Loose-soft rock soil stratum reverse circulation casing-following drilling tool and drilling process

A technology of follow-through drilling tools and reverse circulation, which is applied in earthwork drilling, percussion drilling, rotary drilling, etc., can solve the problems of unstable reverse circulation formation, difficult processing, complex structure, etc., and achieve high drilling efficiency. Chip transport efficiency, high connection strength, and the effect of preventing hole wall collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. It should be understood by those skilled in the art. The content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

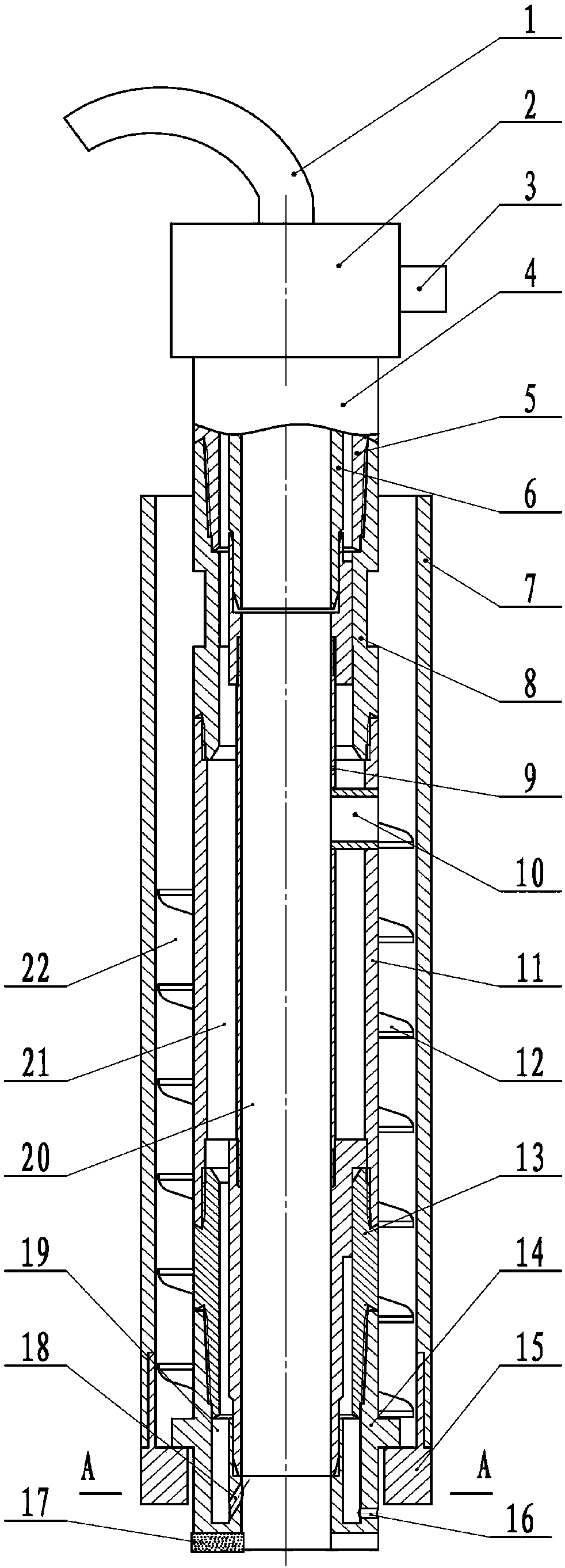

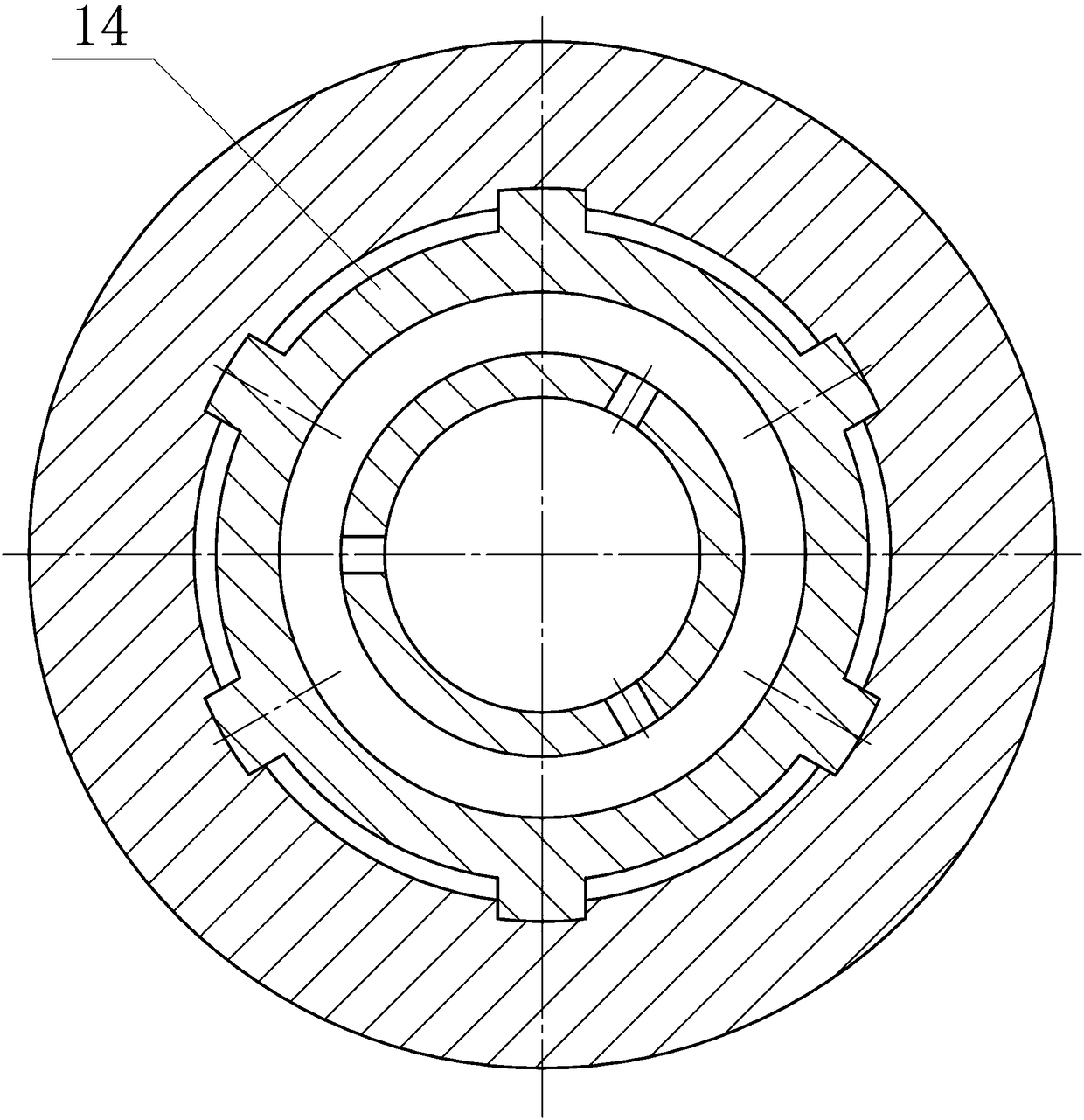

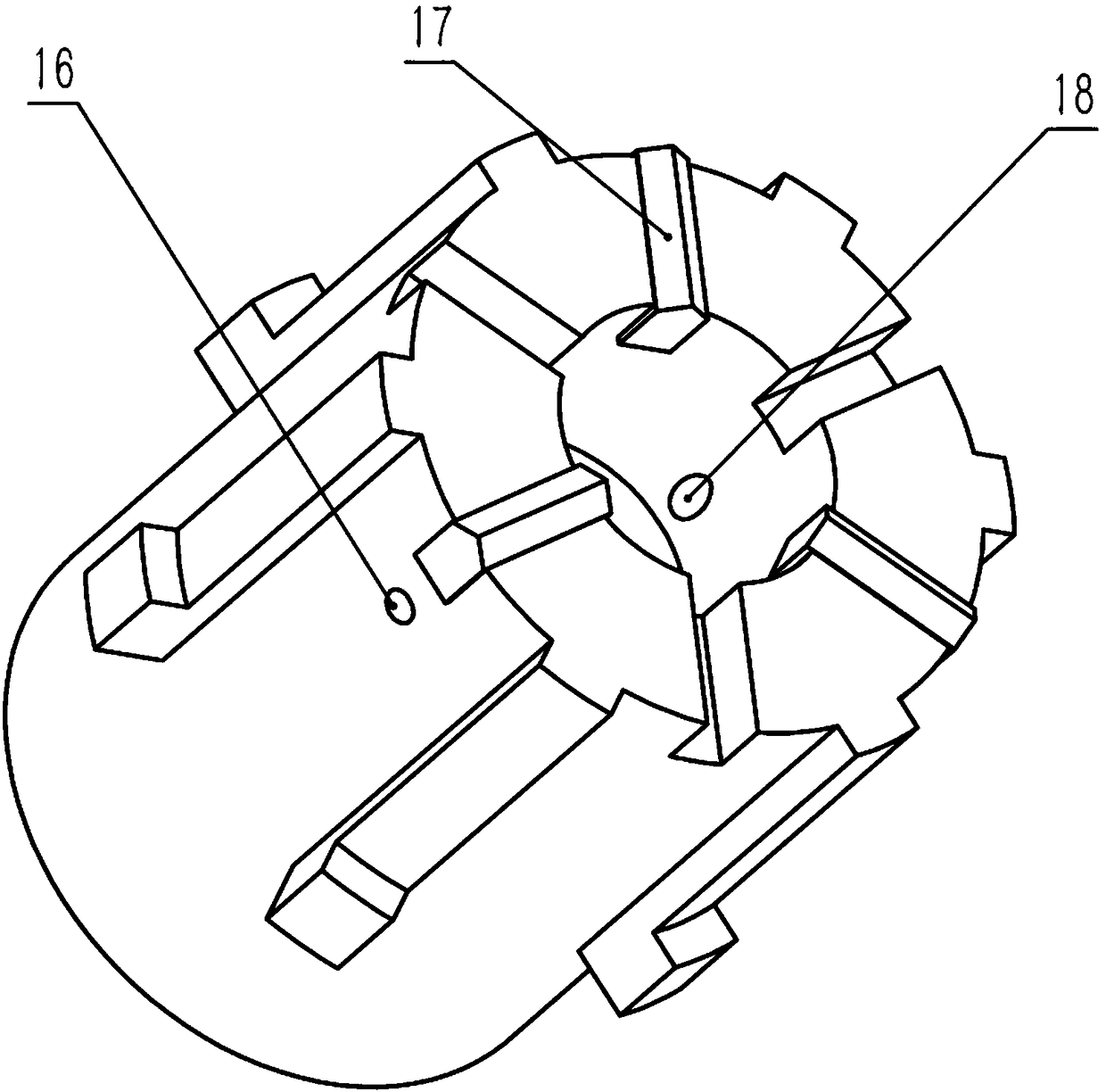

[0033] like figure 1 As shown, the reverse circulation heel pipe drilling tool in soft rock soil is a coaxial three-channel structure, including a double-walled drill pipe 4, an auger drill pipe 12, a drill bit 14, a casing 7 and a pipe shoe 15, and the double-walled drill pipe 4 consists of a double-walled drill pipe The outer pipe 5 of the double-wall drill pipe and the inner pipe 6 of the double-wall drill pipe form an annular gap between the outer pipe 5 of the double-wall drill pipe and the inner pipe 6 of the double-wall drill pipe. 12 includes a coaxially arranged auger rod inner t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com