Vacuum mechanical dual-stirring casting method for preparing granule reinforced aluminium-base composite material

A particle-reinforced aluminum and composite material technology, applied in the field of vacuum-mechanical double-stirring casting method, can solve the problems of poor wettability of reinforcing particles and matrix melt, difficulty in entering and uniformly dispersing reinforcing particles, and high porosity of composite materials, and achieves enhanced Engaging and uniform dispersion efficiency, avoiding melt splash and gas entrainment, reducing the effect of impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

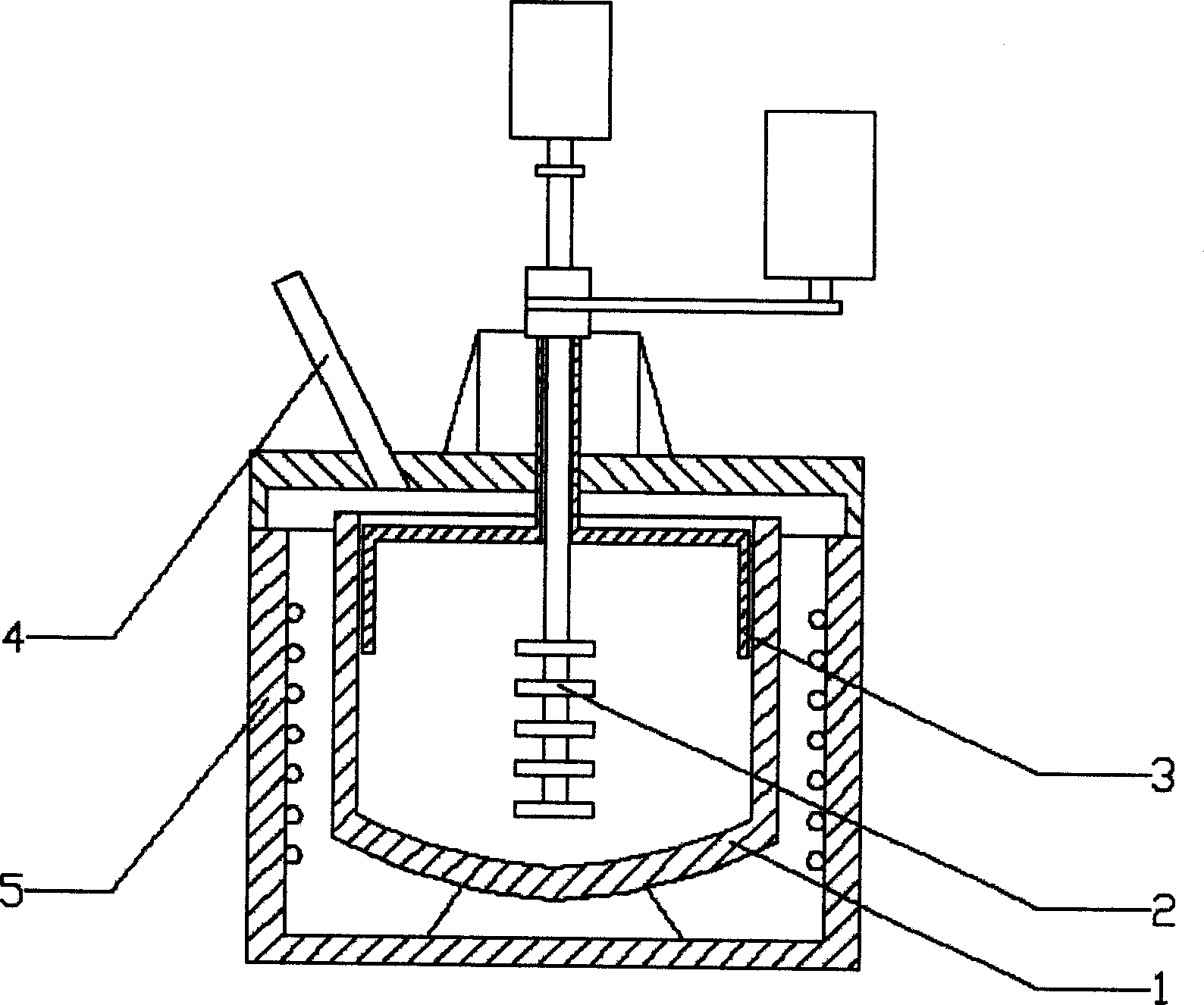

Image

Examples

Embodiment Construction

[0027] A specific embodiment in which silicon carbide is used as ceramic reinforcing particles, aluminum strontium is used as a modifier, and aluminum titanium boron is used as a refiner.

[0028] 1. Preparation

[0029] 1. Weigh 2.78kg of aluminum material and 750g of silicon carbide according to the weight ratio of silicon carbide and aluminum material of 1:4, the aluminum material is ZL101, and the particle size of silicon carbide is 20 microns.

[0030] 2. Weigh 20 g of aluminum strontium, aluminum titanium boron and 25 g of aluminum titanium boron according to the weight ratios of aluminum strontium, aluminum titanium boron and aluminum material of 0.1:25, 0.03:50, and 0.04:25 respectively.

[0031] 3. Sieve 750g of silicon carbide particles to remove agglomerated particle clusters and other impurities. Put the silicon carbide particles into the oven for pretreatment while the aluminum material is placed in the crucible. The temperature is 450°C to remove surface impuriti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com