Ceramic material with amorphous/nanocrystalline structure and method of producing the same

A ceramic material and nanocrystalline technology, applied in the field of ceramic materials, can solve the problems of poor product performance, strong fatigue, high sintering temperature, and achieve the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

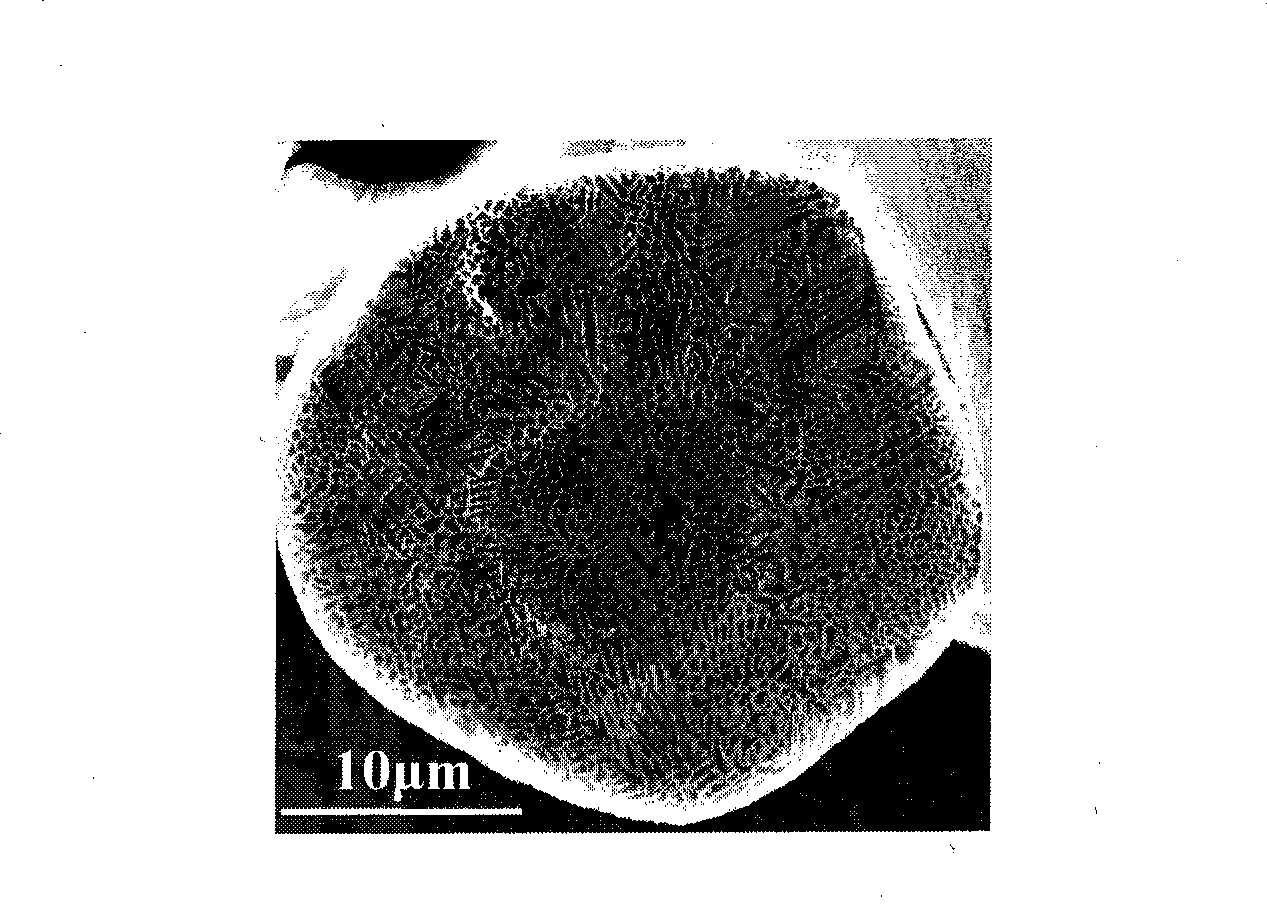

Image

Examples

Embodiment 1

[0034] This embodiment is realized according to the following steps:

[0035] 1. It is made by weighing 1 part of mixed ceramic powder, 0.4-1 part of deionized water and 0.01-0.015 parts of binder according to the ratio of parts by mass, wherein the mixed powder consists of 60%-99.9% of the main phase by mass percentage Ceramics (composed of 50% to 99% of nano-alumina and 1% to 50% of nano-titanium oxide) and 0.1% to 40% of additive phase ceramics, and the binder is polyvinyl alcohol;

[0036] 2. Use a ball mill to uniformly mix the above mixed ceramic powder, deionized water and binder to obtain a slurry;

[0037] 3. The slurry is spray-dried and then granulated to obtain nanocomposite powder. When the spray dryer is working, the inlet temperature is 210-240°C, the outlet temperature of the spray dryer is 100-120°C, and the nozzle speed of the spray dryer is 20000-36000r / min;

[0038] 4. Put the regranulated nano-composite powder into an alumina crucible, heat up to 1100-1...

Embodiment 2

[0042] The basic implementation steps of this embodiment are the same as those of Example 1. The difference from Example 1 is that the ceramic material is made of 1 part of mixed powder, 0.7 part of deionized water and 0.012 part of binder in terms of parts by mass. Others are the same as in Example 1.

Embodiment 3

[0044] The basic implementation steps of this embodiment are the same as those of Example 1, and the difference from Example 1 is that the mixed powder is composed of 60%-97% nano-alumina and 3%-40% nano-titanium oxide by mass percentage. Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com