Automatic operation system and method of biologically refined herbal fibers

A technology of herbal fiber and operation method, which is applied in the chemical post-treatment of fiber, fiber treatment, fiber mechanical separation, etc., and can solve the problems of high labor intensity and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The automatic operation system for biorefined herbal fiber of the present invention can be used to carry out standard arrangement, inoculation, fermentation, inactivation, water treatment, Treatments such as oil stains and drying.

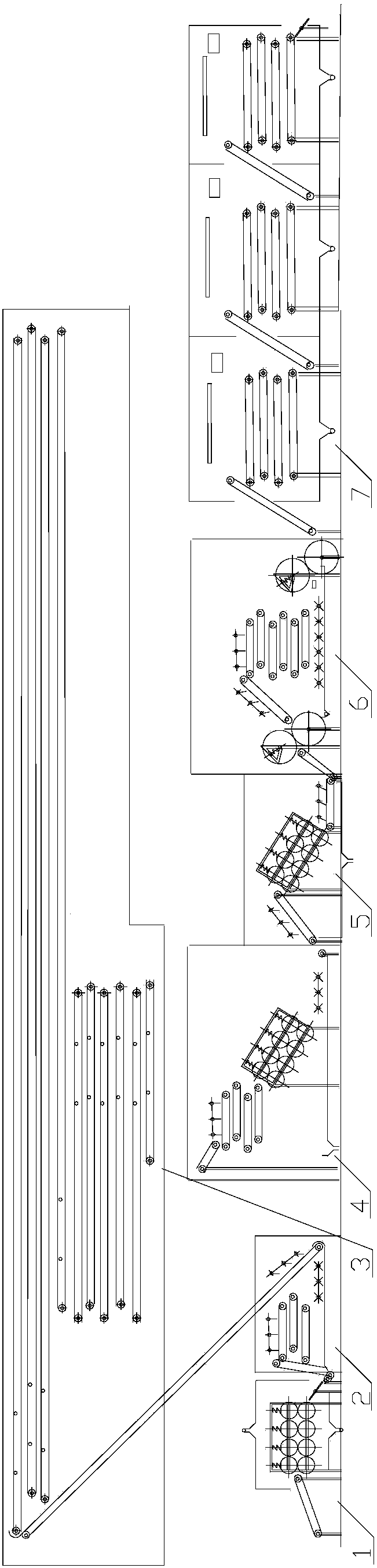

[0065] Such as figure 1 Shown, the automatic operation system of the biorefined herbal fiber of the present invention comprises sequentially arranged:

