Processing and manufacturing method of novel double-state-structure titanium-based composite material

A titanium-based composite material, processing and manufacturing technology, applied in the field of processing and manufacturing of new dual-state titanium-based composite materials, can solve problems such as poor plasticity and mechanical properties, and achieve simplified thermal processing technology, high strength and fatigue performance, The effect of good tensile plasticity and fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

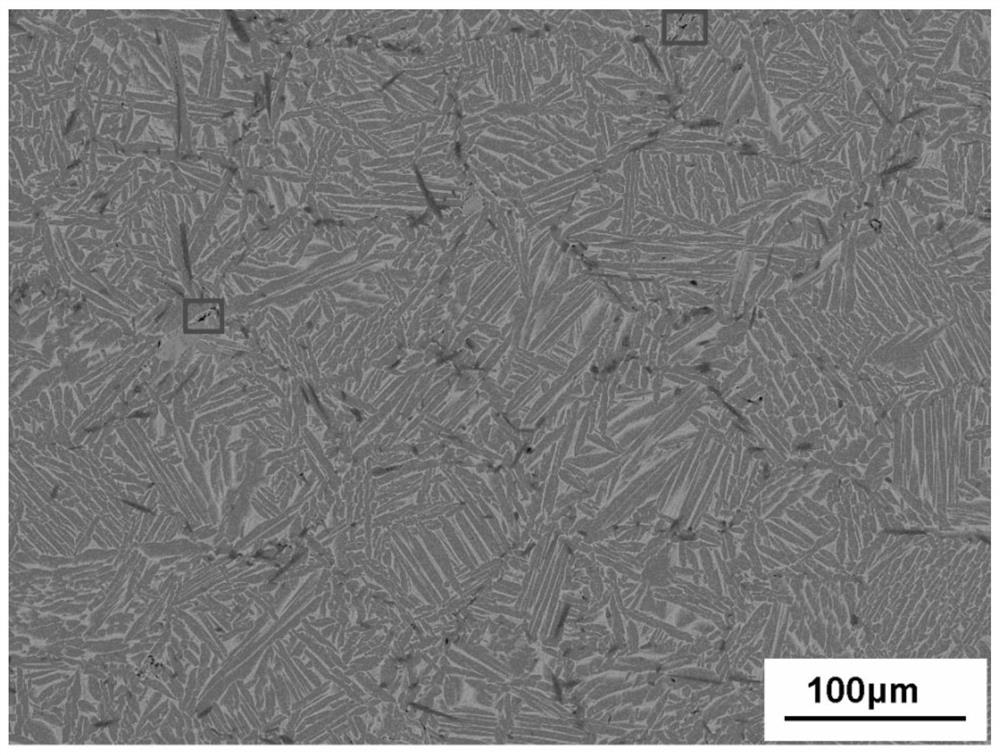

[0023] After mixing, the powder is sintered under the condition of 1400℃ / 30Mpa / 2h. The composition weight percentage of the composite material is Al: 6.20%, Mo: 3.8%, Zr: 4.10%, Sn: 1.80%, W: 1.20%, Si: 0.50%. , B: 1.00%, the balance is Ti and other unavoidable impurity elements, and the β-transition transition temperature of the alloy detected by metallographic method is 990°C. Such as Figure 1 As shown, there are unavoidable defects such as pores in the sintered composites.

