Connection method for metal target material and target holder

A technology of metal target material and connection method, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problem that the bonding strength of the target and the target support is difficult to meet the requirements, and the butting surface of the target material and the target support is difficult to complete. Density, affecting sputtering heat conduction, etc., to avoid high environmental conditions, simple connection methods, and improve thermal and electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

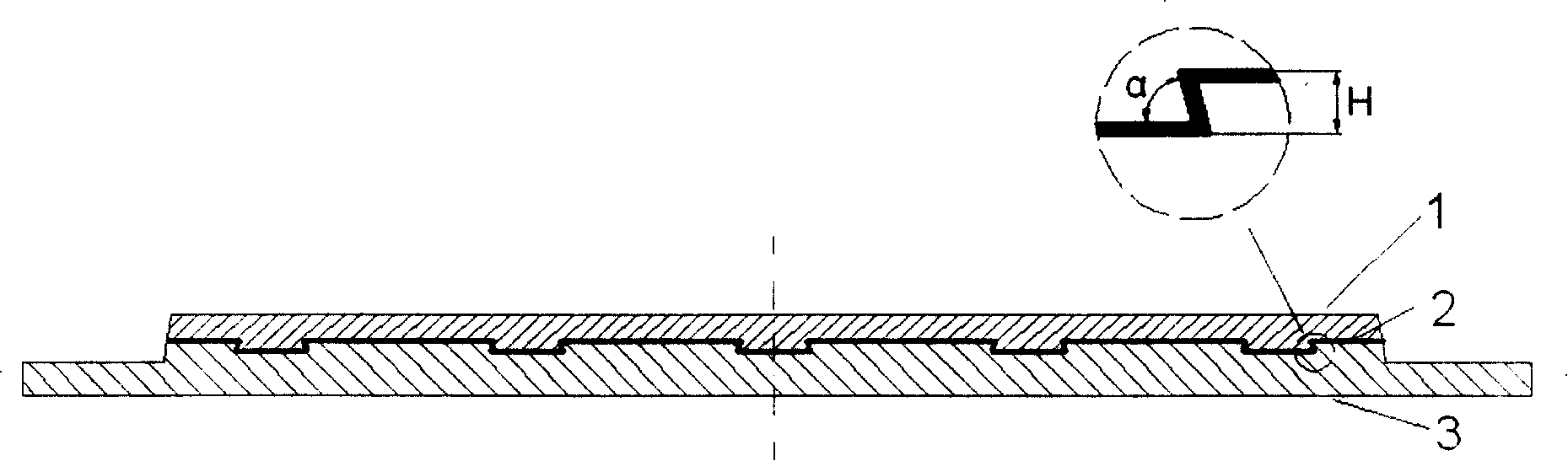

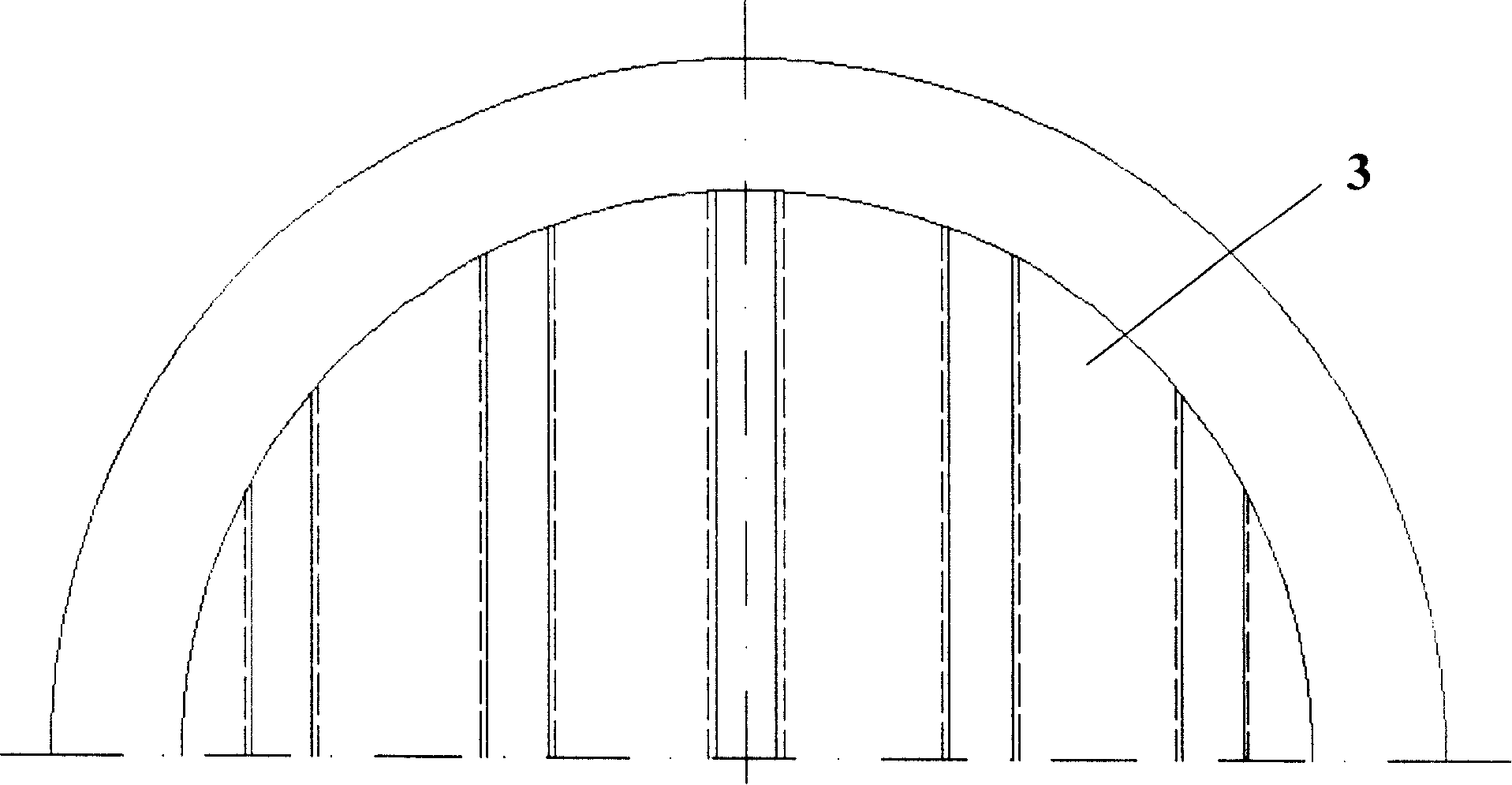

[0023] Such as figure 1 , 2 In the connection structure of the target material and the target support shown, the target material 1 and the target support 3 are welded and fixed by the filled brazing material 2 .

[0024] Al-Si alloy target material and Al alloy target holder combination is one of the most commonly used materials for making interconnection wires at present. During production, the target material 1 and target holder 3 are firstly processed by a milling machine. In the Al-Si target 5 dovetail-shaped bosses are processed on the butt joint surface of material 1. At the same time, five grooves of corresponding shapes are milled on the corresponding Al alloy target holder 3, the corresponding height H between the boss and the groove is 3 mm, and the inclination angle α between the contact side and the horizontal plane is 65°.

[0025] Clean the processed surfaces of the target material 1 and the target support 3. First degrease with acetone, wash with pure water, ...

Embodiment 2

