Method and device for preventing thin-strip continuous casting molten bath surface from contaminating

A molten pool surface, continuous casting technology, applied in casting equipment, mechanical cleaning, manufacturing tools, etc., can solve the problems of casting interrupted belt, scum accumulation is difficult to control and not involved in the casting belt, and achieve the effect of improving the quality of the casting belt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

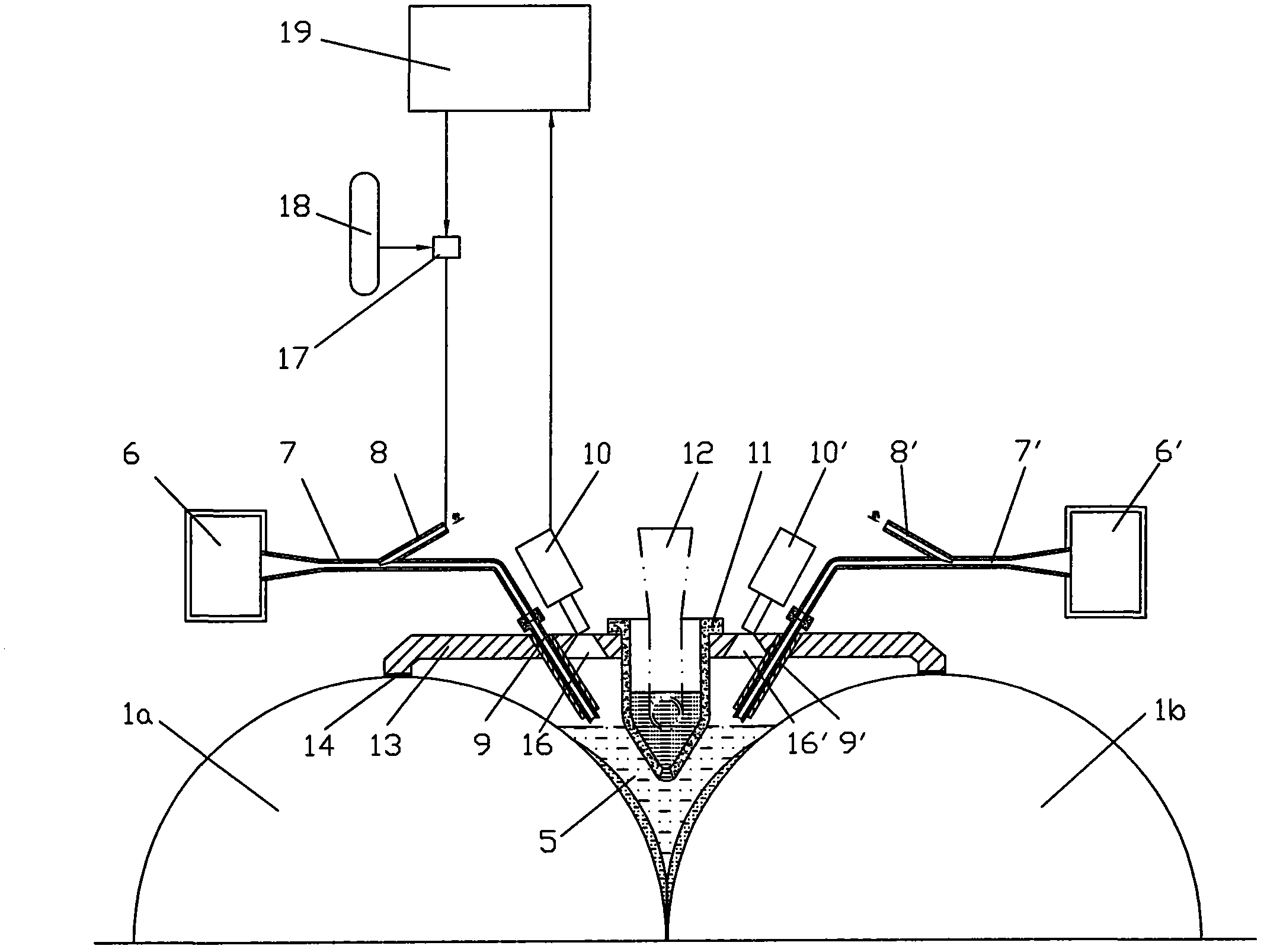

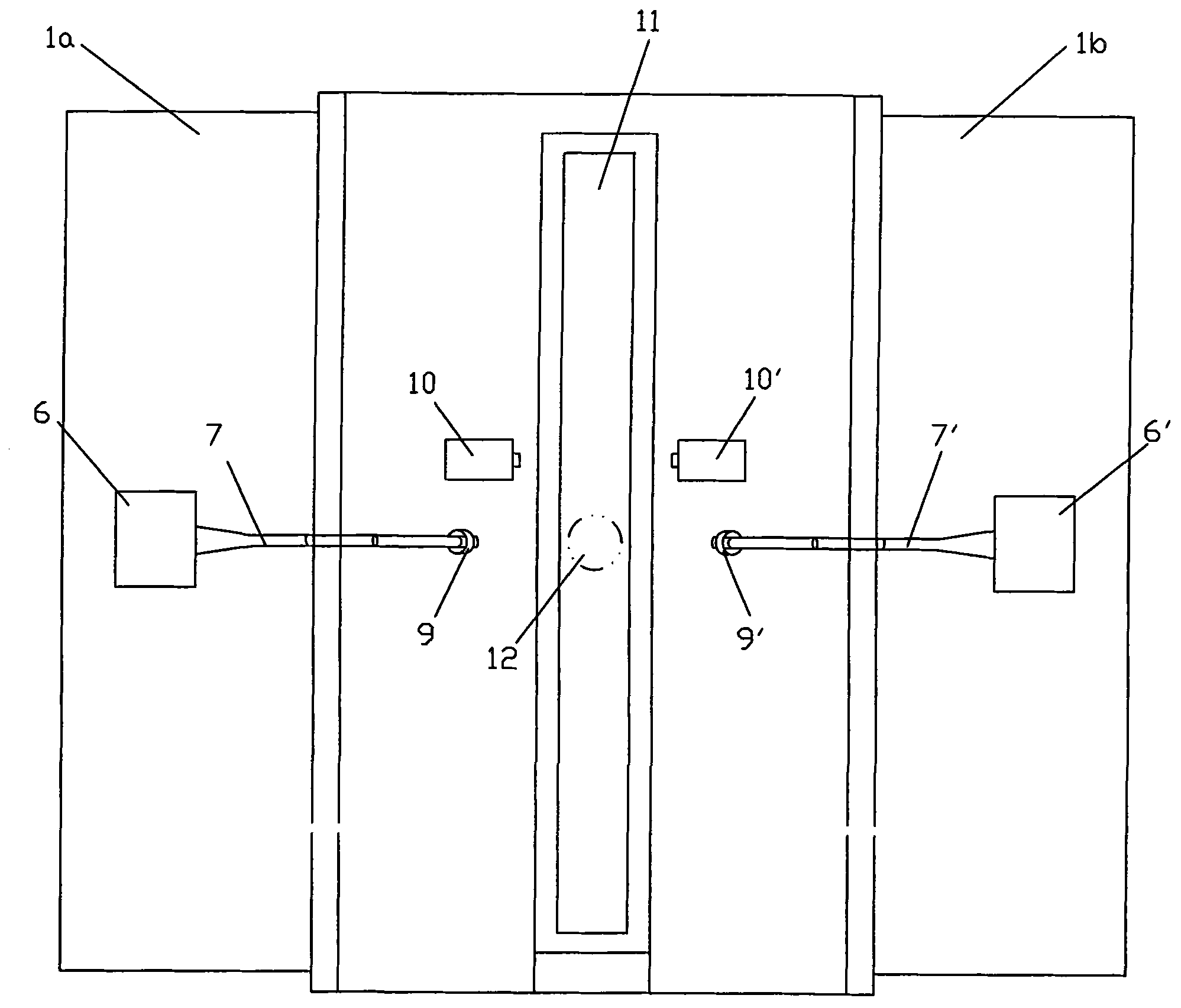

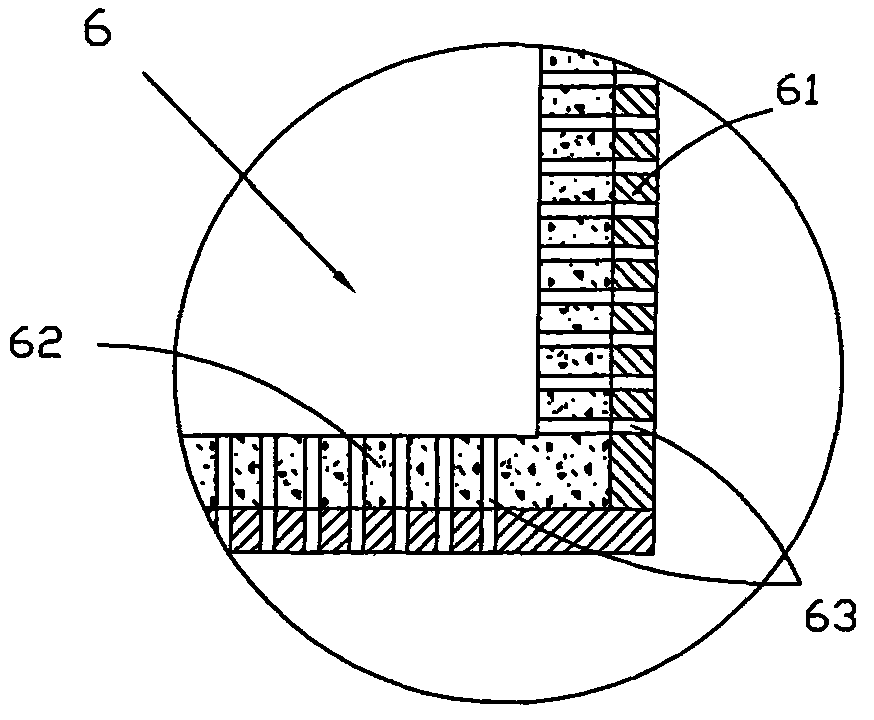

[0061] see Figure 1 ~ Figure 4 , the method for preventing the surface contamination of the thin strip continuous casting molten pool of the present invention, the molten pool level detection devices 10, 10' are arranged at the two ends of the molten pool 5, and the molten pools on the transmission side and the passive side of the casting rolls 1a, 1b are respectively observed 5. For the scum on the surface and the liquid level of the molten pool, if the distance between the edge of the monitored scum and the boundary line between the casting rolls 1a and 1b and the molten steel is less than 25mm, use the vacuum suction method to remove the scum from the molten pool through the scum removal device The surface is removed, thereby keeping the thin strip continuous casting bath clean, avoiding dross being involved in the solidified billet shell, and improving the cast strip quality. If the distance from the edge of the scum to the surface of the casting roll is greater than 65mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com