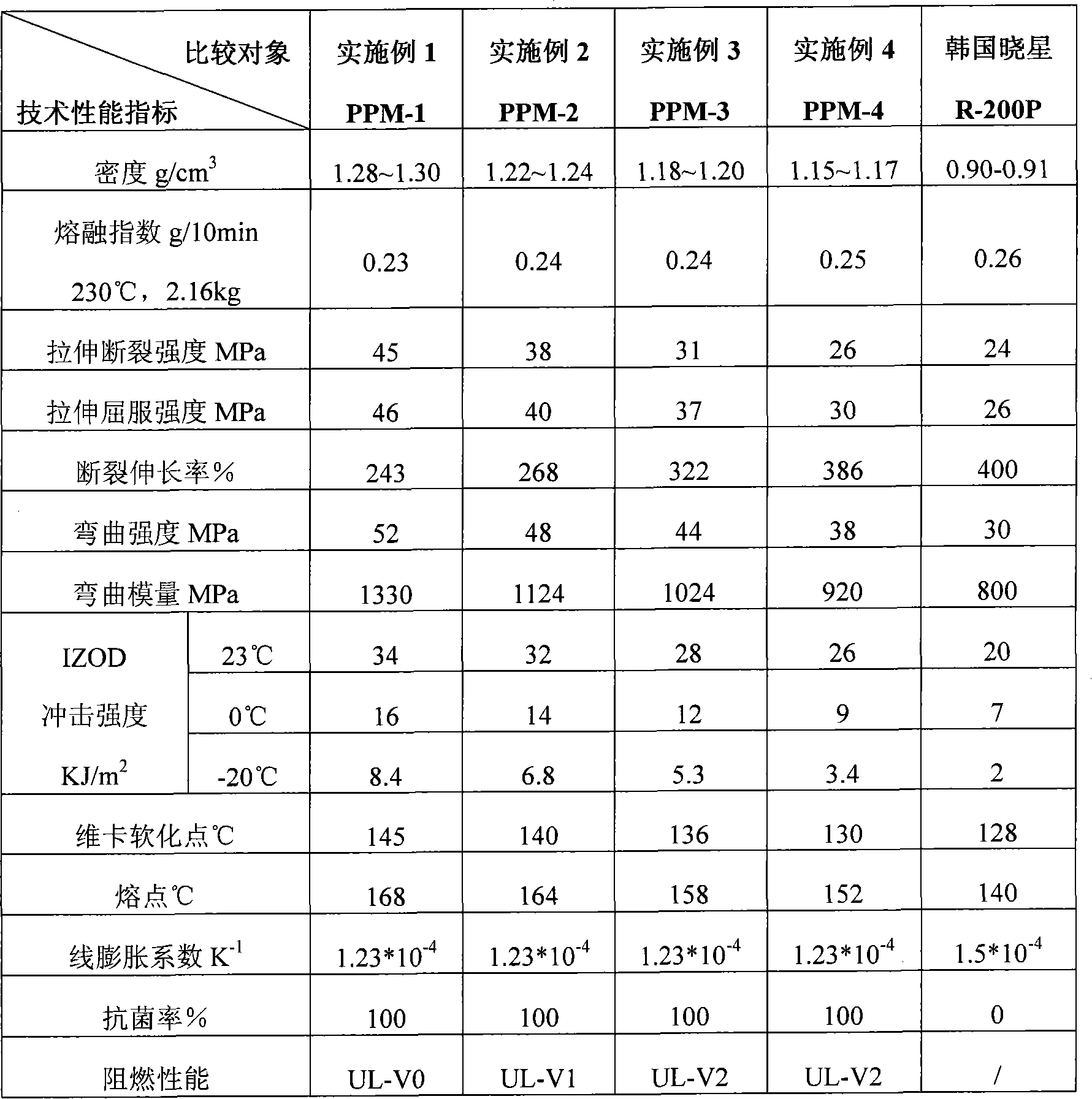

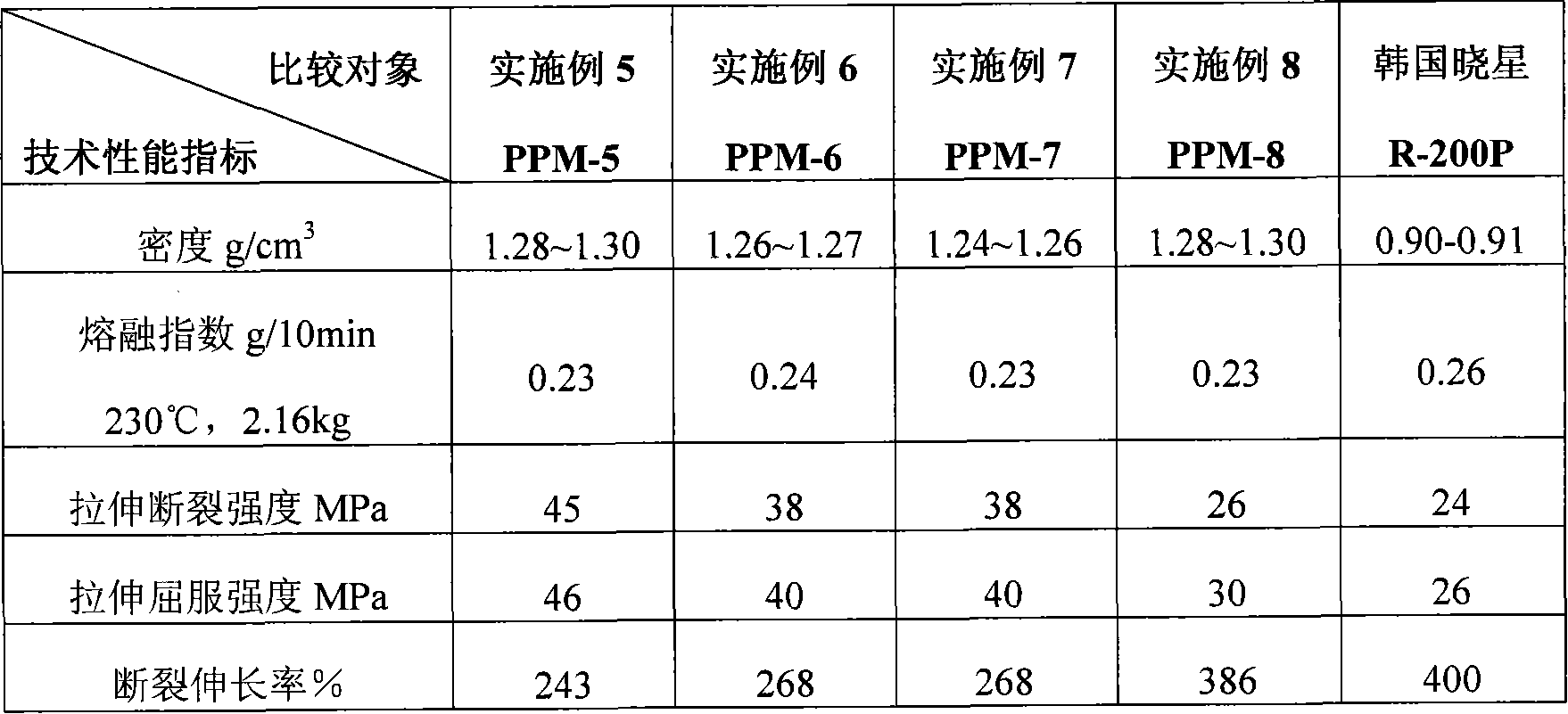

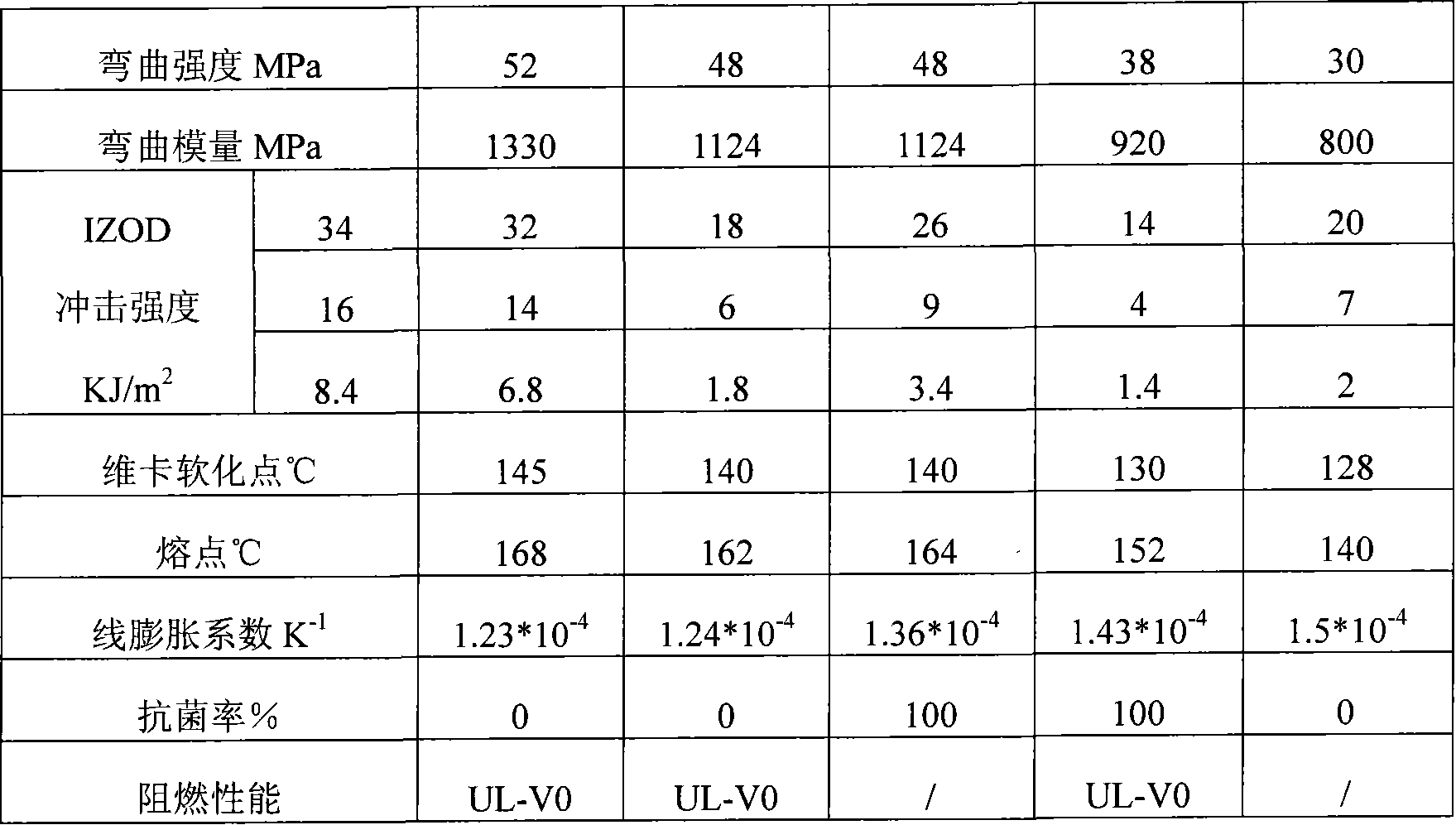

Examples

Embodiment 1

[0043] Random copolymerized polypropylene (MFR=0.3g / 10min) 50 parts

[0044] Environmental Flame Retardant

[0045] (50 parts TDE, 30 parts PBDE and 20 parts Sb 2 o 3 ) 15 copies

[0046] Inorganic filler pre-dispersed masterbatch (HCT-1) 25 parts

[0047] Impact modifier POE-g-MA 10 parts

[0048] Antioxidant 1010 0.3 parts

[0049] Composite antibacterial masterbatch EMB-1 3 parts

[0050] Polyester type hyperdispersant 1 part

[0051] The preparation method of the special material for multifunctional modified random copolymerized polypropylene pipes comprises the following steps:

[0052](1) In a 200L high-speed mixer, mix 25 parts of nano-calcium carbonate (30-65 nanometers in particle size), 10 parts of talcum powder (Liaoning Dongchen 1250 mesh) and heavy calcium carbonate according to the formula ratio in Table 1. (Particle size is 6-10 micron) 50 parts, stirring at 400r / min speed, then add 0.5 parts of silane coupling agent (KH-550), 3 parts of macromolecular c...

