Foam concrete and preparation method thereof

A technology of foam concrete and foaming additives, which is applied in the field of building materials, can solve problems such as wall panel cracking, large drying shrinkage, and quality impact, and achieve the effects of increasing toughness, strong water resistance, and increasing structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

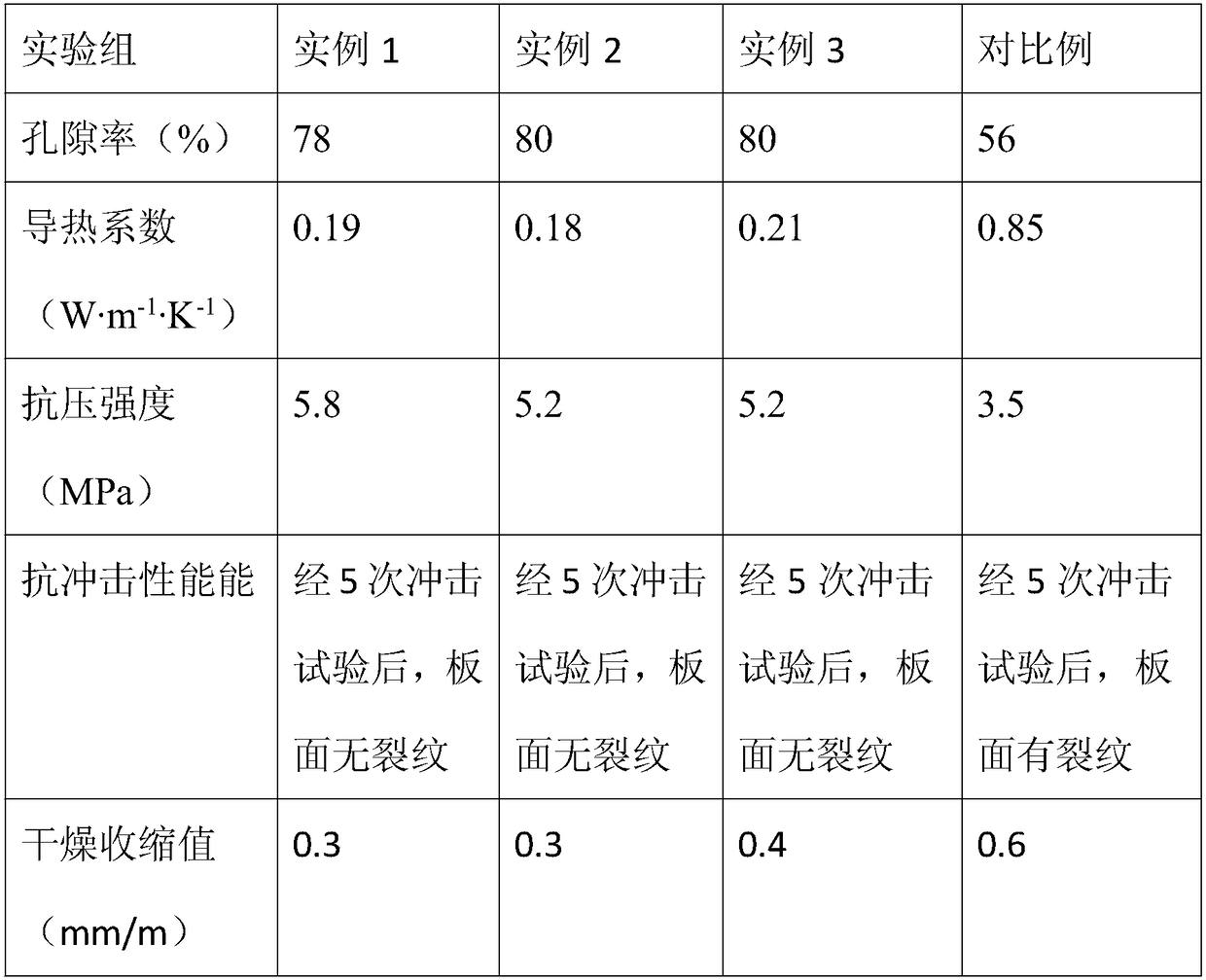

Examples

example 1

[0035] Step 1: Prepare anti-cracking fiber expansion agent

[0036] (1) Select the straw, pulverize it and put it into the carbonization machine for carbonization to carbonize the straw;

[0037] (2) In terms of parts by weight, 10 parts of calcium aluminate clinker, 10 parts of carbonized straw, 1 part of magnesium oxide, 1 part of calcium oxide, 4 parts of basalt fiber and 3 parts of waste rock wool were selected respectively, and added to the pulverizer for crushing , After being crushed, an anti-cracking fiber expansion agent is obtained.

[0038] Step 2: Ratio of foam concrete raw materials

[0039] In parts by weight, 70 parts of cement, 3 parts of perlite, 8 parts of attapulgite, 5 parts of anti-cracking fiber expansion agent, 3 parts of light calcium carbonate, 5 parts of activated sludge, 4 parts of natural latex, 0.1 parts of Part of foaming aid, 1 part of surfactant, 0.3 part of foam stabilizer and 30 parts of water.

[0040] The foaming aid is a mixture of azodi...

example 2

[0047] Step 1: Prepare anti-cracking fiber expansion agent

[0048] (1) Select the straw, pulverize it and put it into the carbonization machine for carbonization to carbonize the straw;

[0049] (2) In terms of parts by weight, respectively select 13 parts of calcium aluminate clinker, 13 parts of carbonized straw, 2 parts of magnesium oxide, 2 parts of calcium oxide, 5 parts of basalt fiber and 4 parts of waste rock wool, and add them to a pulverizer for pulverization. After being pulverized, an anti-cracking fiber expansion agent is obtained.

[0050]Step 2: Ratio of foam concrete raw materials

[0051] In parts by weight, 80 parts of cement, 4 parts of perlite, 9 parts of attapulgite, 6 parts of anti-cracking fiber expansion agent, 4 parts of light calcium carbonate, 7 parts of activated sludge, 5 parts of natural latex, 0.2 parts of Part foaming aid, 2 parts surfactant, 0.4 part foam stabilizer and 33 parts water.

[0052] The foaming aid is a mixture of azodicarbonami...

example 3

[0059] Step 1: Prepare anti-cracking fiber expansion agent

[0060] (1) Select the straw, pulverize it and put it into the carbonization machine for carbonization to carbonize the straw;

[0061] (2) In terms of parts by weight, respectively select 15 parts of calcium aluminate clinker, 15 parts of carbonized straw, 1 part of magnesium oxide, 1 part of calcium oxide, 4 parts of basalt fiber and 3 parts of waste rock wool, and add them to the pulverizer for crushing , After being crushed, an anti-cracking fiber expansion agent is obtained.

[0062] Step 2: Ratio of foam concrete raw materials

[0063] In parts by weight, 90 parts of cement, 5 parts of perlite, 10 parts of attapulgite, 5 parts of anti-cracking fiber expansion agent, 3 parts of light calcium carbonate, 5 parts of activated sludge, 4 parts of natural latex, 0.1 parts of activated sludge were selected respectively. Part of foaming aid, 1 part of surfactant, 0.3 part of foam stabilizer and 30 parts of water.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com