[0029] The combination of high-purity Ti target material and oxygen-free copper target holder is often used to prepare one of the film materials for the barrier layer of integrated circuits, and its structure is the same as that of Embodiment 1. During production, the target 1 and the target holder 3 are respectively processed with a milling machine, and 6 inverted trapezoidal bosses are processed on the butt joint surface of the high-purity Ti target. At the same time, for the oxygen-free copper target holder, 6 grooves are milled correspondingly, the height H is 5mm, and the inclination angle α is 80°.

[0030] The processed surfaces of the target material 1 and the target support 3 are cleaned with acetone, nitric acid solution, pure water, etc., and then dried with hot air. The target holder 3 is heated to 250°C, and 0.3mm of Sn-Cu alloy brazing material 2 is coated on the surface of the target holder 3, and its liquidus temperature is about 200°C.

[0031] The target mat...

Embodiment 3

[0033] The high-purity Ti-W alloy target and the brass target-support joint are another material commonly used in the preparation of barrier films for integrated circuits, and their structure is the same as in Example 2. During manufacture, the target 1 and the target holder 3 are respectively processed with a milling machine, and three inverted trapezoidal bosses are processed on the butt joint surface of the Ti-W alloy target. At the same time, three grooves are correspondingly milled out for the brass target holder 3, the height H is 2 mm, and the inclination angle α is 70°.

[0034] The processed surfaces of the target material 1 and the target support 3 are cleaned with acetone, nitric acid solution, pure water, etc., and then dried with hot air. The target holder 3 is heated to 230°C, and 0.5mm of Sn-Ag-Cu alloy brazing material 2 is coated on the surface of the target holder 3, and its liquidus temperature is about 220°C.

[0035] The target material 1 is gradually squ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com