Embodiment 2

[0057] Random copolymerized polypropylene (MFR=0.6g / 10min) 60 parts

[0058] Environmental Flame Retardant

[0059] (30 parts TDE, 30 parts PBDE and 10 parts Sb 2 o 3 ) 10 copies

[0060] Inorganic filler pre-dispersed masterbatch (HCT-1) 20 parts

[0061] Impact modifier (CPE) 10 parts

[0062] Antioxidant 1098 0.2 parts

[0063] Composite antibacterial masterbatch EMB-1 2 parts

[0064] 1 part polypropylene wax

[0065] (1) In a 200L high-speed mixer, mix 25 parts of nano-calcium carbonate (30-65 nanometers in particle size), 10 parts of talcum powder (Liaoning Dongchen 1250 mesh) and heavy calcium carbonate according to the formula ratio in Table 1. (particle size of 6-10 microns) 50 parts, stirred at a speed of 400r / min, and then sequentially added 0.5 parts of silane coupling agent, 3 parts of macromolecule compatibilizer PP-g-AA and homopolypropylene (melt Volume flow rate is 10g / 10min) 10 parts, after adding, stir with 1000r / min speed for 1 minute to obtain the ...

Embodiment 3

[0070] Random copolymerized polypropylene (MFR=0.4g / 10min) 70 parts

[0071] Environmental Flame Retardant

[0072] (40 parts TDE, 50 parts PBDE and 15 parts Sb 2 o 3 ) 5 copies

[0073] Inorganic filler pre-dispersed masterbatch (HCT-2) 15 parts

[0074] Impact modifier (POE-g-MA) 10 parts

[0075] Antioxidant (B-215) 0.1 parts

[0076] Composite antibacterial masterbatch EMB-2 3 parts

[0077] 3 parts silicone oil

[0078] (1) In a 200L high-speed mixer, mix 10 parts of nano-calcium carbonate (30-65 nanometers in particle size), 5 parts of talcum powder (Liaoning Dongchen 1250 mesh) and heavy calcium carbonate according to the formula ratio in Table 1. (Particle size is 6-10 microns) 75 parts, stir at 400r / min speed, then add 2 parts of aluminate coupling agent and 6 parts of macromolecular compatibilizer PP-g-MA and homopolypropylene (The melt flow rate is 8g / 10min) 5 parts, after the addition is completed, stir with 600r / min speed for 3 minutes to obtain the mixtur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com