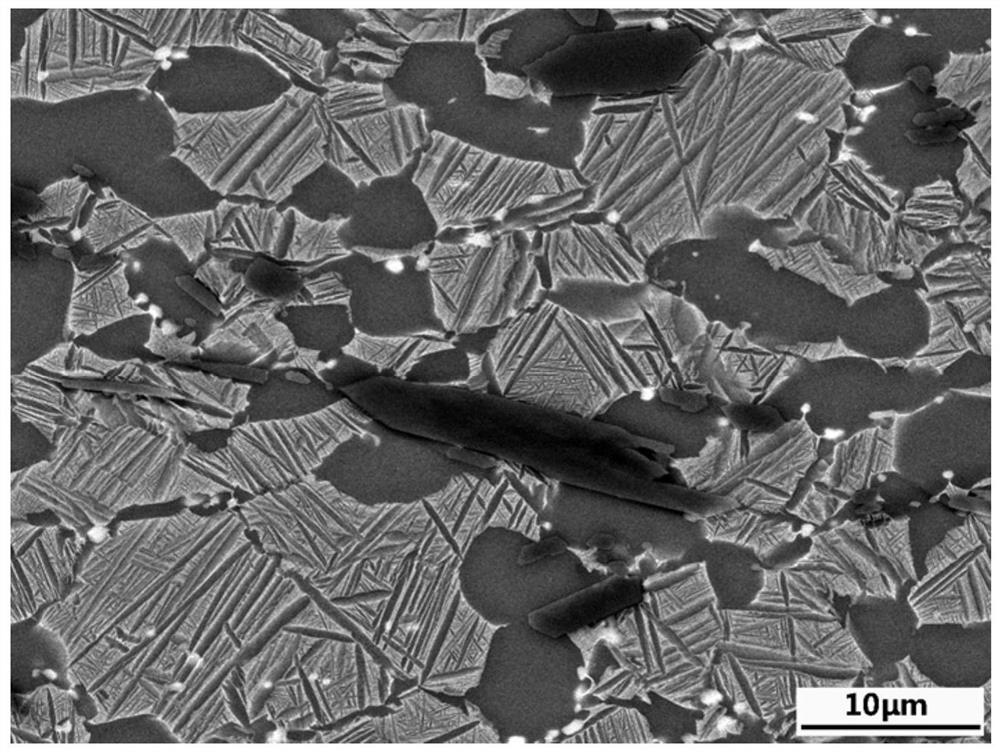

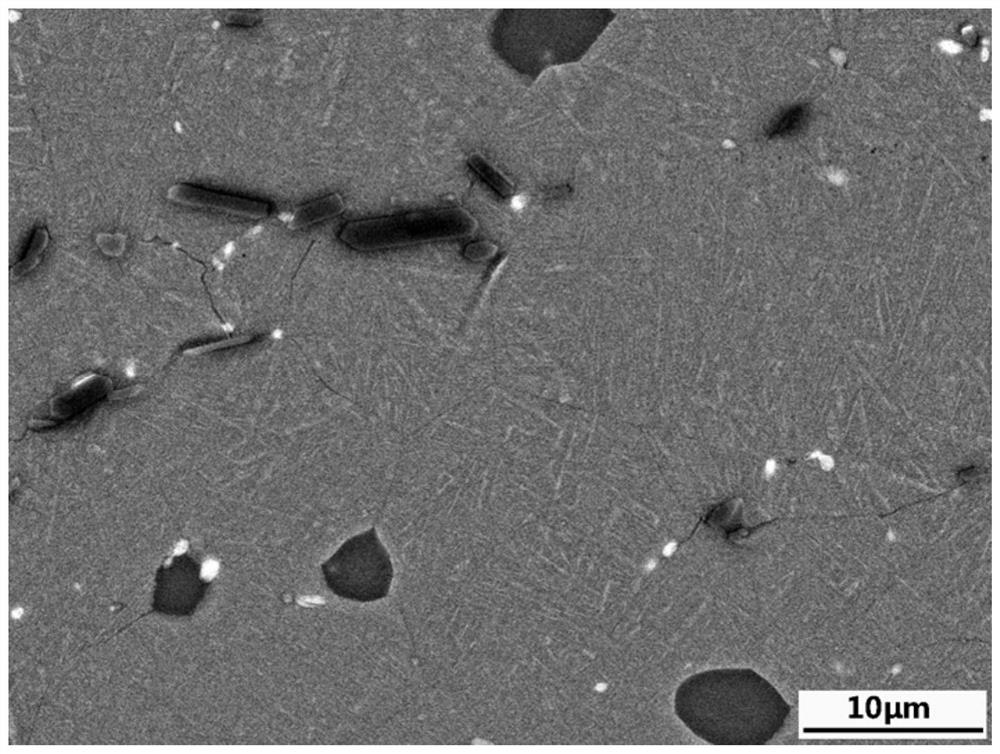

[0024] The sintered composite material at T β After heat preservation at +30°C for one hour, carry out hot pressing deformation, the deformation amount is 50%, and the tissue is densified after thermal deformation; β Heat treatment at +10°C, keep warm for 2 hours after heat penetration, and then slowly cool at a rate of 0.5°C / S; at T β Carry out the second heat treatment at -30°C, heat thoroughly and keep warm for 2 hours, then air cool; finally, carry out aging treatment at 550°C, keep warm for 12 ...

Embodiment 2

[0026] After mixing, the powder is sintered under the condition of 1300℃ / 50Mpa / 2h, and the composition weight percentage of the composite material is Al: 6.50%, Mo: 4.00%, Zr: 3.60%, Sn: 2.30%, W: 1.00%, Si: 0.30% , B: 1.50%, the balance is Ti and other unavoidable impurity elements, and the β-transition transition temperature of the alloy detected by metallographic method is 995°C. Such as Figure 1 As shown, there are unavoidable defects such as pores in the sintered composites.

[0027] The sintered composite material at T β After heat preservation at +10°C for one hour, carry out hot pressing deformation, the deformation amount is 50%, and the tissue is densified after thermal deformation; β Heat treatment at -10°C, keep warm for 2 hours after heat penetration, and then slowly cool at a rate of 1°C / S; at T β Carry out the second heat treatment at -30°C, after heat penetration, heat preservation for 2 hours, and then oil cooling; finally, aging treatment at 600°C, heat p...

Embodiment 3

[0029] After mixing, the powder is sintered under the condition of 1500℃ / 50Mpa / 2h. The composition weight percentage of the composite material is Al: 6.00%, Mo: 3.60%, Zr: 4.30%, Sn: 1.50%, W: 1.50%, Si: 0.50% , B: 2.00%, the balance is Ti and other unavoidable impurity elements, and the metallographic method detects that the β-transition transition temperature of the alloy is 1000°C. Such as Figure 1 As shown, there are unavoidable defects such as pores in the sintered composites.

[0030] The sintered composite material at T β +20℃ for one hour after hot pressing deformation, the deformation amount is 50%, and the tissue is densified after thermal deformation; then at T β Heat treatment at -20°C, keep warm for 2 hours after heat penetration, and then slowly cool at a rate of 1.5°C / S; at T β Carry out the second heat treatment at -50°C, after heat penetration, heat preservation for 2 hours, and then oil cooling; finally, aging treatment at 600°C, heat preservation for 24 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com