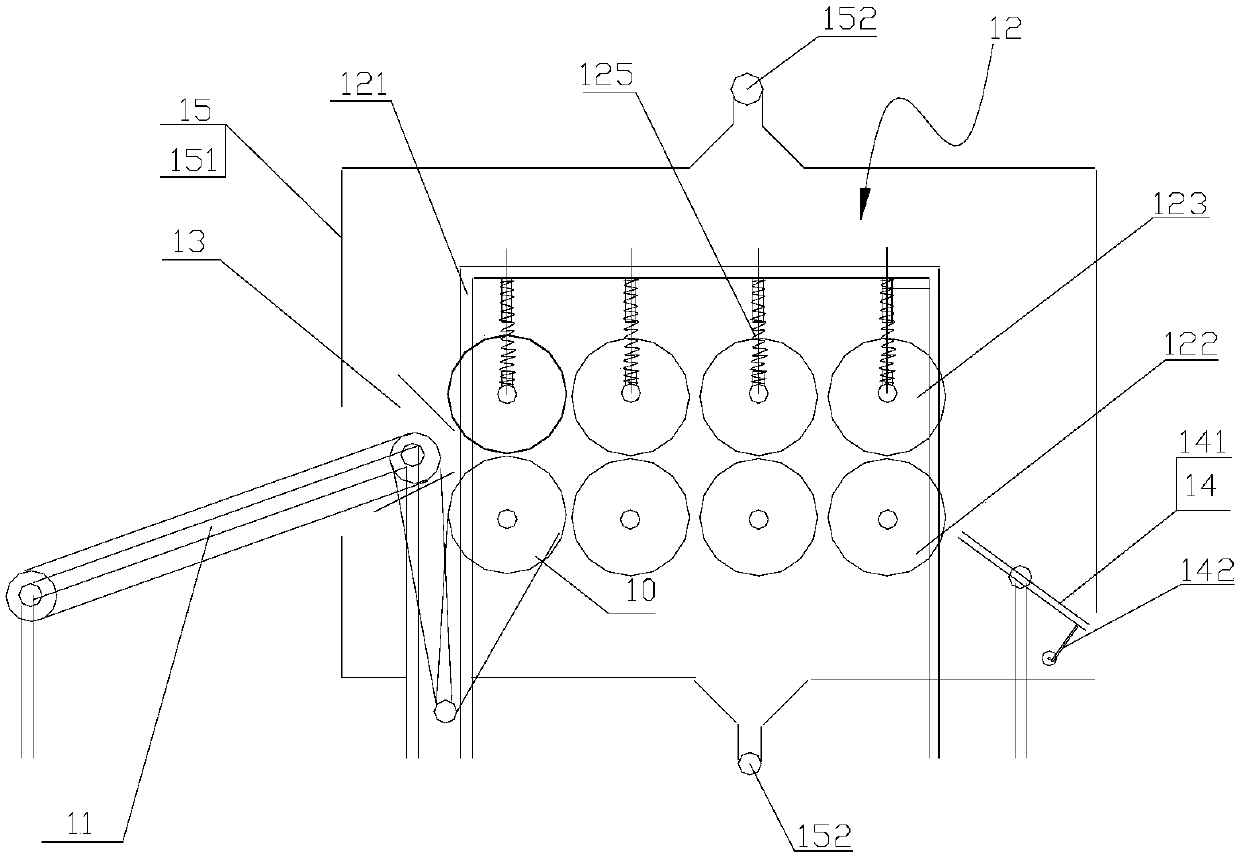

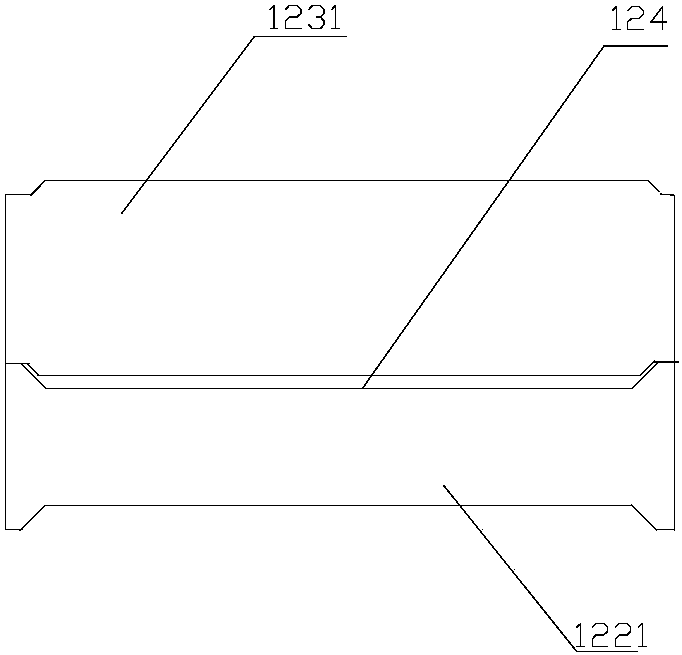

[0066] Herbal fiber raw material standard finishing equipment 1 includes an input device 11 that receives and delivers herbal fibers, a rolling device 12 that receives the herbal fibers delivered by the input device 11 and rolls the herbal fibers, and separates fiber bundle companions from fibers. Separation device 14 and dust collection device 15 for collecting dust and fiber bundle companions.

[0067] The dust removal device 15 of the herbal fiber raw material specification finishing equipment 1 can prevent debris and dust from spreading, and the dust removal device can also collect and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com